Eccentric wheel type piston engine

A technology of piston engine and eccentric wheel, which is applied in the direction of eccentric wheel, engine components, machine/engine, etc. It can solve the problems of zero parts, large number of parts, high manufacturing cost, and technical difficulty, so as to reduce engine vibration and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

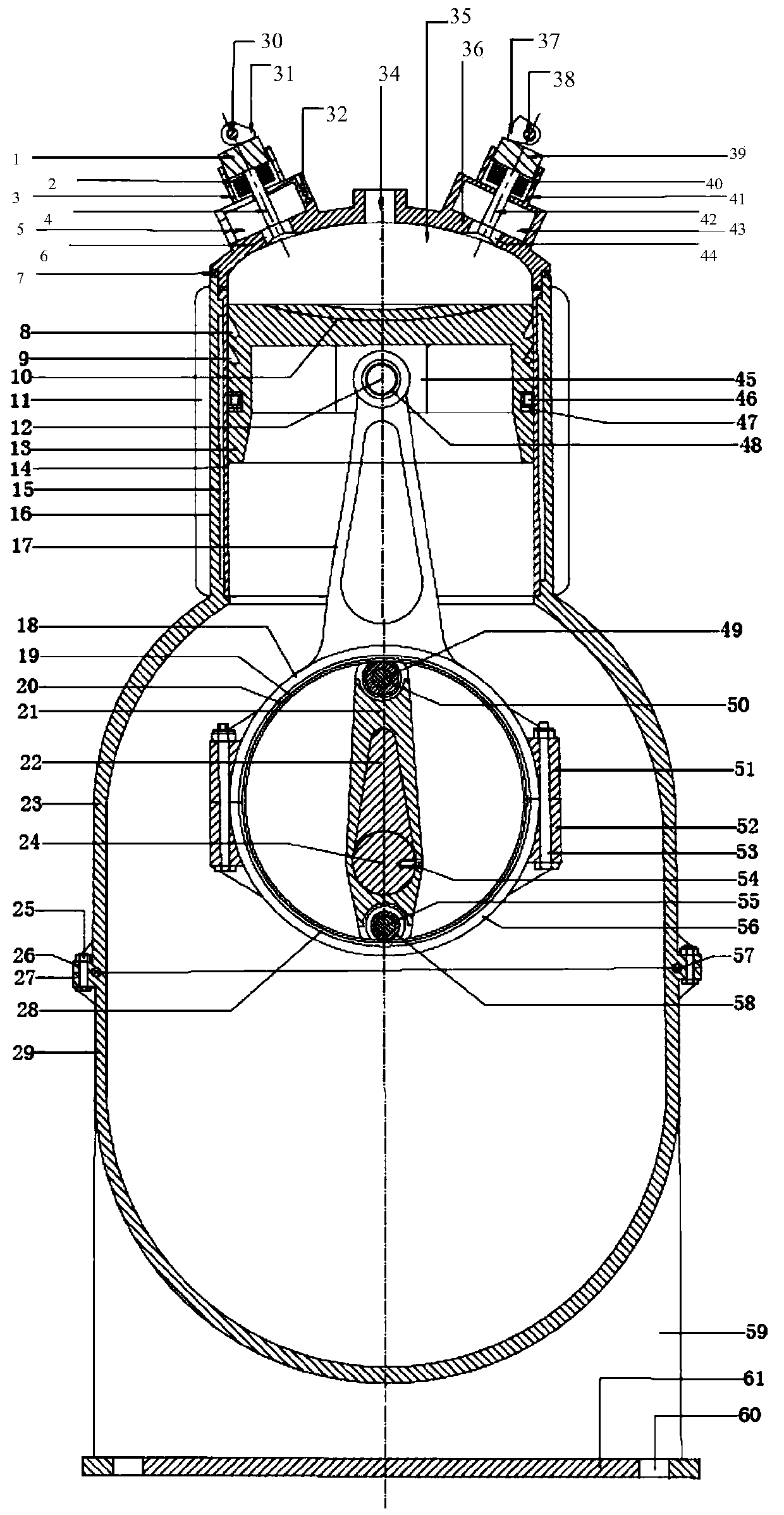

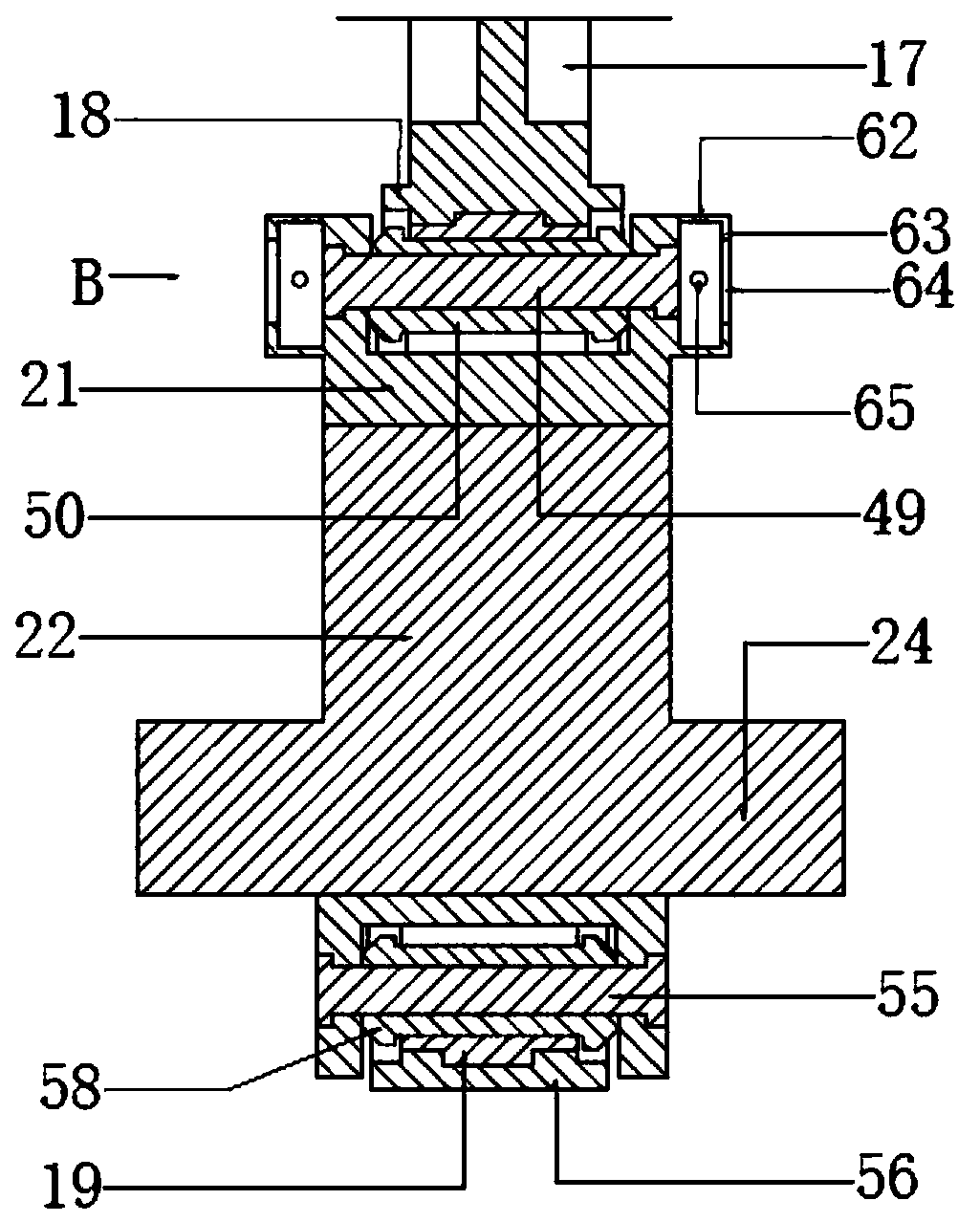

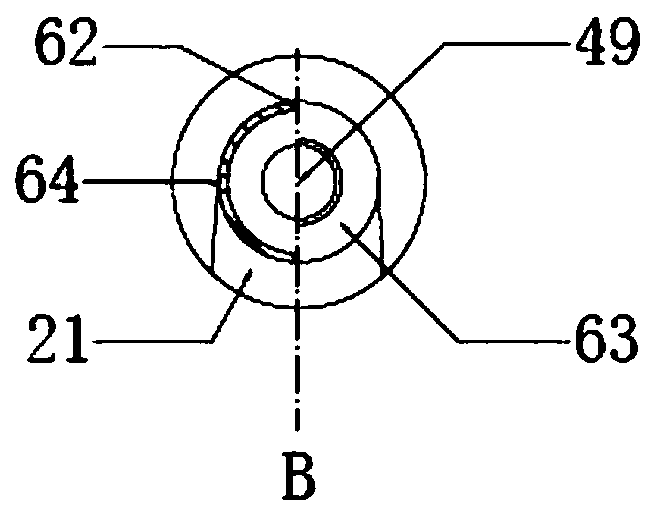

[0018] see Figure 1 to Figure 3 As shown, the disclosure of the present invention describes the preferred embodiments of the present invention below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0019] Below in conjunction with accompanying drawing, structural principle of the present invention is further described:

[0020] The engine of the present invention is designed according to the principle of 360° eccentric circular movement of the through shaft, and its structural working principle is as follows; The wheel body 21 drives the eccentric main wheel 50 and the eccentric auxiliary wheel 58 to roll the track ring 19 according to the rotation direction of the input power, and the track ring 19 transmits the force to the upper outer ring 18 and the lower outer ring 56 under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com