Oil separation device, compressor and vehicle with compressor

A technology for oil separation and compressors, which is applied to vehicle parts, parts of pumping devices for elastic fluids, mechanical equipment, etc. It can solve the problem of affecting the space size of refrigeration devices, failing to meet the oil-gas separation effect, and the cost of rotary compressors. Advanced problems, to achieve the effect of good practicability, small footprint and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

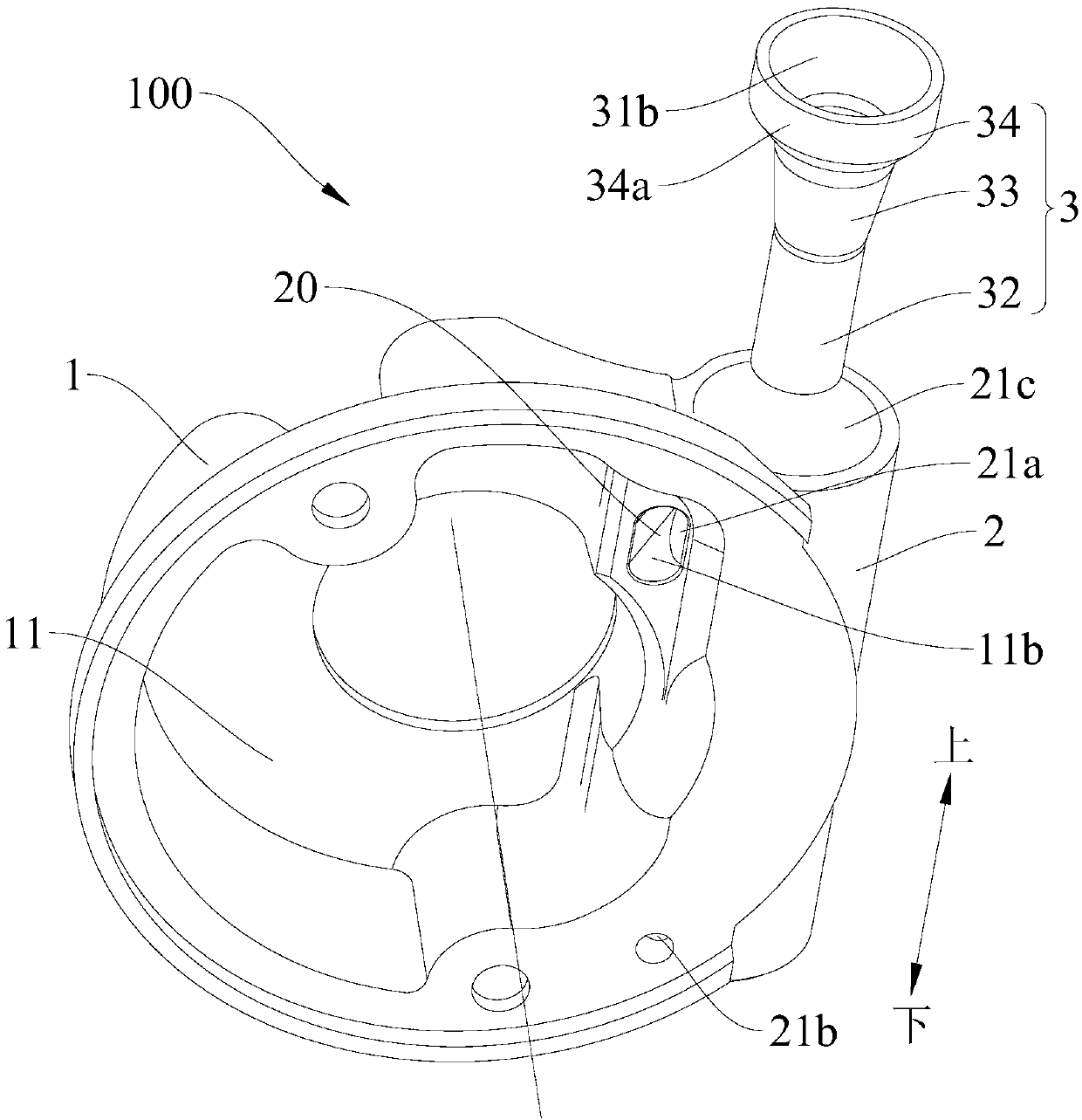

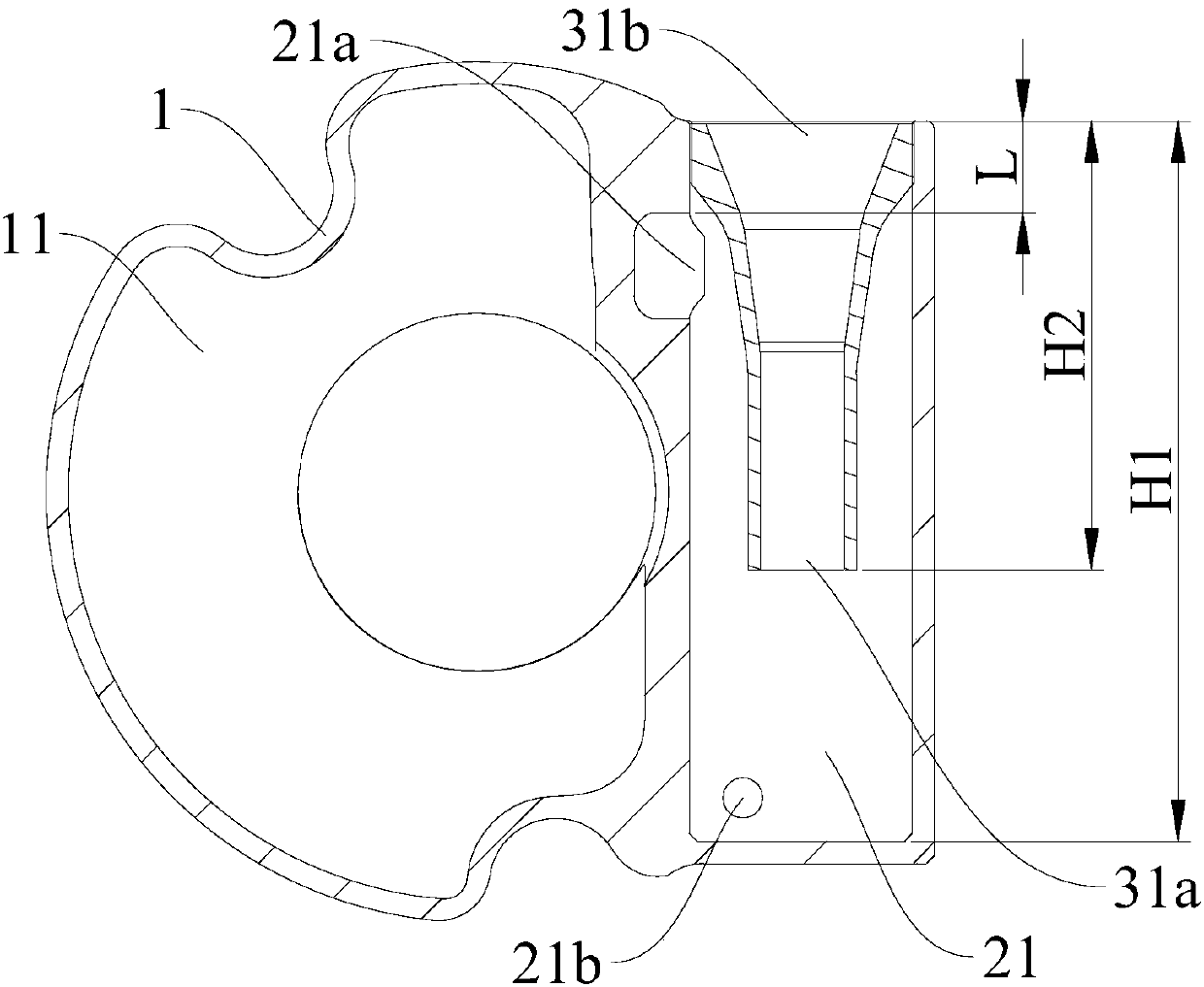

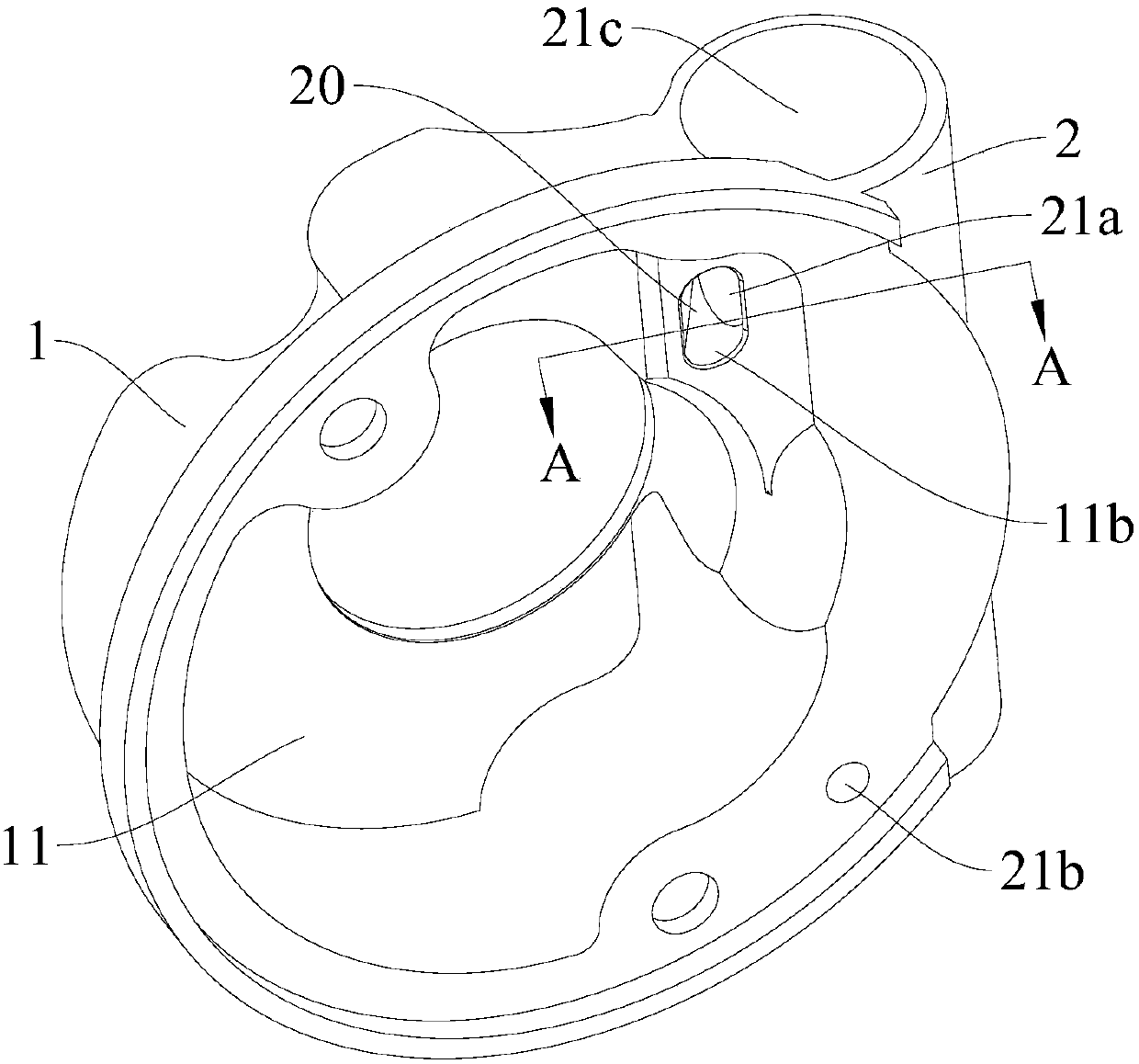

[0087] In this example, if Figure 1-Figure 5As shown, the oil separation device 100 includes a first housing 1 , a second housing 2 and an oil separation insert 3 . A first chamber 11 is defined in the first housing 1, and a first air inlet 11a and a first air outlet 11b communicating with the first chamber 11 are formed on the inner wall of the first housing 1. The first air inlet 11a is located on one axial side of the first housing 1, and the other axial side of the first housing 1 is closed; the second housing 2 is arranged on the outer wall of the first housing 1, and the second housing 2 defines a The second chamber 21 and the volume of the second chamber 21 is smaller than the volume of the first chamber 11, the second housing 2 is provided with an air inlet passage 20 to communicate with the first chamber 11 and the second chamber 21, the second A second air inlet 21a and an oil discharge port 21b communicating with the second chamber 21 are formed on the inner wall ...

Embodiment 2

[0094] Such as Image 6 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the intake passage 20 is provided on the first housing 1 to communicate with the first chamber 11 and the second chamber 21.

Embodiment 3

[0096] Such as Figure 7 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that: the first pipe section 32 and the third pipe section 34 are generally formed in a cylindrical shape, the first The cross-sectional area of the pipe section 32 is smaller than the cross-sectional area of the third pipe section 34, and the second pipe section 33 is roughly formed as a conical cylinder; the angle between the central axis of the second housing 2 and the rotation axis of the crankshaft 102 is a non-right angle, for example, The central axis of the second housing 2 may be arranged parallel to the rotation axis of the crankshaft 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com