Method for detecting relative mass correction factor of impurity derivative chromatogram response of sample with not high purity

A technology of correction factor and relative mass, which is used in measuring devices, instruments, scientific instruments, etc. to ensure the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

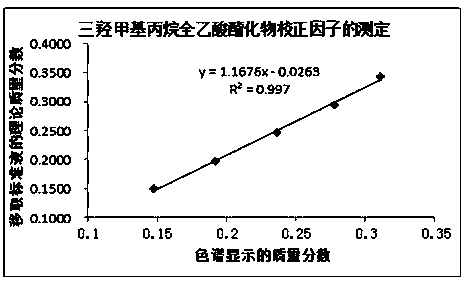

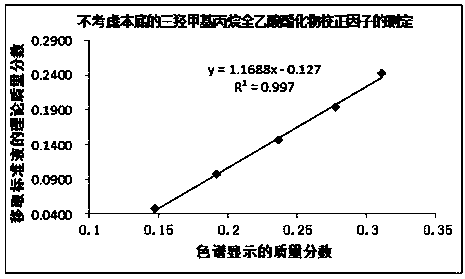

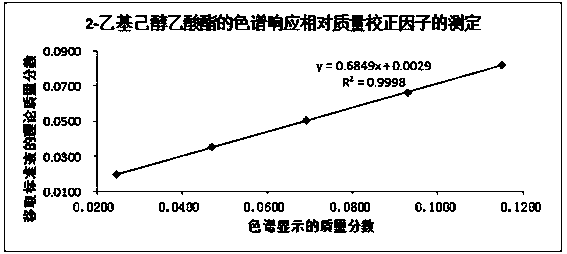

Embodiment 1

[0055] Step 1. The boiling point of ditrimethylolpropane under normal pressure is 435.6°C, which cannot be directly measured by gas chromatography. Accurately weigh 2.4956g of ditrimethylolpropane which has been refined and whose mass fraction of the main component is higher than 95%. Put propane in a 50mL flat-bottomed glass tube with a ground mouth, transfer 25mL (calculated excess) acetic anhydride selected as a derivatization reagent, put the glass tube into a matching electric heating aluminum bath reactor, and select 142°C for derivatization Chemical reaction, the upper part of the reactor is equipped with an air condenser tube, so that the volatile matter can be condensed and recovered. After the reaction is complete for 1 hour, the glass tube is taken out. Cool to room temperature, and open the ground plug on the top of the condenser tube every five minutes to ensure that the liquid droplets condensed on the wall of the condenser tube can flow back to the reactor under ...

Embodiment 2

[0104] Step 1, the known industrialized production of trimethylolpropane contains impurities with higher boiling points under normal pressure such as ditrimethylolpropane (Di-TMP), TMF, etc., so it is necessary to accurately measure trimethylolpropane with a gas chromatograph propane, also need to use indirect method, use acetic anhydride to esterify trimethylolpropane and its impurities into substances with lower boiling point, and accurately weigh 1.9795g of refined and the mass fraction of the main component is higher than 99%. In a 50mL flat-bottomed glass tube with ground mouth, transfer trimethylolpropane to 25mL (calculated excess) acetic anhydride as a derivatization reagent, put the glass tube into a matching electric heating aluminum bath reactor, select The derivatization reaction is carried out at 142°C. The upper part of the reactor is equipped with an air condenser, so that the volatiles can be condensed and recovered. After 1 hour of complete reaction, the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com