Die monitoring system and method

A monitoring system and mold technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve problems such as aggravating work intensity, affecting work efficiency, and heavy computer workload, reducing false alarms and improving detection accuracy. Effect

Active Publication Date: 2019-09-20

漳州智觉智能科技有限公司

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the continuous operation of the injection molding machine, day and night alternate, coupled with weather changes, coupled with unstable power supply of the factory, cross-interference of various light sources in the factory

The vision-based injection protection device is a detection device based on template image comparison. When the light source changes too much, the video detection protector using a single template often falsely alarms.

Especially some injection molding machines have open spaces, sunny windows or transparent ceilings can directly shine on the injection molding machine, strong light changes, forming changing shadows on the mold, resulting in the failure of the detection of the video protection device

The current popular practice is that the operator updates the template when a false alarm occurs. Due to the different weather and time every day, the template needs to be updated many times, which increases the work intensity, and the false alarm also affects the work mood.

Another method is to accumulate a large number of benchmark templates, dozens or hundreds of them, and compare them one by one with all these templates each time. The amount of calculation is huge, and the calculation time is long, which affects work efficiency. At the same time, the computer workload is too high and the temperature is too high. , which shortens the working life of the device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

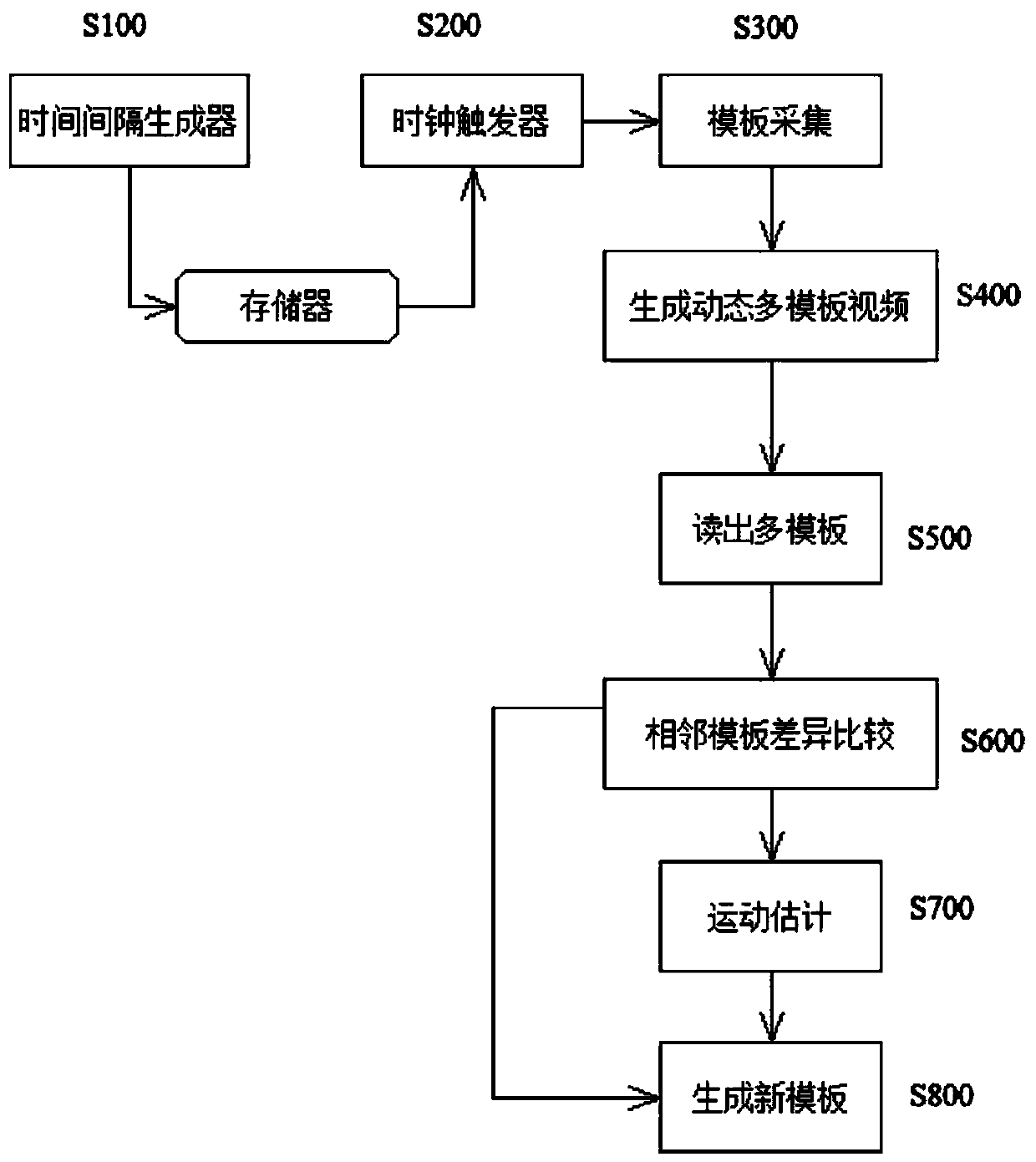

[0103] As an embodiment of the present invention, the mold monitoring and protection method includes: monitoring and testing process;

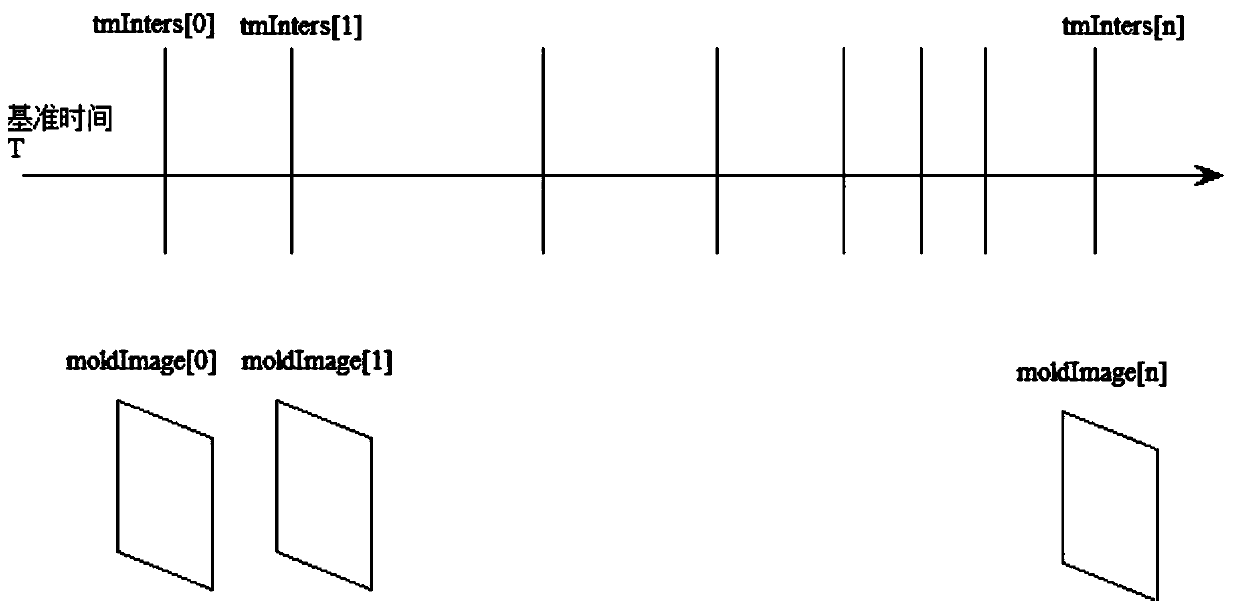

[0104] In the actual monitoring and detection stage, the clock trigger needs to read out the readout time interval one by one from Ft, and read out the template image from Fm at the same time.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

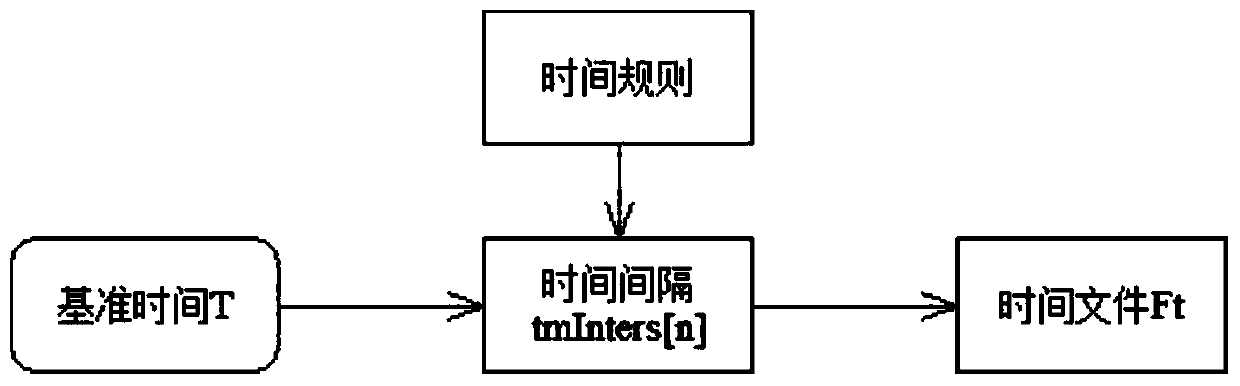

The invention discloses a die monitoring system and method and a die template image generation system and method. The die monitoring system comprises a time interval storage module, a template storage module, a template acquisition module, a template reading module and a template difference comparison module. The time interval storage module is used for storing the acquisition interval data of each time period, the template storage module is used for storing the dynamic template video files formed by the template images at various time points, and the template acquisition module is used for acquiring the template images according to the acquisition interval data stored in the time interval storage module; the template reading module is used for reading the corresponding template images from the template storage module, each template image corresponds to a time point, and the template difference comparison module is used for comparing the template image acquired in real time with the template image at the corresponding time point in the template storage module to obtain a comparison result. According to the present invention, the detection accuracy can be improved, the false alarm is reduced, and meanwhile the detection efficiency is not affected.

Description

technical field [0001] The invention belongs to the technical field of injection molds, and relates to an injection mold device, in particular to a timeline sequence multi-template mold monitoring system and method. Background technique [0002] Injection molds are the most important molding equipment for injection molding products, and their quality is directly related to the quality of products. Moreover, since the mold occupies a large proportion of the production cost of the injection molding processing enterprise, its service life directly affects the cost of the injection molding product. Therefore, improving the quality of injection molds, maintaining and maintaining them through photoelectric technology, and prolonging their service life are important issues for injection molded product processing companies to reduce costs and increase efficiency. Injection molding product processing enterprises have many types of products and frequent mold replacement. In a product...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06T7/00G06T7/254G06K9/00

CPCG06T7/001G06T7/254G06T2207/10016G06T2207/30108G06V20/52

Inventor 游旭新

Owner 漳州智觉智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com