Integrated circuit manufacturing device and method

A technology for integrated circuits and manufacturing devices, which is applied in circuits, semiconductor/solid-state device manufacturing, resistors, etc., can solve the problems of inability to improve the yield of integrated circuit substrate preparation devices, and achieve convenient production and use, improve production efficiency, and facilitate use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

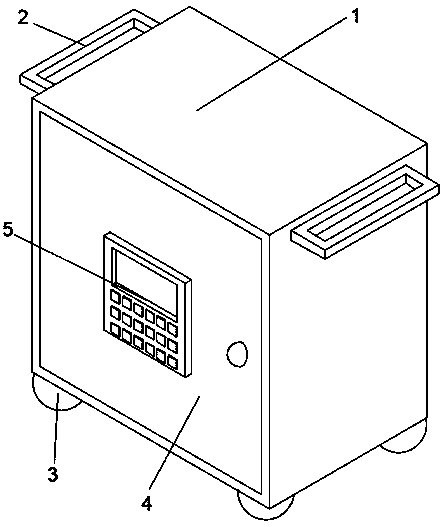

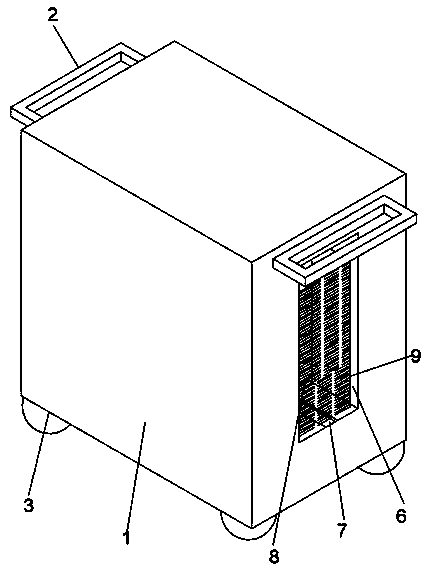

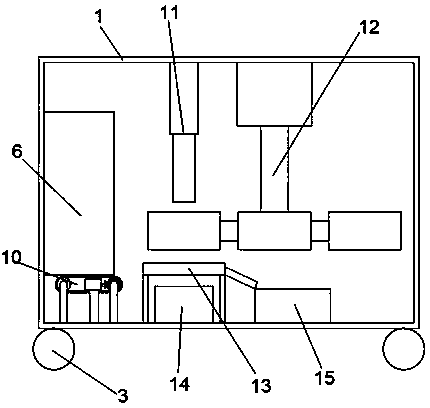

[0032] Embodiment 1: refer to Figure 1-3 ;

[0033] An integrated circuit manufacturing device includes an ion sputtering machine and a packaging machine, and also includes a substrate preparation machine. The substrate preparation machine is provided with a substrate preparation box 1, and the bottom surface of the substrate preparation box 1 is fixedly equipped with a moving wheel 3. The substrate preparation box 1. There are handles 2 on the upper ends of the left and right sides. The front of the substrate preparation box 1 is movably connected with the box door 4. A control panel 5 is installed on the outer surface of the box door 4. An intelligent production system is installed inside the control panel 5. The left side surface of the substrate preparation box 1 The middle part is provided with a side slot 6, and the lower slot surface of the side slot 6 is provided with a lower notch 7, and the inner slot surface of the side slot 6 is provided with a side slot 8, and a ...

Embodiment 2

[0035] Embodiment 2: refer to Figure 4 , the basis of the embodiment 1 is different in that;

[0036] The pushing mechanism 10 includes a first roller sleeve 16, a second roller sleeve 17 and a rolling platform 20, the peripheral surface of the first roller sleeve 16 is movably connected with the inner surface of one side of the rolling platform 20, and the peripheral surface of the second roller sleeve 16 is It is movably connected with the inner surface on the other side of the rolling table 20, and the middle part of the upper surface of the rolling table 20 is fixedly connected with a push block 24, which matches the lower notch 7, and the two ends of the first roller sleeve 16 are rotatably connected with the second One support connecting shaft 18, the lower end of the first supporting connecting shaft 18 is fixedly connected with the inner bottom surface of the substrate preparation box 1, the two ends of the second roller sleeve 17 are rotatably connected with the seco...

Embodiment 3

[0039] Embodiment 3: refer to Figure 5 , the basis of the embodiment 1 is different in that;

[0040] The fixed mechanism 13 includes a fixed frame 25, the lower surface of the fixed frame 25 is fixedly connected with the inner bottom surface of the substrate preparation box 1 through the support legs 26, the upper and lower sides and the left and right sides of the fixed frame 25 are all connected, and the front and rear lower frames of the fixed frame 25 are fixedly installed with Induction transmission table 27, induction transmission table 27 is electrically connected with control panel 5, electric control hydraulic rod 28 is fixedly installed on the front and rear upper frame surfaces of fixed frame 25, and the lower end of electric control hydraulic rod 28 is fixedly connected with a pressure plate for fastening large substrate 9 29. The right end of the fixed frame 25 is provided with a prolongation groove 30 for the circulation of waste boards. The prolongation groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com