Automobile PU foaming mold cavity surface ceramic plating process

A technology for foaming molds and automobiles. It is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. It can solve the problems of harmful odor of coating, high maintenance cost, and lower product qualification rate, so as to benefit the product. The effect of demoulding, reducing maintenance costs and improving the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

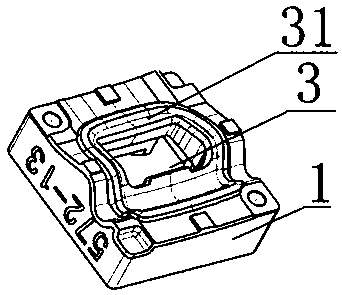

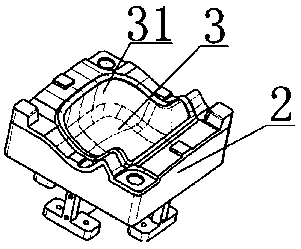

[0018] Refer to attached Figure 1-2 , Example 1

[0019] A kind of porcelain plating process on the surface of the PU foam mold cavity of automobile headrest, the steps are as follows,

[0020] 1) Clean and degrease the surface of the automotive PU foam mold cavity, heat the mold to 385°C and keep it warm for 30 minutes;

[0021] 2) Sand blasting treatment, using 100 mesh quartz sand blasting treatment;

[0022] 3) After lowering the mold temperature to 50°C, start spraying the ceramic coating, and spray evenly through the coating tool, spray once, and the thickness of the coating formed by spraying is 40 microns;

[0023] 4) After spraying, heat the mold to 120°C and keep it warm for 10 minutes. Continue to heat the mold to 180°C and keep it warm for 10 minutes. Finally, heat the mold to 230°C and then vitrify it for 30 minutes. Cool naturally to complete the porcelain plating .

[0024] The automobile PU foaming mold is an automobile headrest mould, an automobile armres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com