Method for measuring unevenness of glass plate by combining single camera with two-dimensional code

A two-dimensional code and glass plate technology, applied in the field of visual measurement, can solve the problem of large volume of the measurement system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

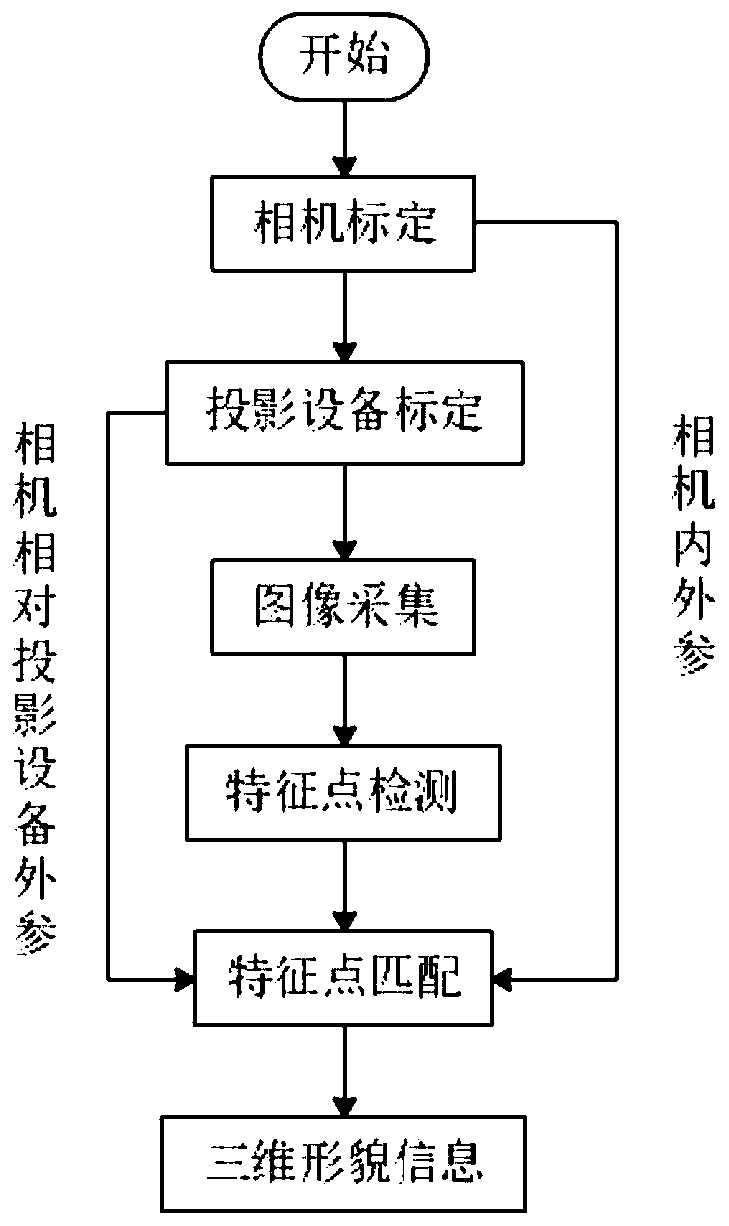

[0081] like figure 1 As shown, a method for measuring the unevenness of a glass plate with a single camera combined with a two-dimensional code includes the following subdivision steps:

[0082] Step 1: Camera Calibration

[0083] The camera calibration of the present invention adopts Zhang Zhengyou's two-dimensional target calibration method. The entire working range is set to 1-3m. In order to meet the measurement requirements, after considering the field of view, focal length and other parameters, a CMOS industrial digital camera with a USB2.0 interface and a fixed focal length lens with a focal length of 16mm are selected.

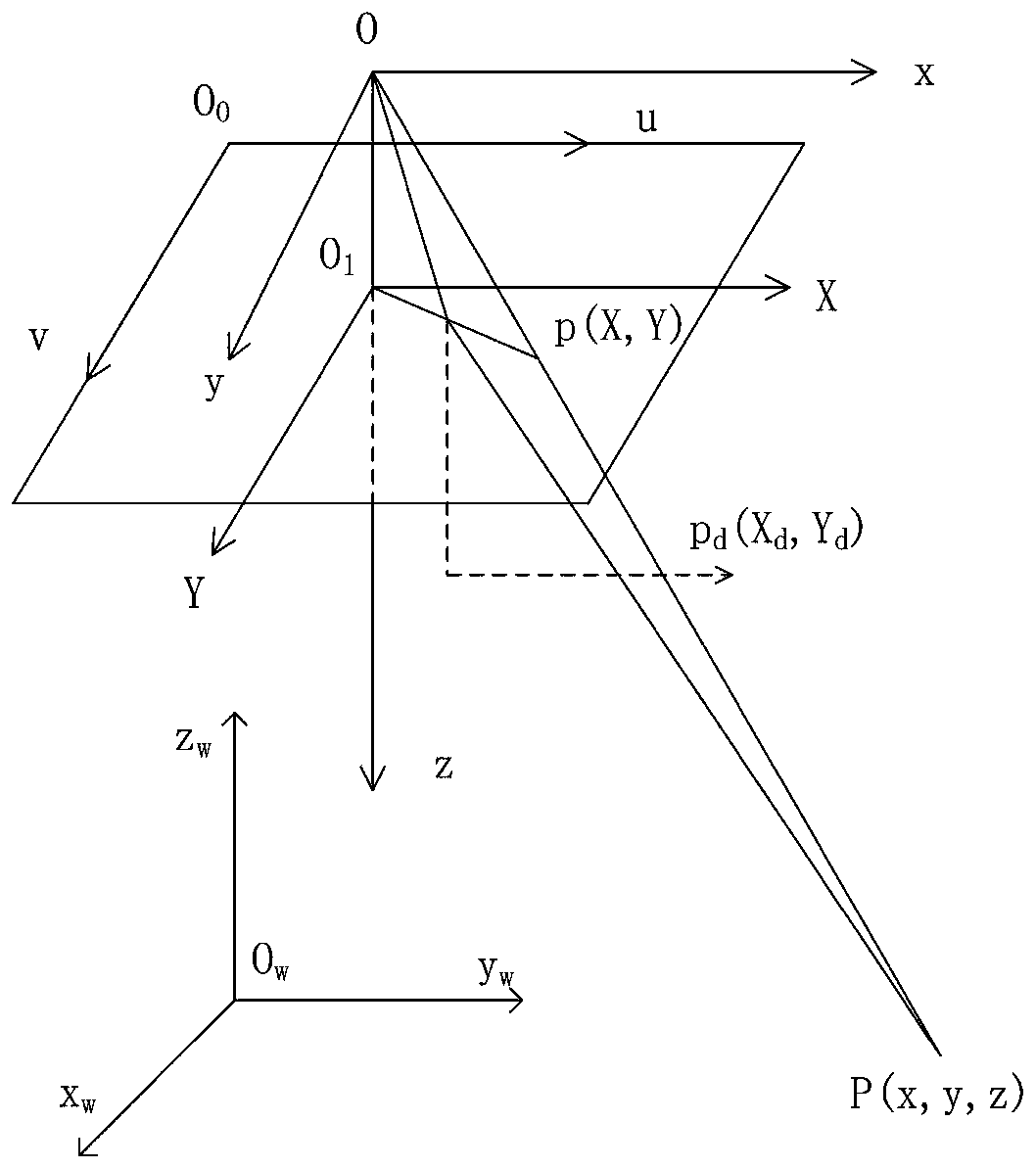

[0084] Step 1.1 see figure 2 As shown, the mapping relationship between the two-dimensional coordinates and the three-dimensional coordinates is established, and the imaging position of any point P in the space can be approximated by the pinhole model.

[0085] The homogeneous coordinates of the space point P in the world coordinate system and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com