3D NAND memory cell module, memory and manufacturing method

A 3DNAND, memory cell technology, applied in electrical components, electro-solid devices, semiconductor devices, etc., can solve problems such as the inability to further improve the electron mobility of 3DNAND flash memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following description, several specific details are set forth. However, embodiments as described herein may be practiced without some of the specific details. In particular embodiments, well-known structures and techniques have not been shown in detail in order not to obscure the understanding of the description.

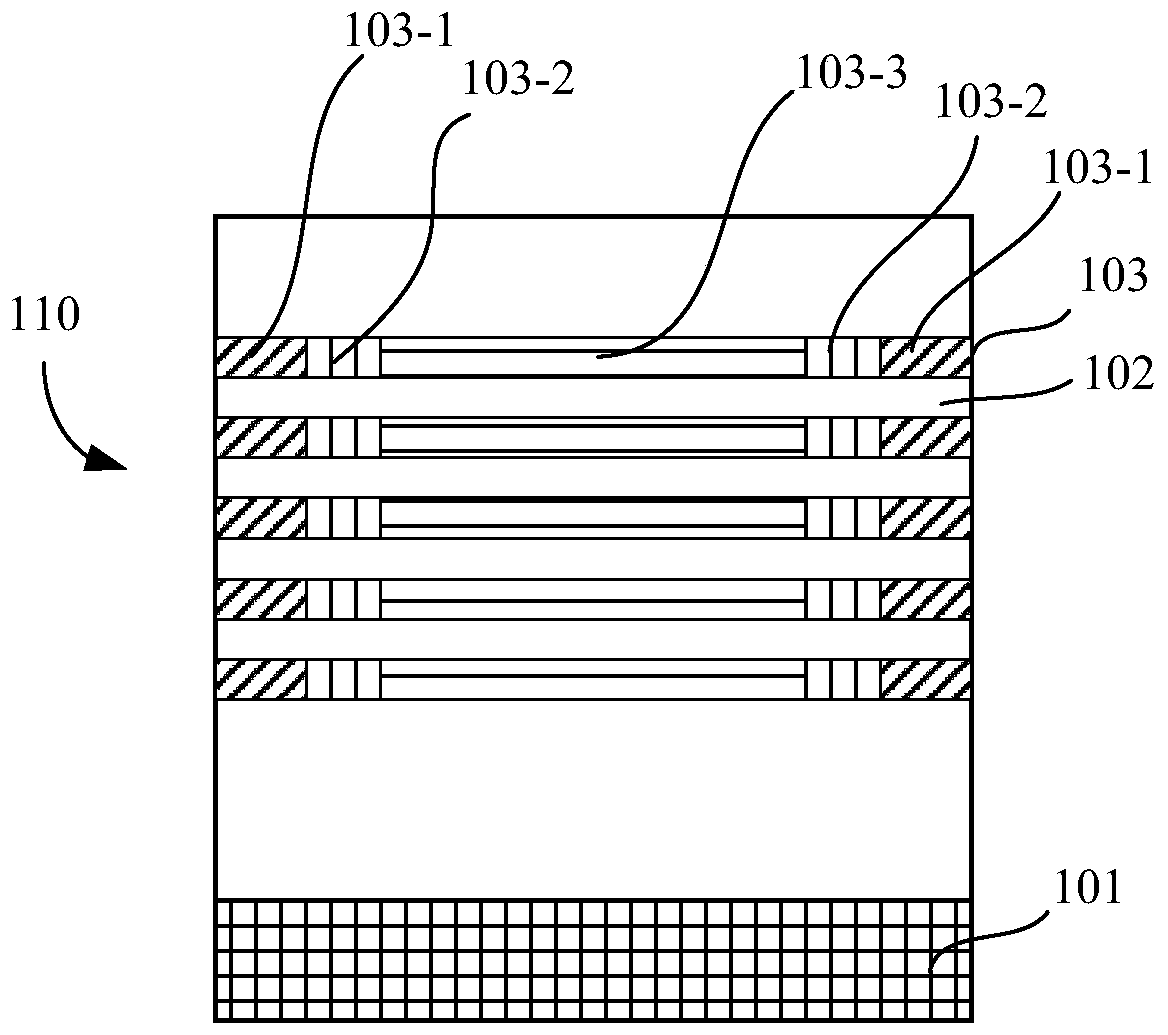

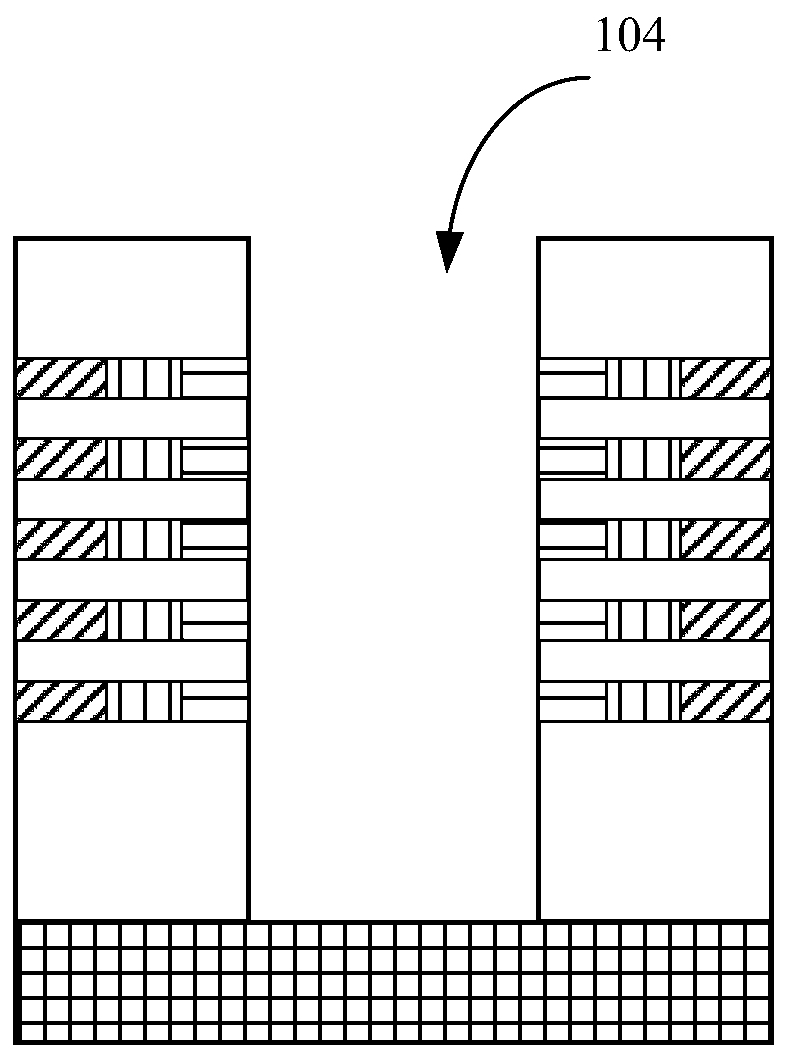

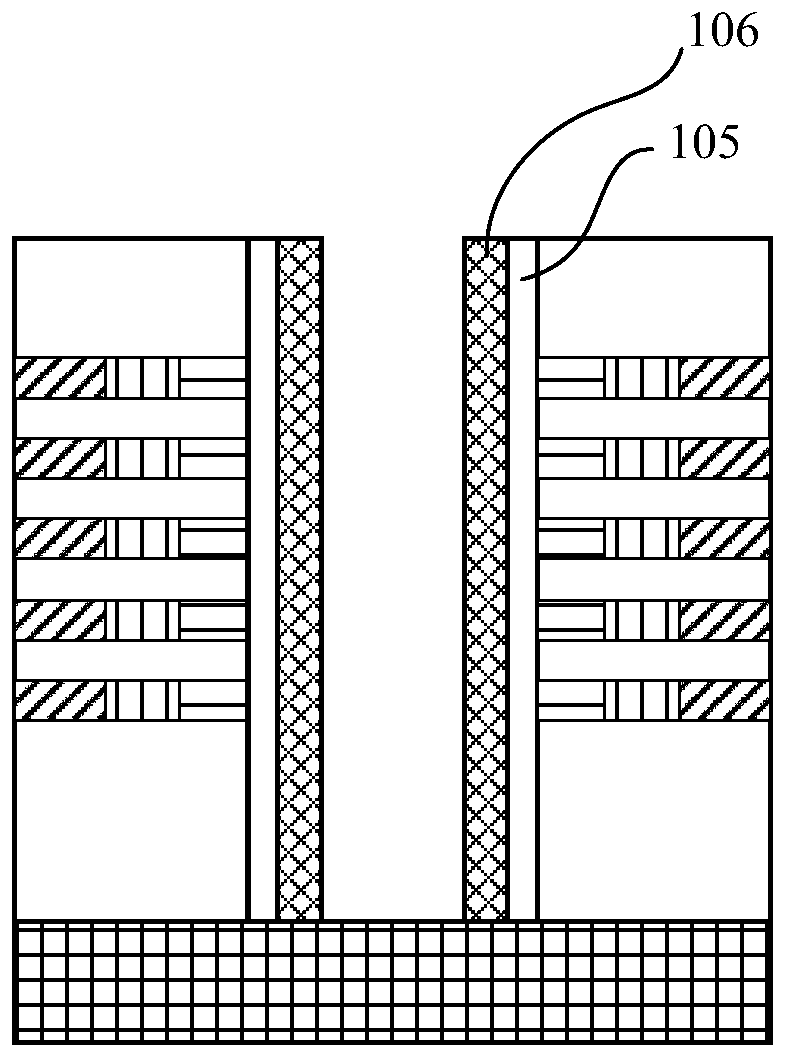

[0019] Figure 1A-Figure 1D A cross-sectional view of an exemplary 3D NAND memory cell deck is shown.

[0020] see Figure 1A , forming a stack structure 110 on the substrate 101 , the stack structure 110 includes insulating material layers 102 and conductive material layers 103 arranged alternately. The conductive material layer 103 is used as a word line. Although only five word lines are shown in the figure, in actual use, the number of word lines may be more or less. In an embodiment, the stack structure 110 may be an OPOP (Oxide / Polysilicon / Oxide / Polysilicon) structure, or an ONON (Oxide / Nitride / Oxide / Nitride) structure, or other structures wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com