Injection mold for flange of large rubber strip

An injection mold and terminal connection technology, which is applied in the field of injection molds for sealing corners with large rubber strips, can solve problems such as high cost, low efficiency, and harmful to employees' health, and achieve the effects of avoiding high costs, reducing costs, and eliminating harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

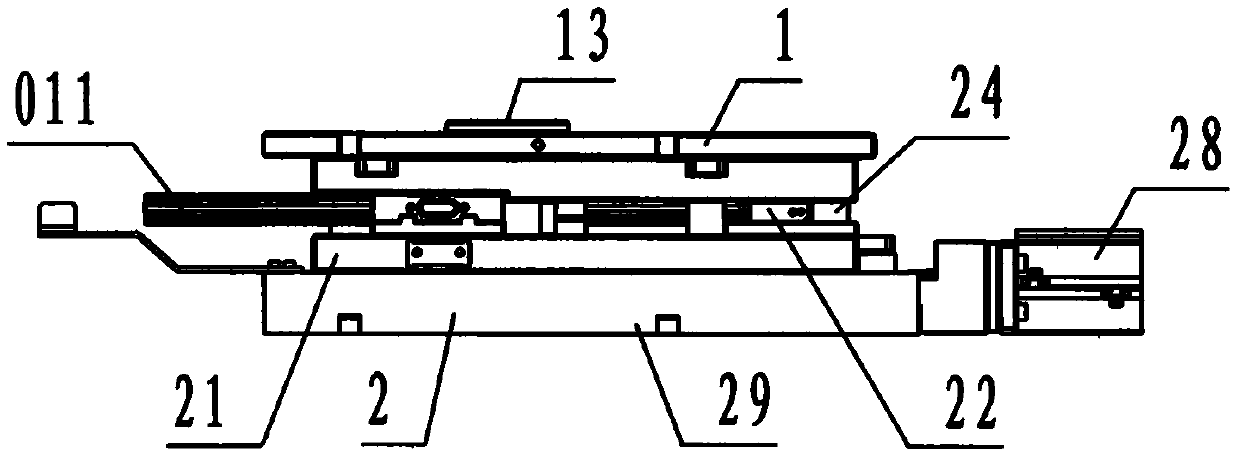

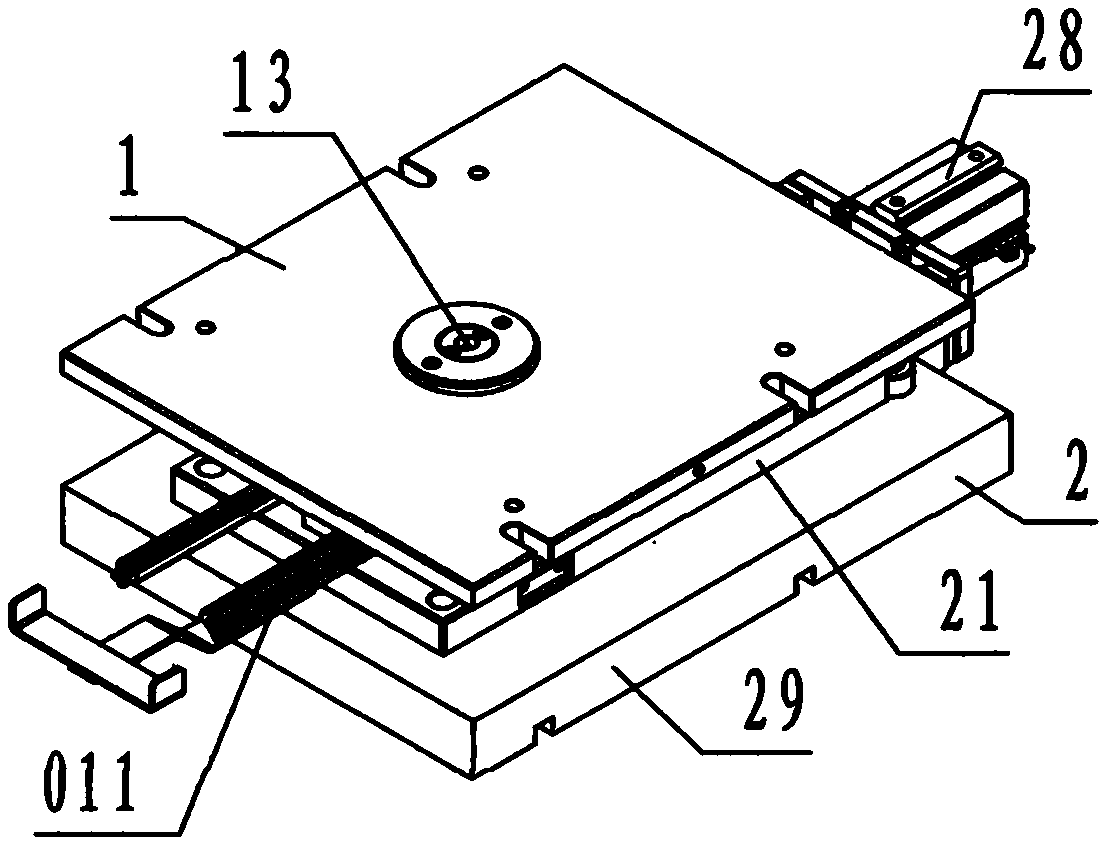

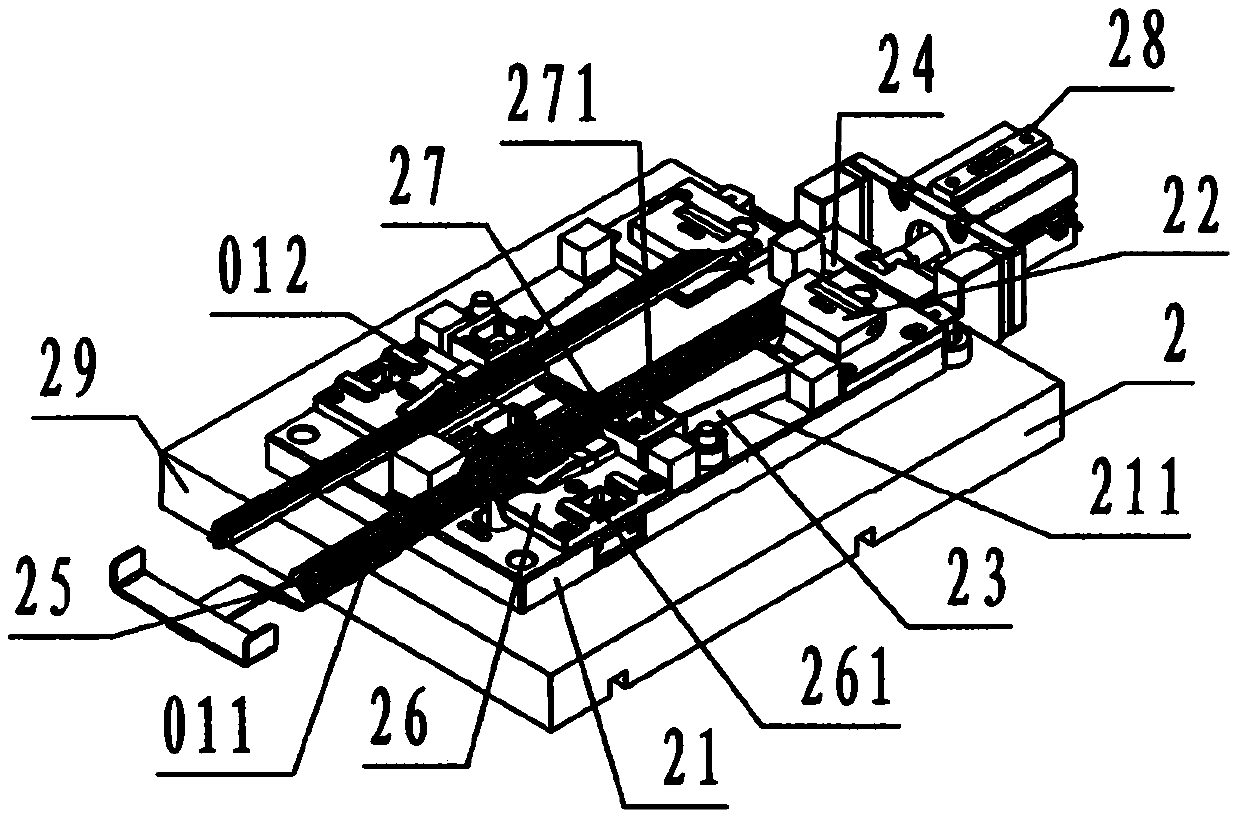

[0040] refer to Figure 1 to Figure 8 , a kind of injection mold of the present invention for sealing the end of a large rubber strip, comprising an upper mold 1 and a lower mold 2, wherein: the upper mold 1 is a rectangular plate-shaped steel member, and the upper mold 1 is provided with a gate 13 The bottom of the upper mold 1 is provided with a shape surface corresponding to the shape surface of the sealing end angle 012, which is called the upper cavity 14; the lower surface of the upper mold 1 is protruded with a C wedge 11 with a small head downward and a truncated pyramid. and D wedge 12;

[0041] The lower mold 2 is composed of a carrier plate 21, an end positioning block 22, a connecting rod 23, a cross bar 24, a blank core 25, a side slider 26, a spring, an end slider 27, an oil cylinder 28 and a base plate 29. The lower mold 2 The center line in the left and right directions is the symmetry line on the top, and there are two symmetrically connected large rubber str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com