Three-dimensional (3D) printing head control system based on field programmable gate array (FPGA)

A control system and print head technology, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve problems such as high timing and synchronization requirements, printing data loss, and asynchrony, etc., to achieve rich functions , simple wiring and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

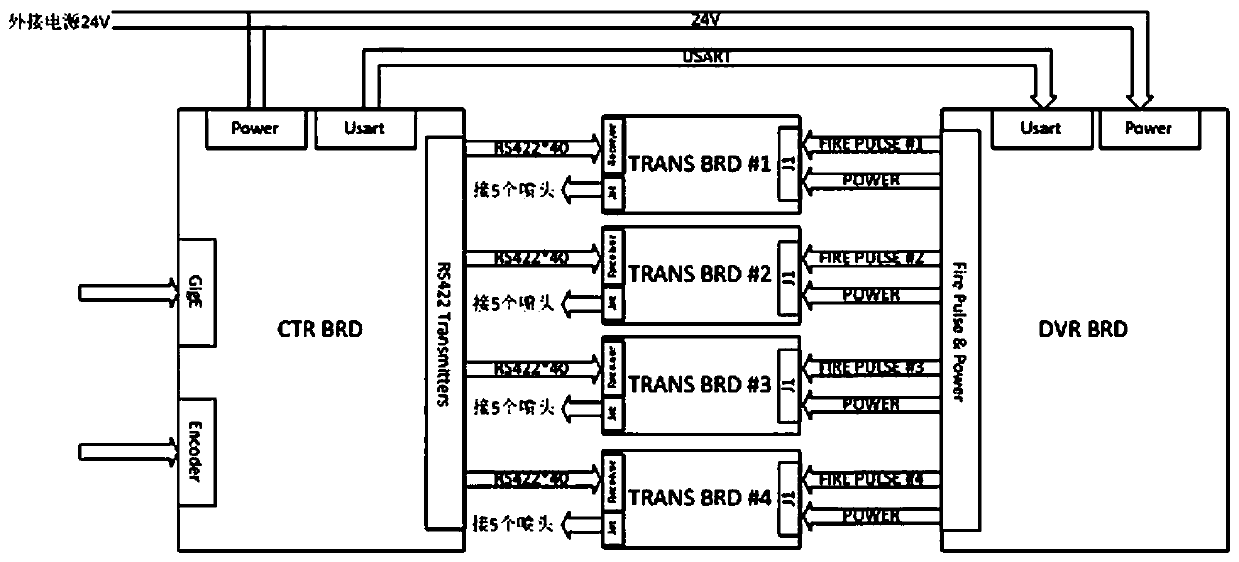

[0035] Such as Figure 1-16 As shown, the FPGA-based 3D print head control system of the present invention is characterized in that it includes a control board for controlling the print head and interacting with external equipment, four adapter boards connected with the control board, and the control board The drive board connected with the board, the drive board is connected with the four adapter boards,

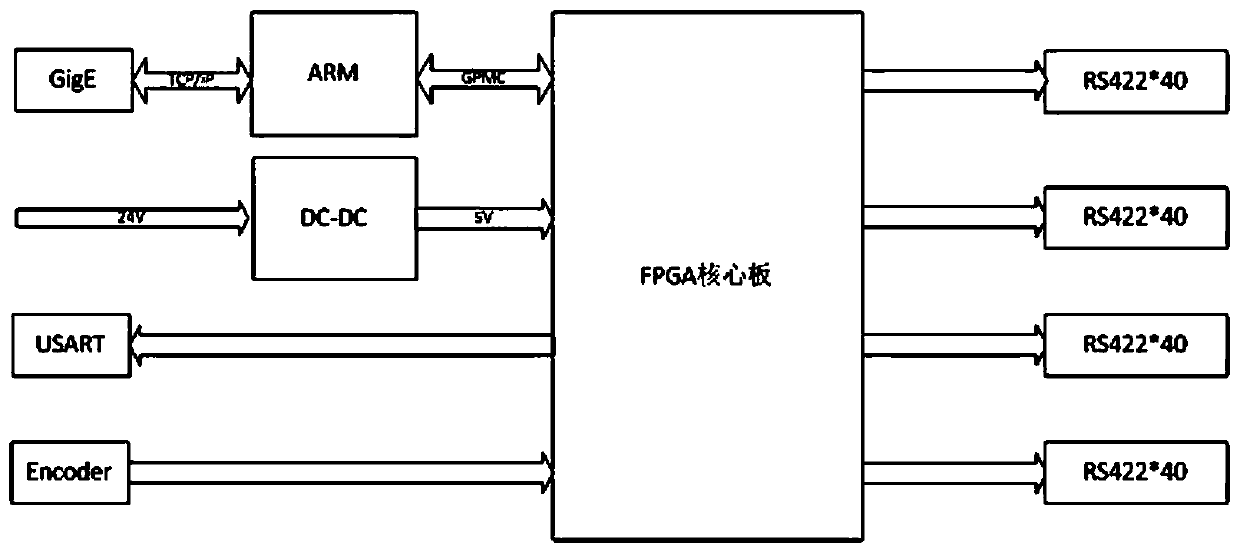

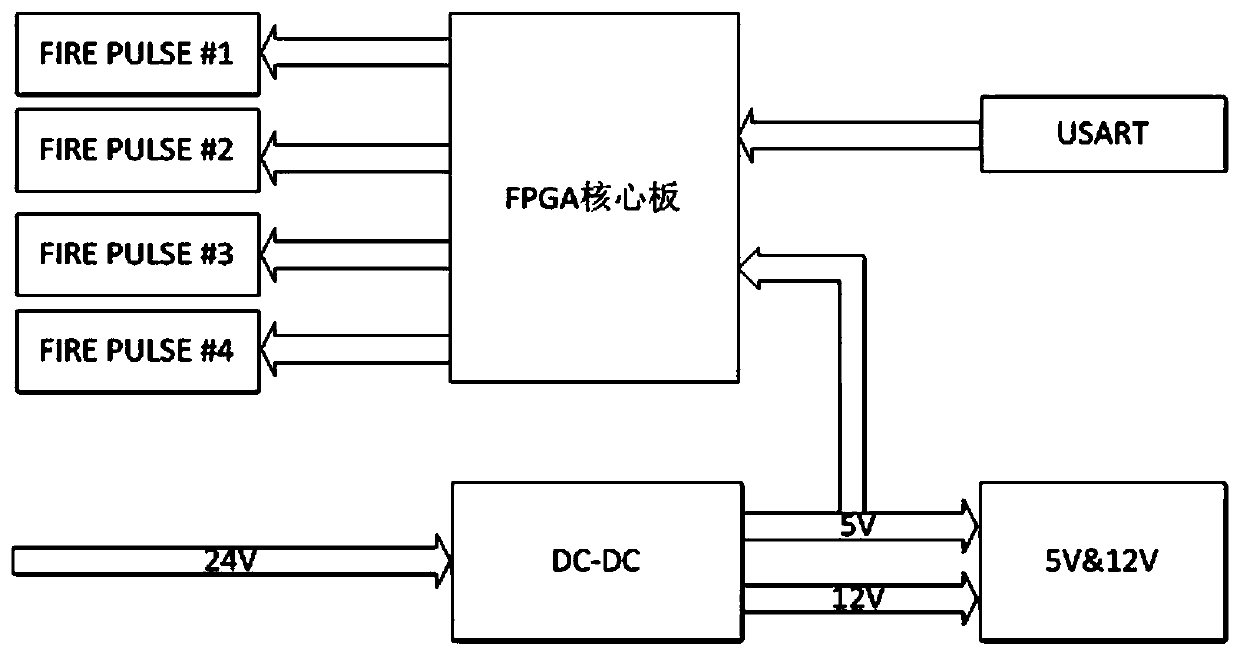

[0036] The control board includes a microprocessor unit FPGA core board I for data interaction and ignition control, an ARM control unit communicating with the microprocessor unit FPGA core board I through a GPMC interface, and the microprocessor unit FPGA The core board I is connected to the DC-DC power conversion, the grating encoder interface, the print data output interface and the four-way RS422 transmitting circuit connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com