Heteroatom-doped polymer nano microsphere which can be produced in large quantity and has cavity structure and preparation method thereof

A technology of structural polymers and nano-microspheres, which is applied in the field of heteroatom-doped polymer nano-microspheres with a cavity structure and its preparation, which can solve the problems of difficult to achieve large-scale industrial applications, long reaction time, and high reaction temperature and other problems to achieve the effect of avoiding the process of template method, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

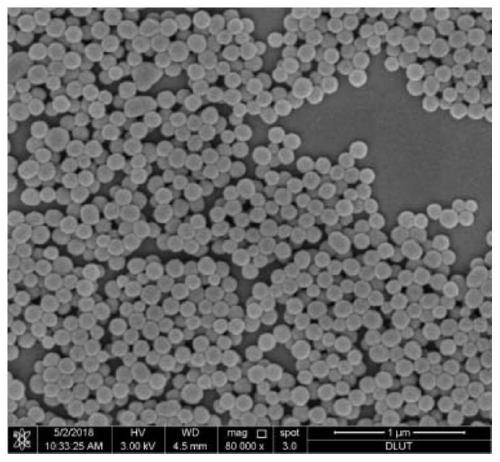

[0064] Dissolve 0.063g (0.0005mol) melamine, 0.054g (0.0005mol) m-phenylenediamine, 0.047g (0.0003mol) 3,5-diaminobenzoic acid in 50mL water, add dropwise 0.2mL ammonia water, temperature 25°C, 500rpm Stir at a rotating speed until the solution turns into a brown suspension. Add 2mL formaldehyde solution, after about 40sec., the liquid turns from clear to cloudy. Keep the temperature and stir at 500rpm for 2h. After the reaction is completed, it is centrifuged, washed with 20% ethanol solution, dried, and observed with an electron microscope to obtain nitrogen-containing polymer nanospheres with a nitrogen content of about 30%. Particle size 116nm as figure 1 shown.

Embodiment 2

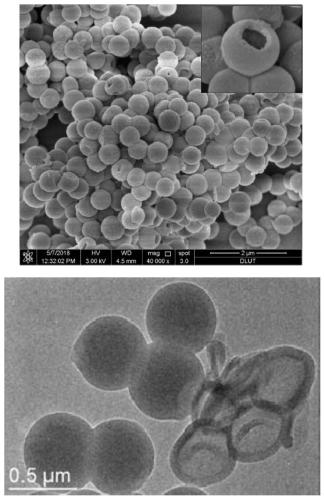

[0066] Dissolve 0.126g (0.001mol) melamine, 0.108g (0.001mol) m-phenylenediamine, 0.047g (0.0003mol) 3,5-diaminobenzoic acid in 50mL acetone, add 0.2mL ammonia water dropwise, at 25°C, Stir at a stirring speed of 500 rpm until the solution becomes a brown suspension. Add 2mL aqueous formaldehyde solution, after about 3 sec., the liquid turns from clear to cloudy. Keep the temperature and stir at 500rpm for 2h. After the reaction is completed, it is centrifuged, washed with 20% ethanol solution, dried, and observed with an electron microscope to obtain nitrogen-containing polymer nanospheres with a nitrogen content of about 40%. Particle size 547nm as figure 2 shown.

Embodiment 3

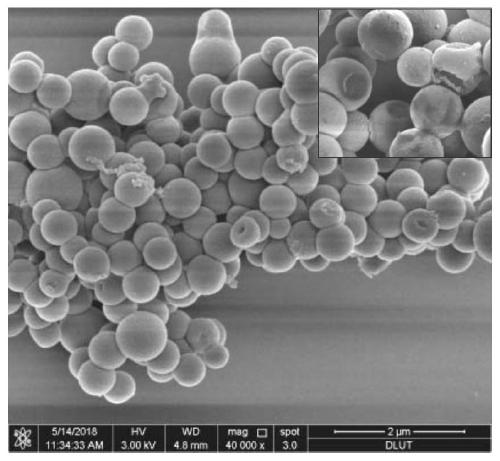

[0068] Dissolve 0.126g (0.001mol) melamine, (0.001mol) m-phenylenediamine, 0.047g (0.0003mol) 3,5-diaminobenzoic acid in 50mL acetone, add ammonia water dropwise, temperature 25°C, stirring speed 500rpm Stir until the solution turns into a brown suspension. Add 2mL formaldehyde solution, after about 7sec., the liquid turns from clear to cloudy. Keep the temperature and stir at 500rpm for 2h. After the reaction is completed, it is centrifuged, washed with 20% ethanol solution, dried, and observed with an electron microscope to obtain nitrogen-containing polymer nanospheres with a nitrogen content of about 40%. Change the amount of ammonia water (0.4mL), as shown in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap