Method for mobile power generation system

A power generation system and generator technology, applied in mobile frames, engine frames, earthwork drilling, etc., can solve problems such as short fracturing operation cycle, and achieve the effect of quick installation and docking, and flexible adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A mobile power generation system, including air intake transportation device 200, exhaust gas transportation device 100 and power generation transportation device 300; power generation transportation device 300, including gas turbine 309, intake chamber 310, exhaust gas collector 308, generator 307, power unit 305, the control system 306 and the first means of transport;

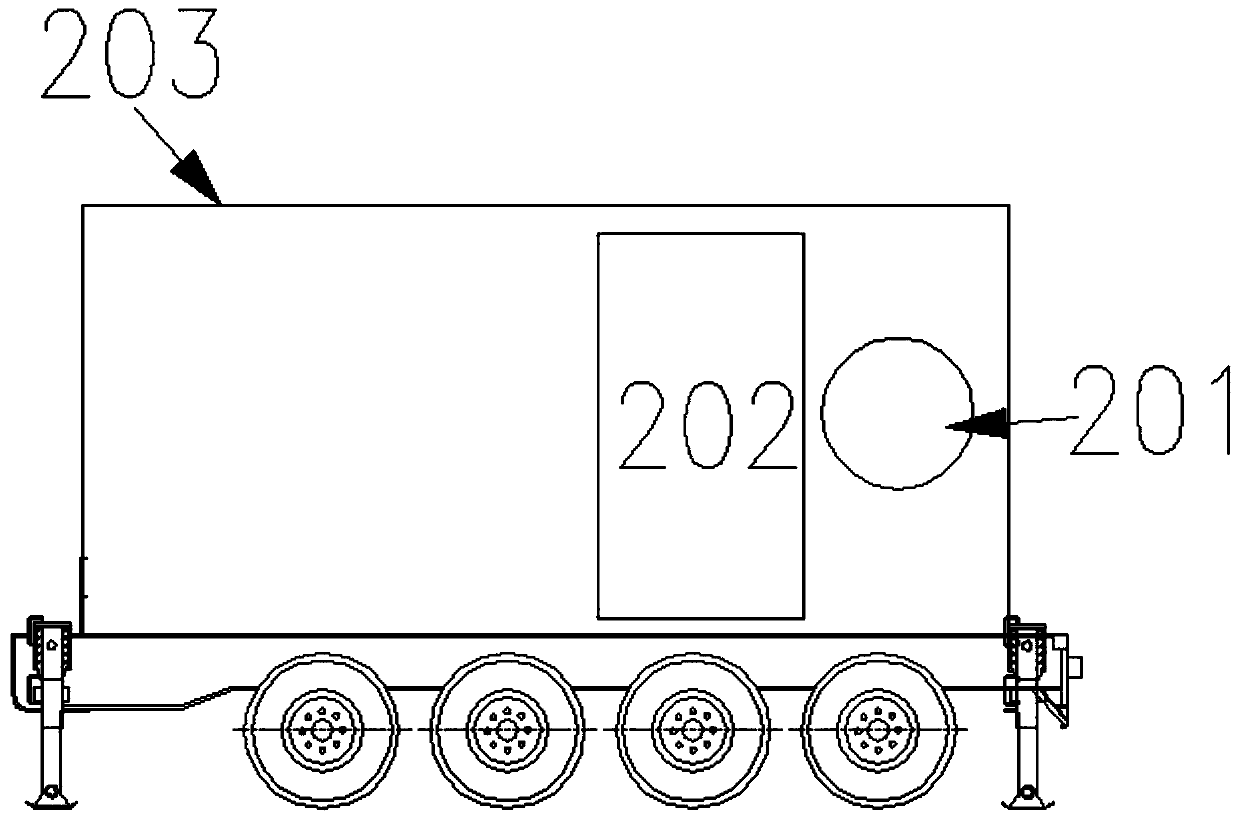

[0032] The air intake transportation device 200 includes an air intake assembly 203 and a second transportation means, the air intake assembly 203 is used to provide combustion air and ventilation air for the combustion engine room;

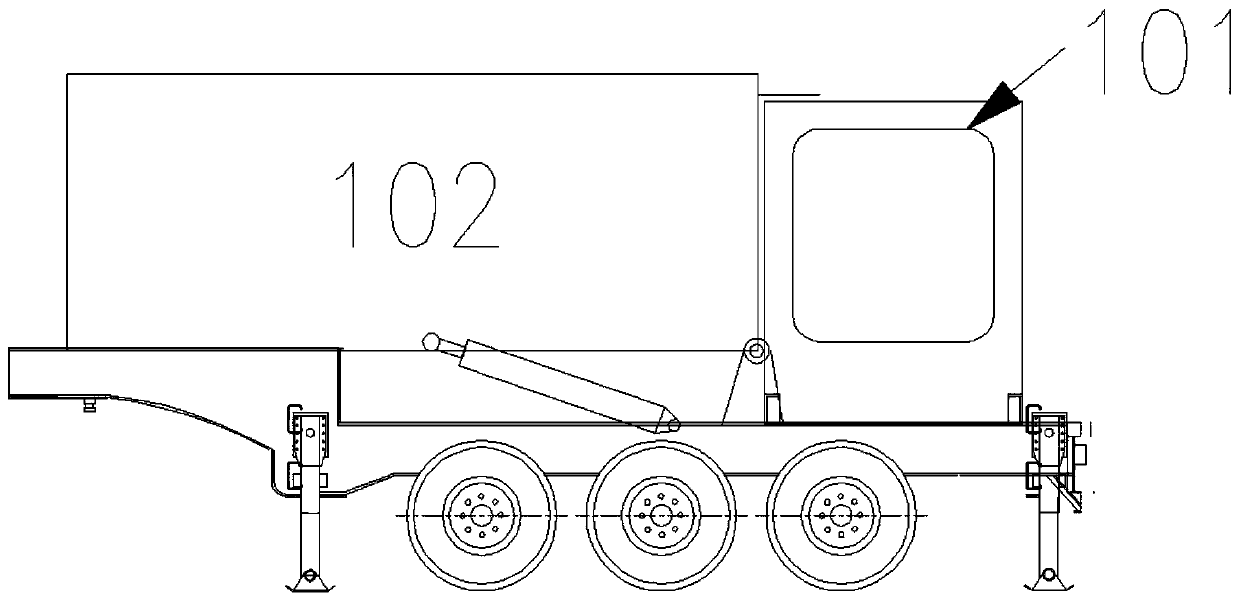

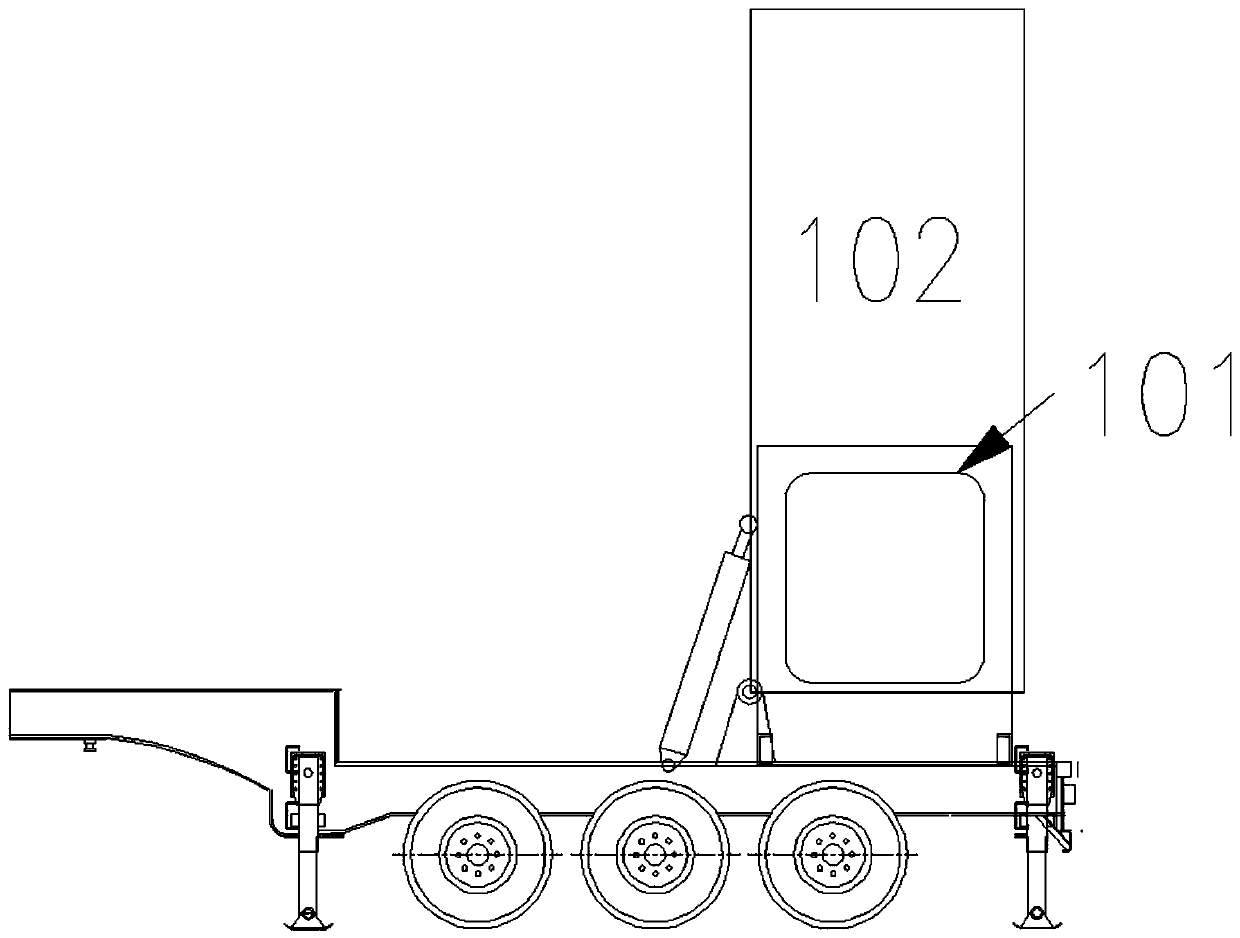

[0033] The exhaust transport device 100 includes an exhaust pipe 102 and a third transport means; the intake transport device 200 and the exhaust transport device 100 are connected to the side of the power generation transport device 300 . Utilize abundant and cheap hydrocarbon fuels (such as natural gas) at the oil and gas well site to provide fuel for the gas turbine 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com