A system and method for monitoring vibration phase of rcp main pump in nuclear power plant

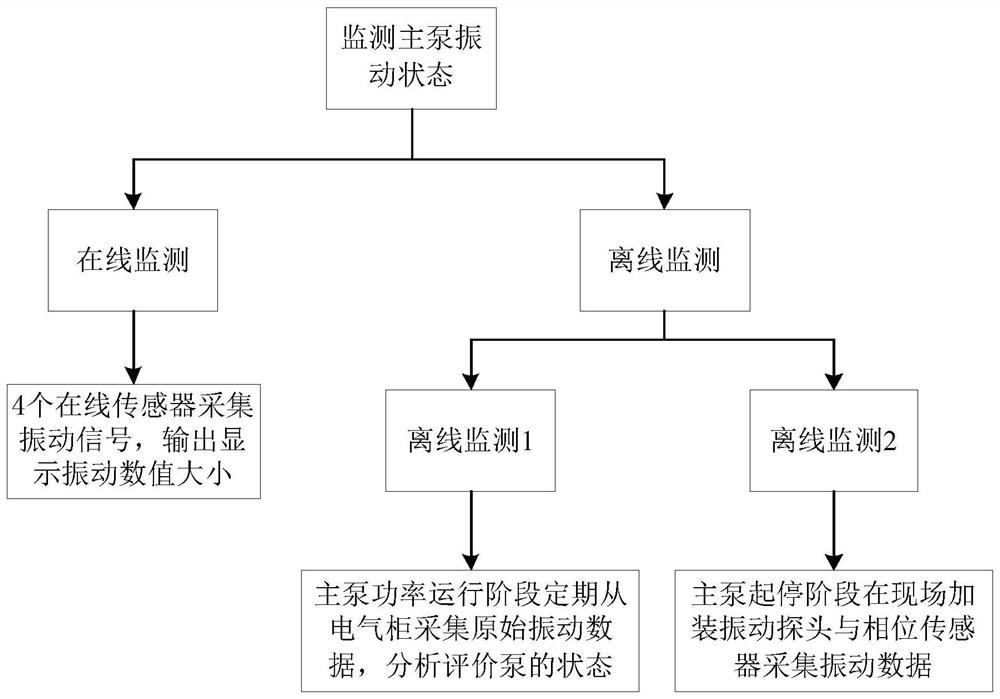

A vibration phase and monitoring system technology, applied in the field of measurement, can solve the problems of inability to monitor the phase online, lack of online analysis and diagnosis basis, etc., to reduce the number of starts and stops and the time of the dynamic balancing window, reduce the occupation of critical paths for downtime and overhaul, and reduce radiation. effect of dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

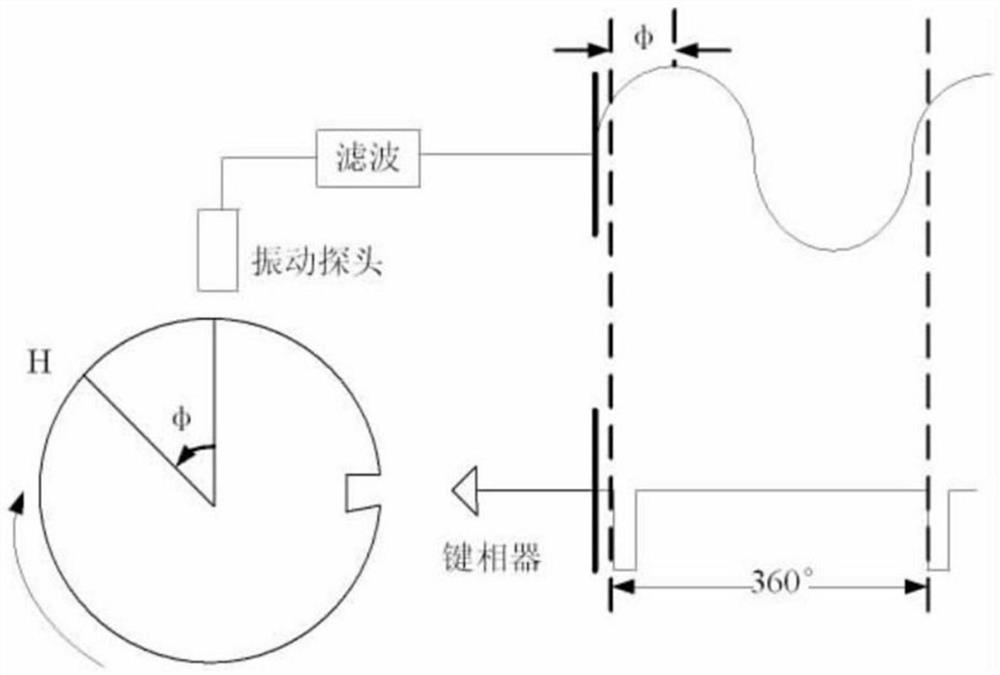

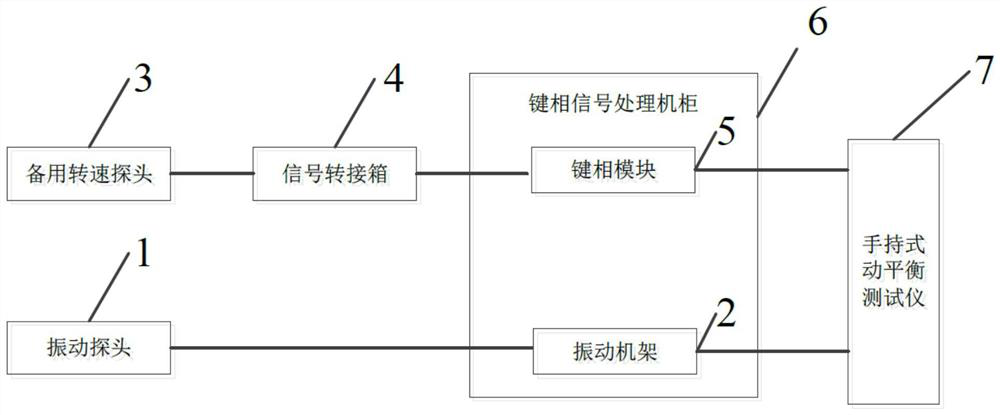

[0043] A nuclear power plant RCP main pump vibration phase monitoring system, such as image 3 As shown, the system includes:

[0044] Vibration probe 1: electrically connected to the vibration frame, used to collect vibration signals on the measured shaft;

[0045] Vibration rack 2: electrically connected to the hand-held dynamic balance tester, used to process the vibration signal collected by the vibration probe;

[0046] Standby rotational speed probe 3: be electrically connected with signal transition box, be used for collecting pulse signal, described pulse signal is the pulse signal that produces when the measured shaft rotates every revolution;

[0047] Signal transfer box 4: electrically connected to the spare speed probe and the key phase module in the key phase signal processing cabinet, used to shunt the pulse signals collected by the spare speed probe and transmit them to the speed signal processing unit and the key phase signal processing cabinet respectively T...

Embodiment 2

[0053] A nuclear power plant RCP main pump vibration phase monitoring system, such as figure 1 As shown, the system includes:

[0054] Vibration probe 1: electrically connected to the vibration frame, used to collect vibration signals on the measured shaft;

[0055] Vibration rack 2: electrically connected to the hand-held dynamic balance tester, used to process the vibration signal collected by the vibration probe;

[0056]Standby rotational speed probe 3: be electrically connected with signal transition box, be used for collecting pulse signal, described pulse signal is the pulse signal that produces when the measured shaft rotates every revolution;

[0057] Signal transfer box 4: electrically connected with the spare speed probe, the key phase signal processing cabinet, and the speed signal processing unit, used to shunt the pulse signals collected by the spare speed probe, and transmit them to the speed signal processing unit and the key phase signal processing cabinet re...

Embodiment 3

[0063] A nuclear power plant RCP main pump vibration phase monitoring system, such as image 3 As shown, the system includes:

[0064] Vibration probe 1: electrically connected to the vibration frame, used to collect vibration signals on the measured shaft;

[0065] Vibration rack 2: electrically connected to the hand-held dynamic balance tester, used to process the vibration signal collected by the vibration probe;

[0066] Standby rotational speed probe 3: be electrically connected with signal transition box, be used for collecting pulse signal, described pulse signal is the pulse signal that produces when the measured shaft rotates every revolution;

[0067] Signal transfer box 4: electrically connected to the spare speed probe, the speed signal processing unit and the key phase module in the key phase signal processing cabinet, used to shunt the pulse signals collected by the spare speed probe and transmit them to the speed signal processing unit and The key phase module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com