Self-excited vibration drilling cutter handle device

A self-excited vibration and drilling tool technology, applied in positioning devices, clamping, support, etc., can solve the problems of workpiece processing quality deterioration, processing system damage, and inability to process qualified parts, so as to improve processing efficiency and improve efficiency , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

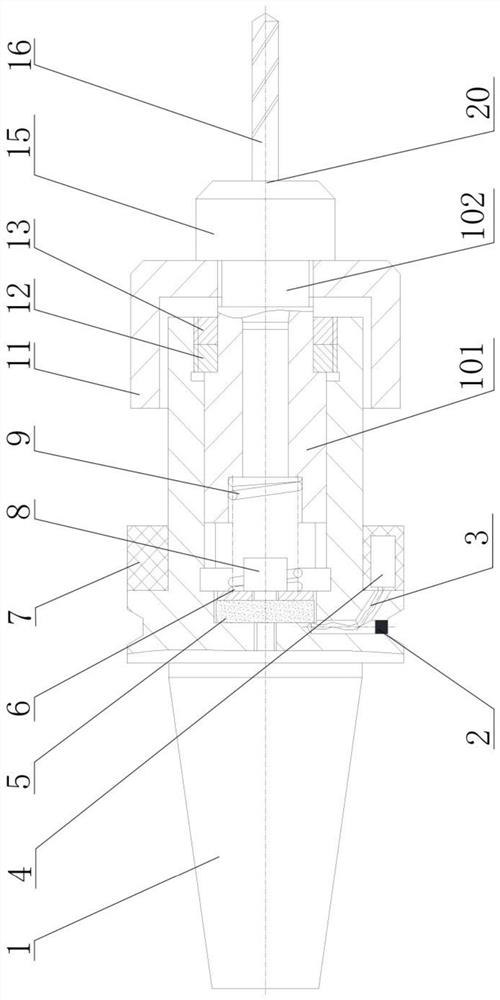

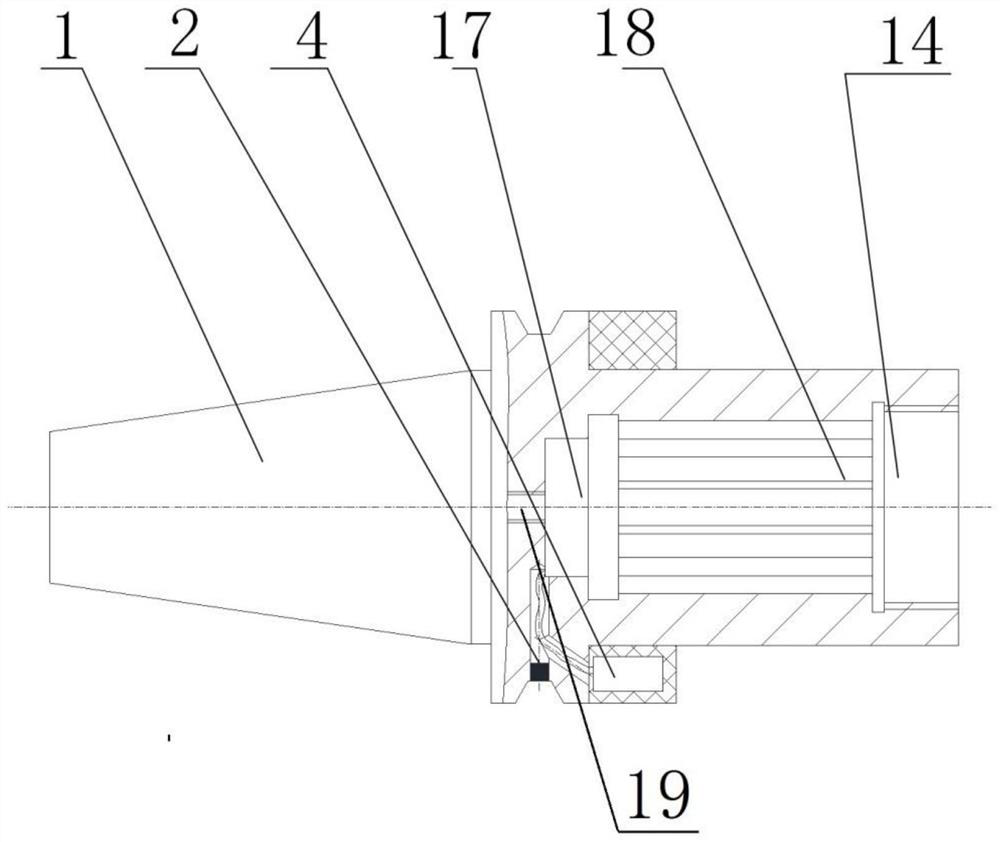

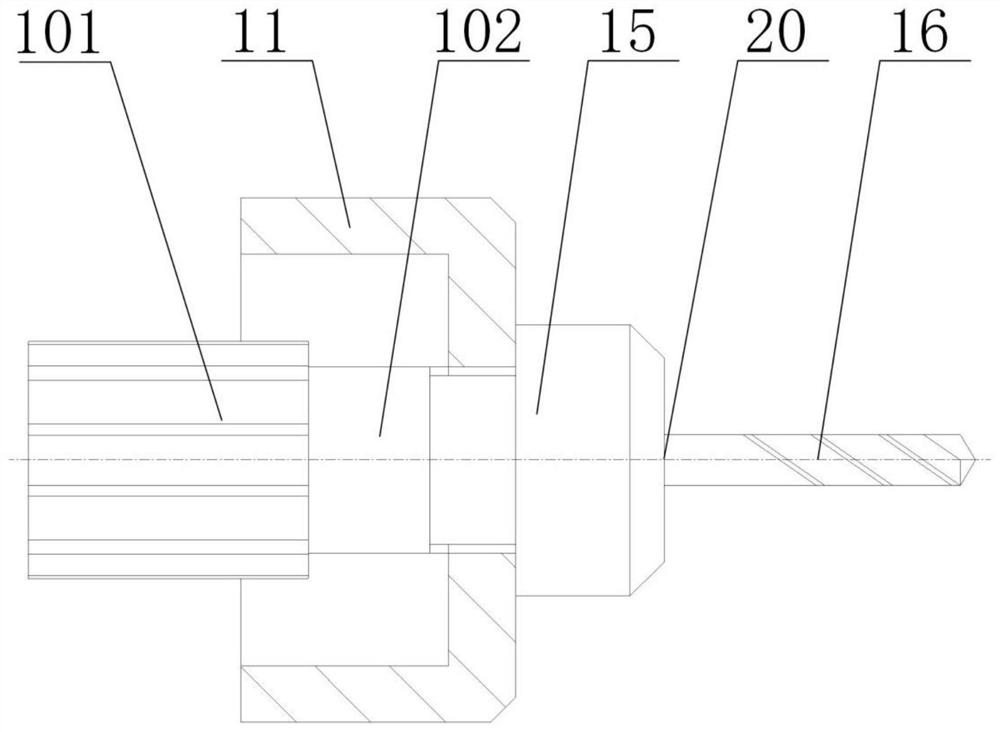

[0033] Such as figure 1 with 3 As shown, a self-excited vibration drilling tool handle device includes a tool handle body 1 and a tool bar. A mounting hole is provided in the tool handle body 1, and the opening of the mounting hole is located at the right end of the tool handle body 1. On the surface, the mounting hole includes a second threaded hole 19, a blind hole 17, a spline hole 18 and a first threaded hole 14 arranged coaxially from left to right, and the second threaded hole 19, blind hole 17, The diameters of the spline hole 18 and the first threaded hole 14 increase sequentially.

[0034] The knife rod is installed in the mounting hole, and the locking screw cover 13 and the adjusting screw cover 12 are installed in the first threaded hole 14; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com