Gas-liquid separation and cooling system

A cooling system, gas-liquid separation technology, applied in liquid fuel engines, pump components, components of pumping devices for elastic fluids, etc., can solve the problem of not very ideal cooling effect, etc. The effect of sufficient time to eliminate potential hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

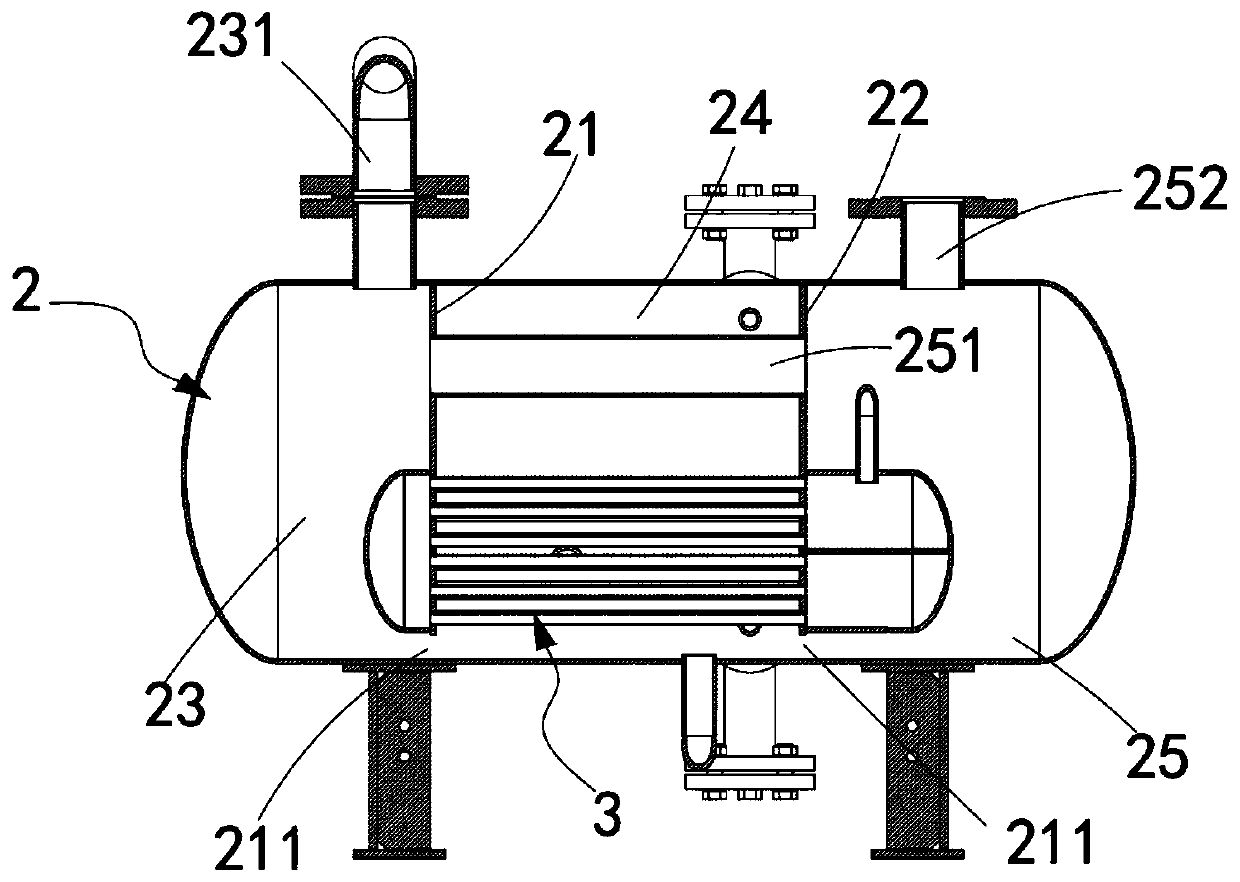

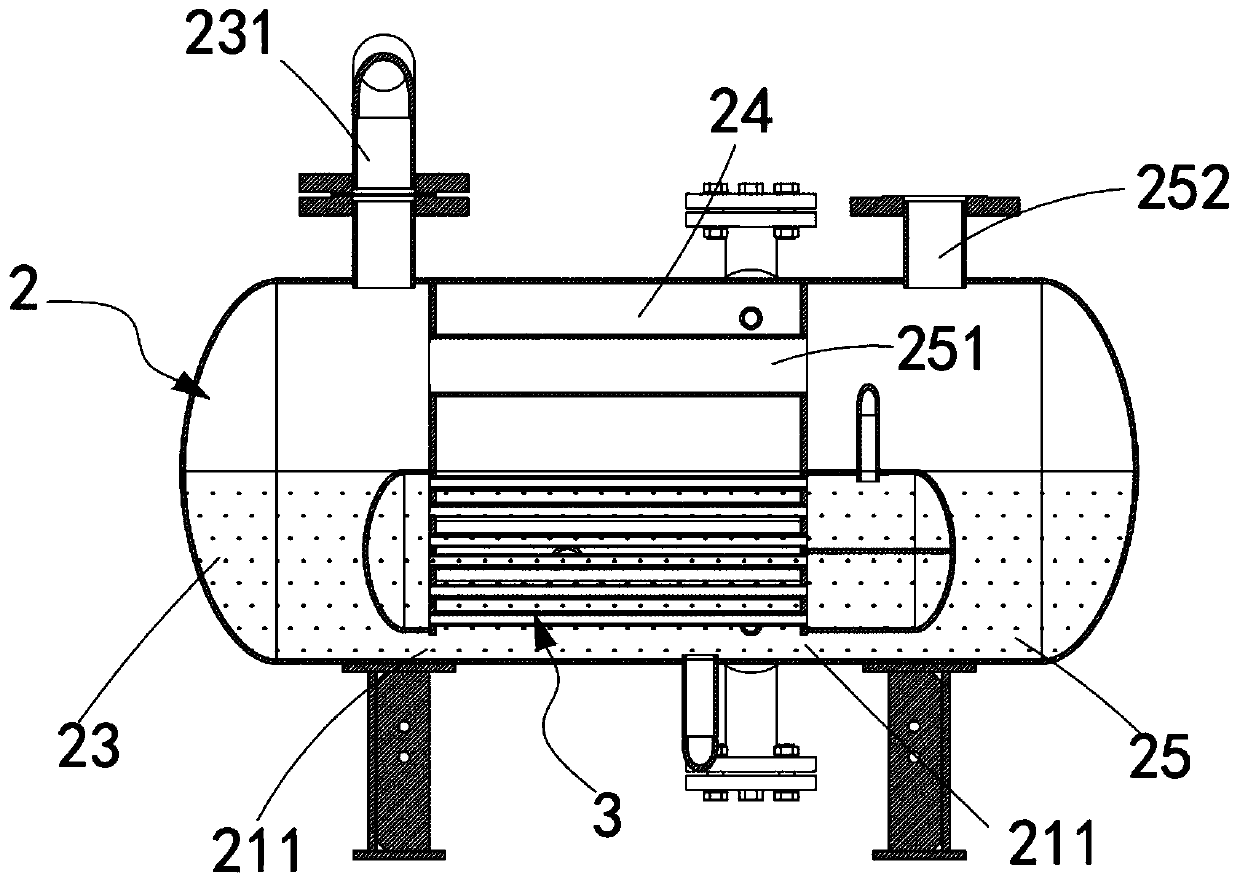

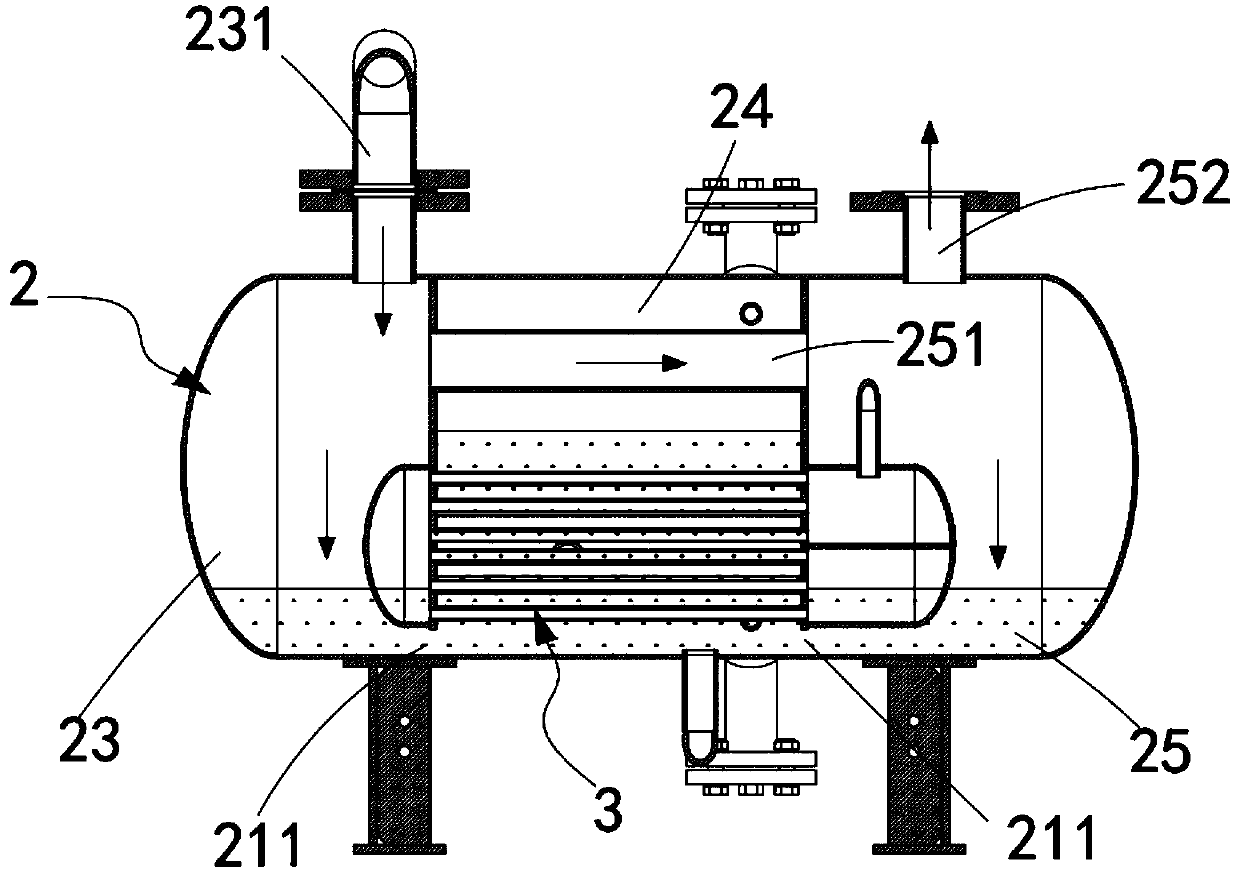

[0047] like figure 1 , Figure 7 to Figure 10 As shown, a gas-liquid separation cooling system includes:

[0048] Gas-liquid separation tank 2, the gas-liquid separation tank 2 is arranged horizontally, and along its horizontal direction, the gas-liquid separation tank 2 is provided with a first liquid level separator 21 and a second liquid level separator 22 to make the gas-liquid separation tank 2 The separation tank 2 is sequentially divided into a first tank compartment 23, a second tank compartment 24 and a third tank compartment 25; and

[0049] a cooler 3, the cooler 3 is arranged inside the gas-liquid separation tank 2 and spans the first tank compartment 23, the second tank compartment 24 and the third tank compartment 25, and It cools the working fluid in the gas-liquid separation tank 2;

[0050] Wherein, the bottoms of the first liquid level separator 21 and the second liquid level separator 22 are both provided with a flow port 211 , through which the first tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com