Metal radiation ceiling board and preparation method thereof

A radiant ceiling and metal technology, applied to the ceiling, heating methods, lighting and heating equipment, etc., can solve the problem of wasting the heat exchange effect of the heat exchange surface of the coil, the poor heat exchange effect of the heat exchange tube, and the unsatisfactory heat exchange effect of the ceiling and other problems, to achieve the effects of easy processing and implementation, reducing poor heat transfer effect, and enhancing energy storage and heat conduction capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

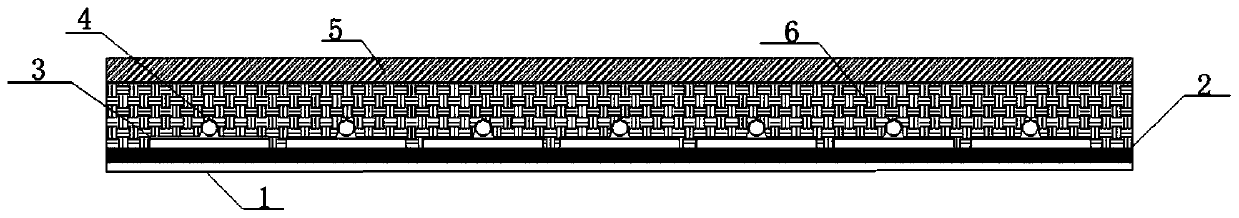

[0035] A metal radiant ceiling panel such as figure 1 As shown, it includes metal gusset 1, sound insulation cotton 2, radiation unit, phase change energy storage material 6 and insulation layer 5 arranged in sequence from bottom to top; the bottom of the radiation unit is placed on the sound insulation cotton 2, and the radiation unit is Variable energy storage material 6 is tightly packed.

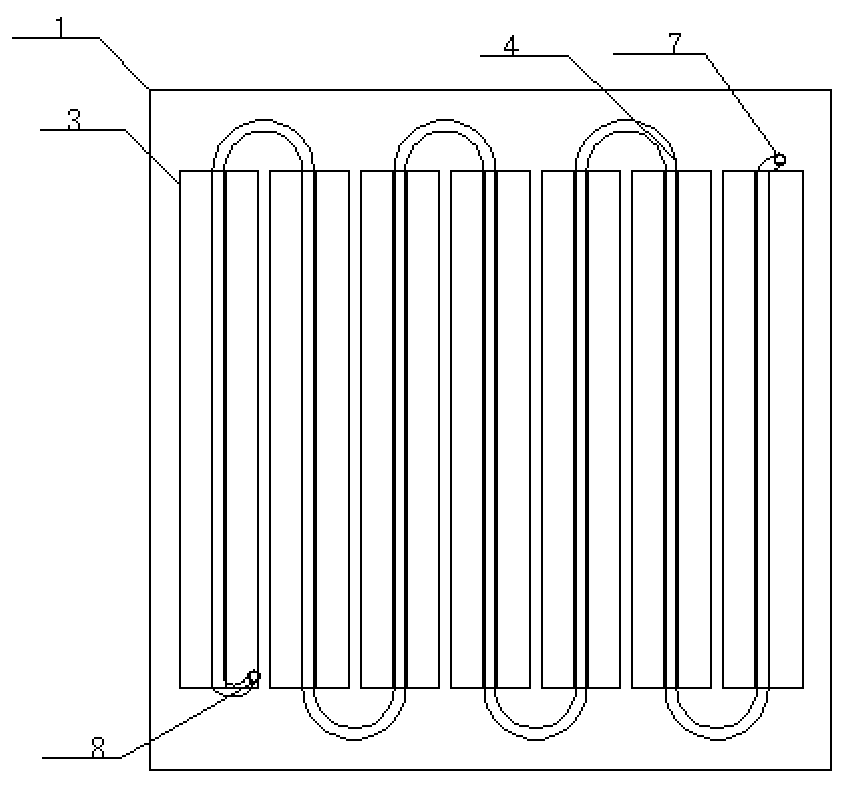

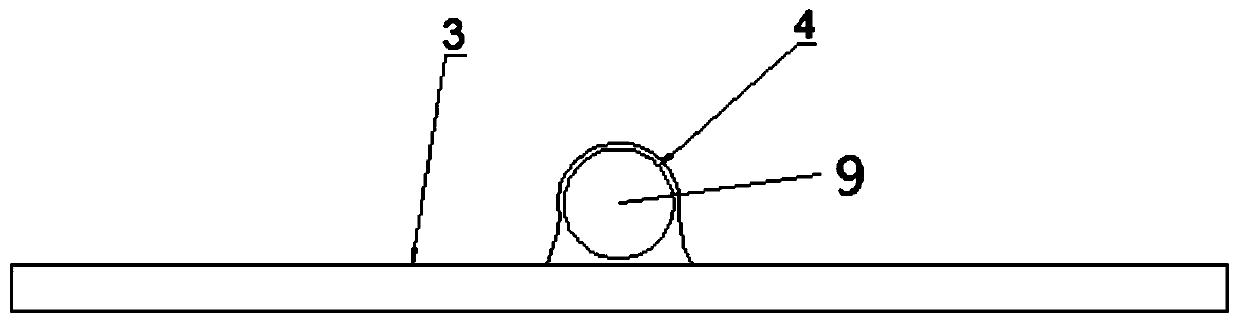

[0036] Among them, such as figure 2 As shown, the radiating unit includes several fins 3 arranged side by side, and there is a gap between two adjacent fins 3; each fin 3 has a through hole 9 along its length, and the fins 3 and the through-holes 9 inside the fins 3 are all arranged in parallel; the through-holes 9 inside the fins 3 are sequentially connected through the connecting pipe 4 to form an S-shaped pipeline, which is a channel for the flow of heat exchange fluid, wherein the through-holes 9 The inner diameter is equal to the inner diameter of the connecting pipe 4; in this e...

Embodiment 2

[0047] A metal radiant ceiling panel such as figure 1 As shown, it includes metal gusset 1, sound insulation cotton 2, radiation unit, phase change energy storage material 6 and insulation layer 5 arranged in sequence from bottom to top; the bottom of the radiation unit is placed on the sound insulation cotton 2, and the radiation unit is Variable energy storage material 6 is tightly packed.

[0048] Among them, such as figure 2As shown, the radiating unit includes several fins 3 arranged side by side, and there is a gap between two adjacent fins 3; each fin 3 has a through hole 9 along its length, and the fins 3 and the through-holes 9 inside the fins 3 are all arranged in parallel; the through-holes 9 inside the fins 3 are sequentially connected through the connecting pipe 4 to form an S-shaped pipe, which is a passage for the heat exchange fluid to circulate, and the inner diameter of the through-hole 9 is The size is equal to the inner diameter of the connecting pipe 4;...

Embodiment 3

[0058] A metal radiant ceiling panel such as figure 1 As shown, it includes metal gusset 1, sound insulation cotton 2, radiation unit, phase change energy storage material 6 and insulation layer 5 arranged in sequence from bottom to top; the bottom of the radiation unit is placed on the sound insulation cotton 2, and the radiation unit is Variable energy storage material 6 is tightly packed.

[0059] Among them, such as figure 2 As shown, the radiation unit includes several fins 3 arranged side by side, and there is a gap between two adjacent fins 3; each fin 3 is provided with a straight tube along its length, and the fins 3 and The through-straight tubes inside the fins 3 are all arranged in parallel; the through-straight tubes inside the fins 3 are sequentially connected through the connecting pipe 4 to form an S-shaped pipeline, which is a channel for the circulation of heat exchange fluid, and the inner diameter of the through-straight tubes is the same as The inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com