Drying system for medicinal material processing

A drying system and a technology for processing medicinal materials, which can be applied to drying solid materials by heating, drying of biomass, drying of solid materials, etc., which can solve the problems of influence on the pharmacological effect of medicinal materials, influence on the quality of medicinal materials, and poor use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

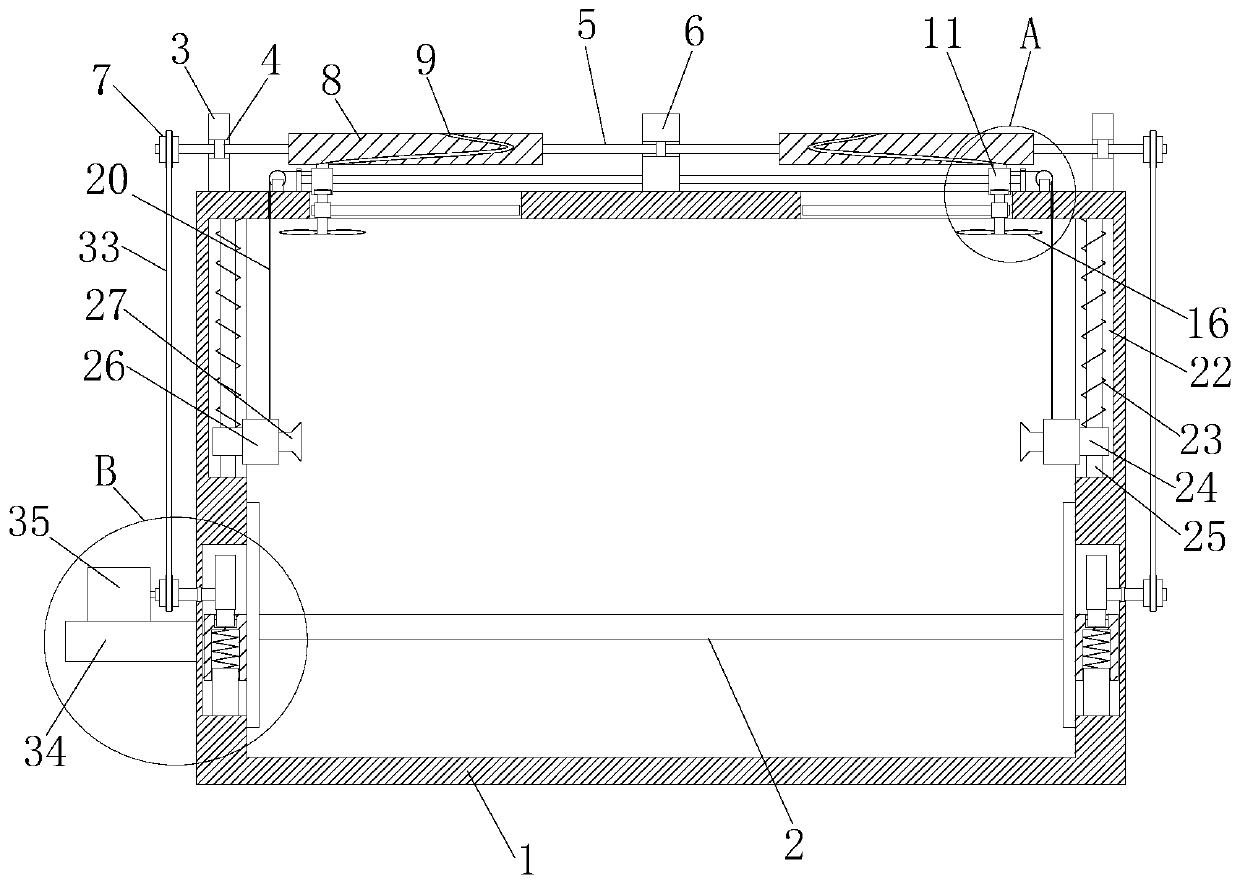

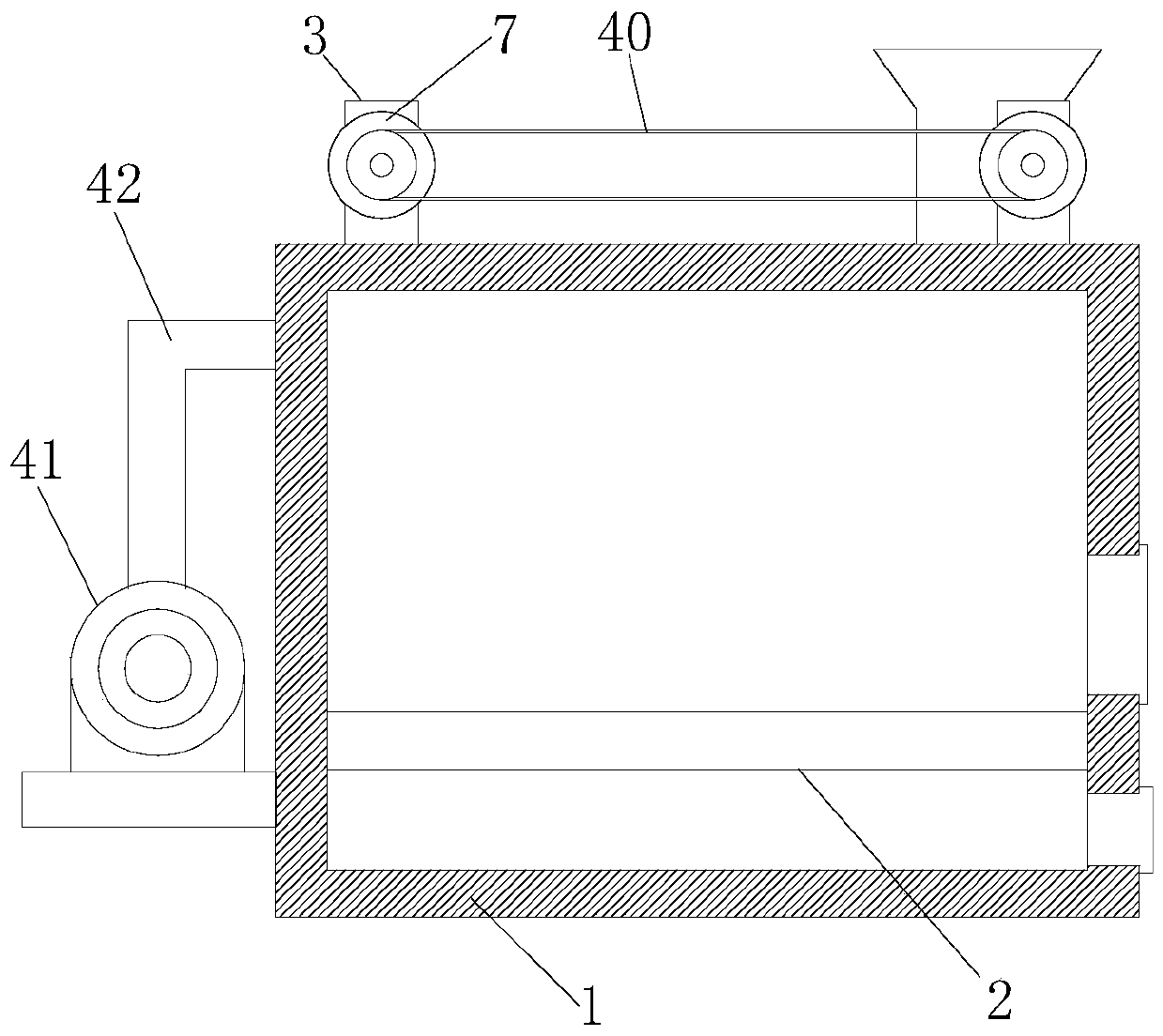

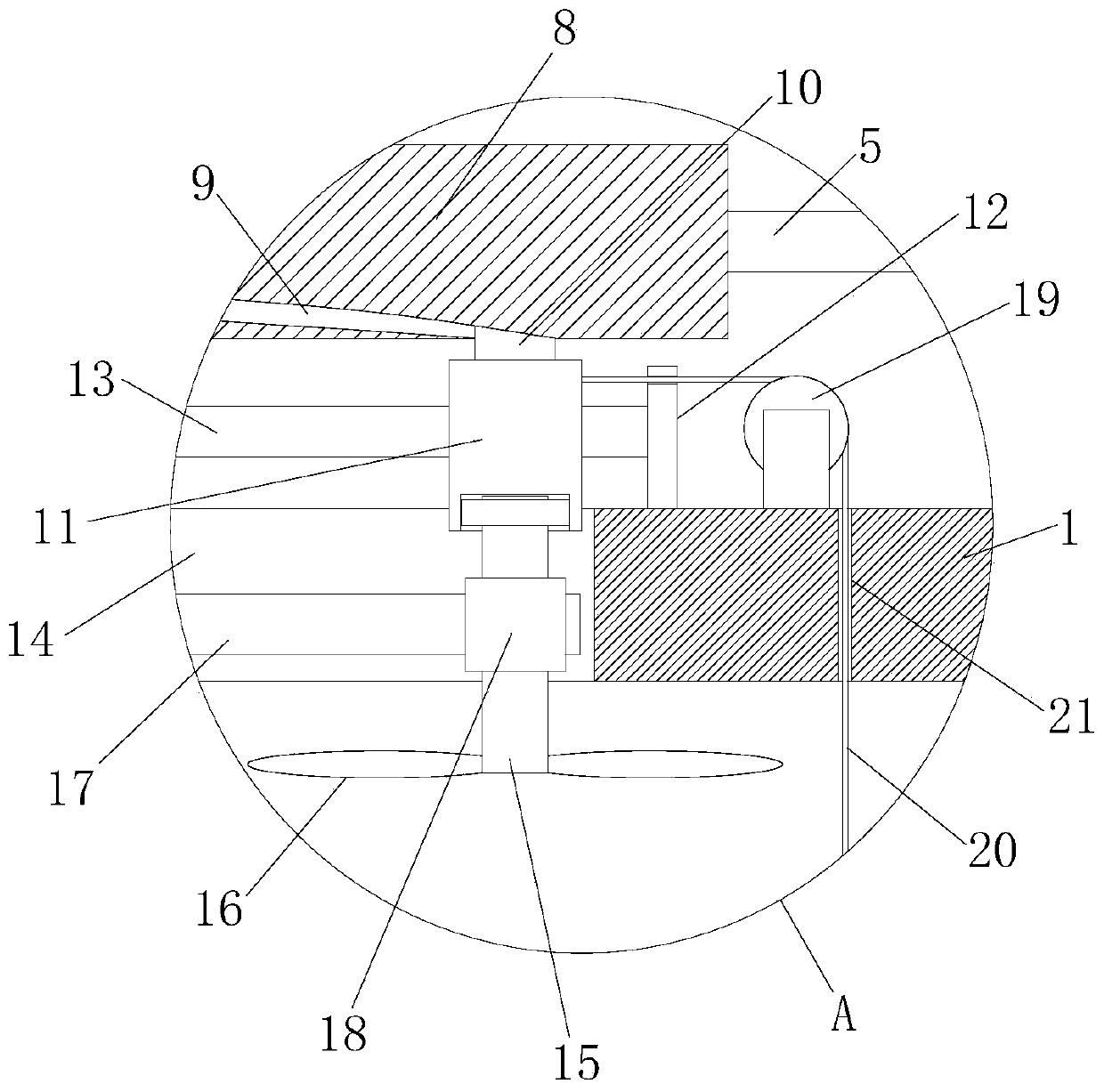

[0028] refer to Figure 1-5, a drying system for processing medicinal materials, comprising a processing box 1, a sieve plate 2 is arranged in the processing box 1, four bearing seats 3 are fixedly installed on both ends of the top of the processing box 1, and bearings are arranged on the four bearing seats 3 Holes 4, two transmission rods 5 are arranged on the top of the processing box 1, and the two ends of the transmission rods 5 are respectively rotated and installed in the corresponding two bearing holes 4, and the top of the processing box 1 is fixedly installed with two fixed seats 6, fixed The seat 6 is provided with a rotation hole, and the transmission rod 5 is rotatably installed in the corresponding rotation hole. Two rotation rollers 8 are fixedly set on the transmission rod 5, and an annular transmission groove 9 is provided on the rotation roller 8. The two transmission rods 5 The first sprockets 7 are fixedly sleeved at both ends of the two ends of the processi...

Embodiment 2

[0039] refer to Figure 1-5 , a drying system for processing medicinal materials, comprising a processing box 1, a sieve plate 2 is arranged in the processing box 1, four bearing seats 3 are fixedly installed on both ends of the top of the processing box 1 by welding, and four bearing seats 3 are provided with There are bearing holes 4, two transmission rods 5 are arranged on the top of the processing box 1, and the two ends of the transmission rods 5 are respectively rotated and installed in the corresponding two bearing holes 4, and the top of the processing box 1 is fixed by welding. Seat 6, the fixed seat 6 is provided with a rotation hole, the transmission rod 5 is rotated and installed in the corresponding rotation hole, the transmission rod 5 is fixedly set with two rotation rollers 8 by welding, and the rotation roller 8 is provided with an annular transmission groove 9 , the two ends of the two transmission rods 5 are all provided with the first sprocket 7 through wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com