Three-dimensional automatic forming method and system for belt conveyor

A belt conveyor, automatic forming technology, applied in the direction of conveyor, transportation and packaging, computer-aided design, etc., can solve the problems of high error rate, low efficiency, high labor cost, etc., and achieve high accuracy, high efficiency, universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

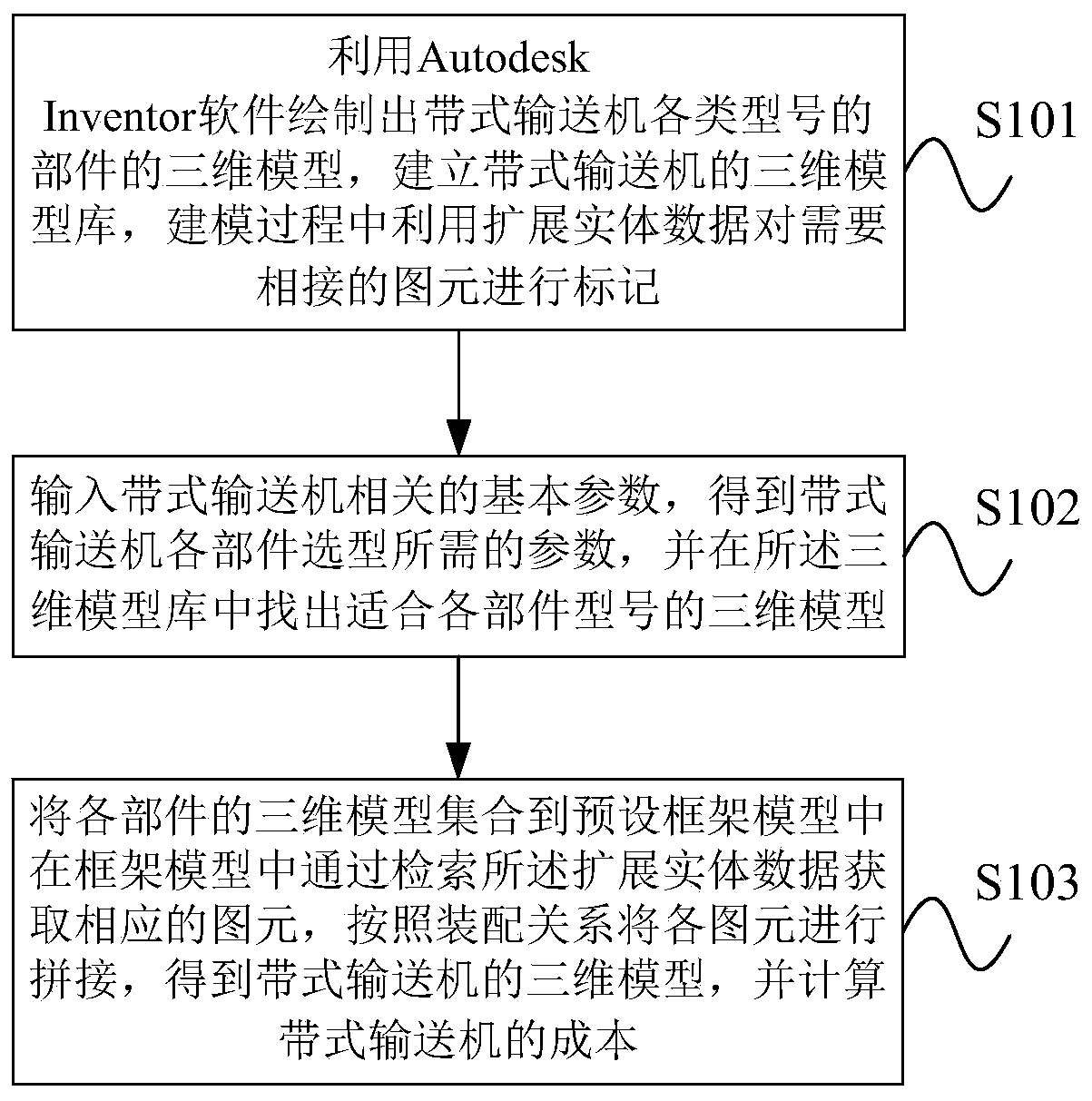

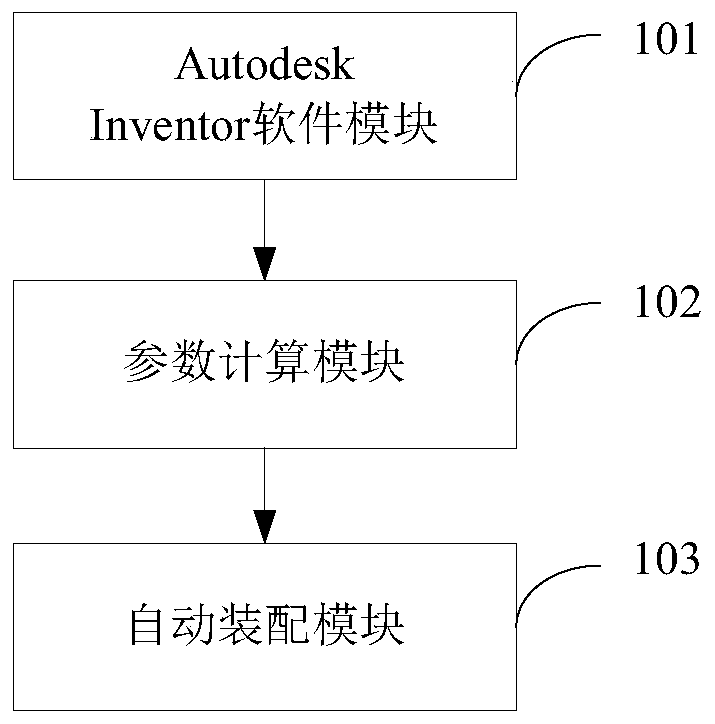

Method used

Image

Examples

Embodiment approach

[0053] As an implementable manner, this step specifically includes:

[0054] Use the extended entity data to match the corresponding graphic element with the position to be assembled in the frame model, and automatically assemble it to the specified position of the frame model;

[0055] After the 3D model of the belt conveyor is generated, the specification parameters and cost data of each component are automatically extracted, and an Excel table is generated, and the cost of the belt conveyor is calculated based on the cost data of each component.

[0056] The cost data of each component refers to the unit price of each component, and the cost of the belt conveyor refers to the sum of the unit prices of all the components it contains, such as Figure 7 shown.

[0057] The method provided by the embodiments of the present invention has great flexibility and strong adaptability, and is applicable to any complicated pattern of the belt conveyor.

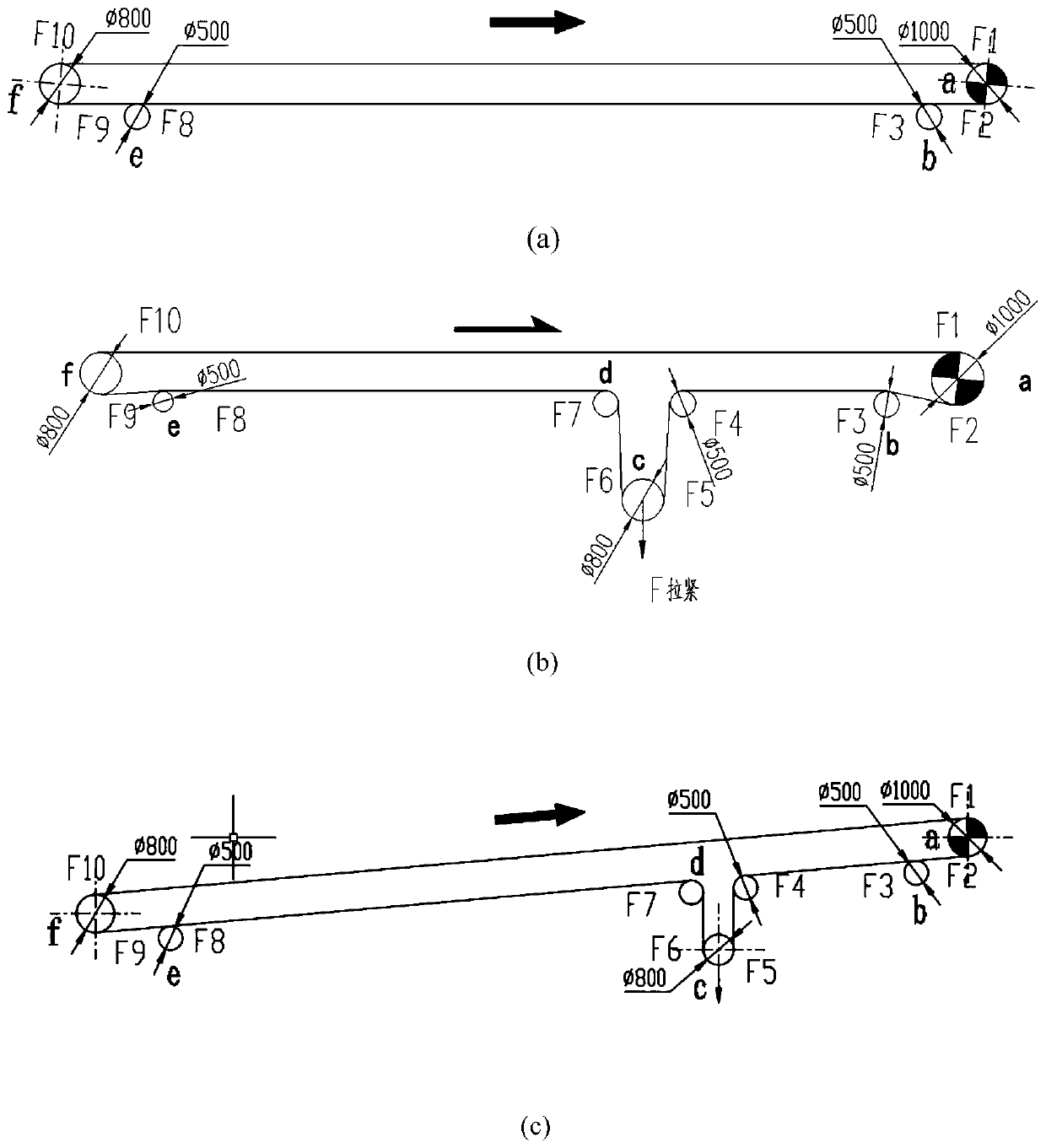

[0058] Such as image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com