Flexible electrode based on conductive polymer and preparation method thereof

A conductive polymer, flexible electrode technology, used in equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc. In order to achieve the effect of good consistency in large area, excellent anti-reflection and anti-reflection performance, self-cleaning performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

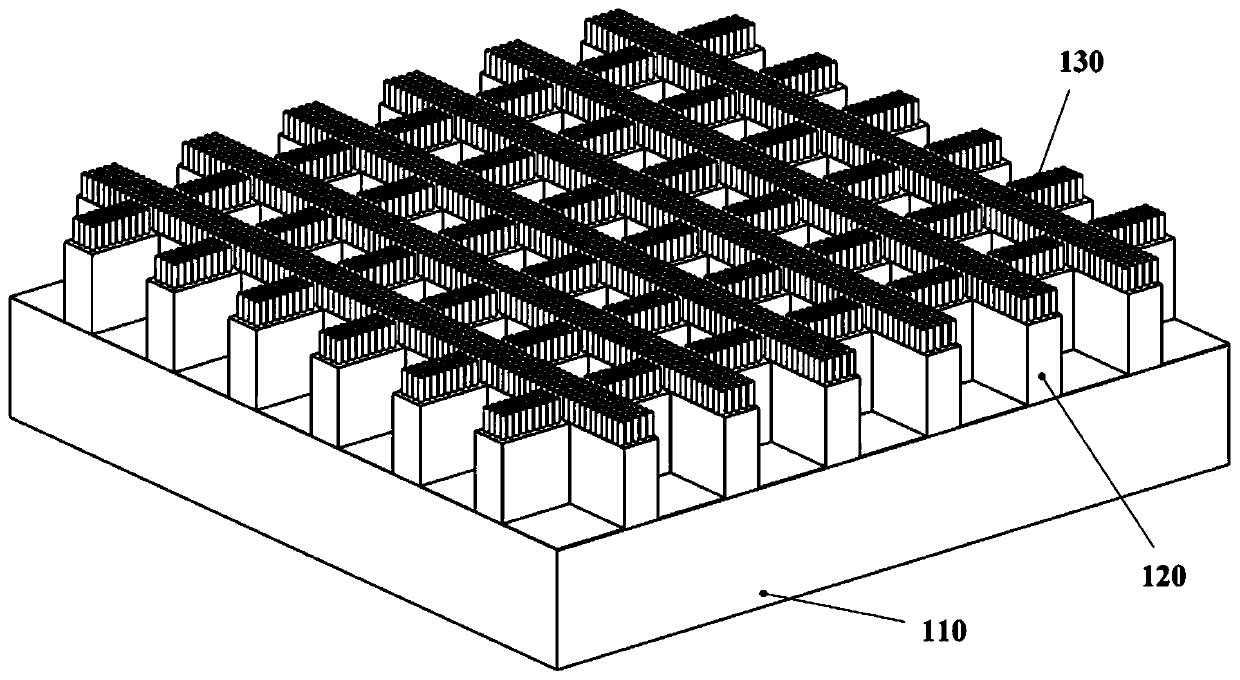

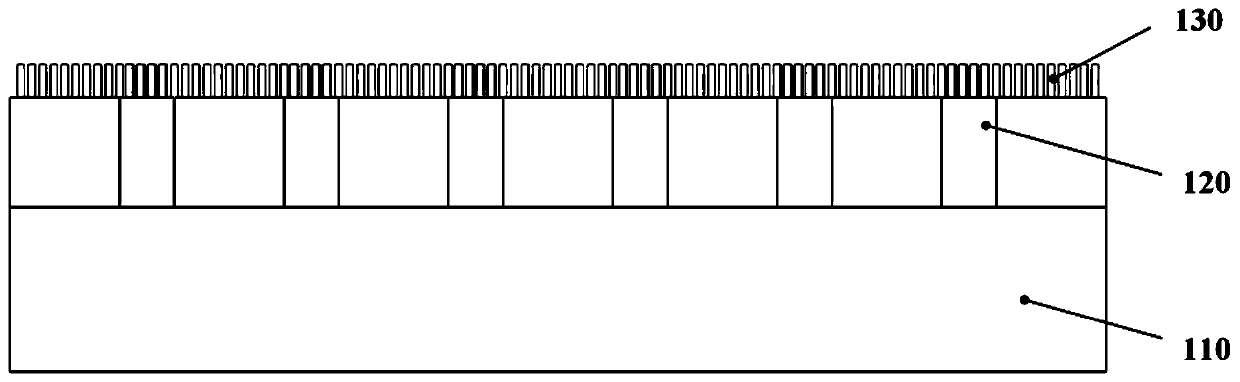

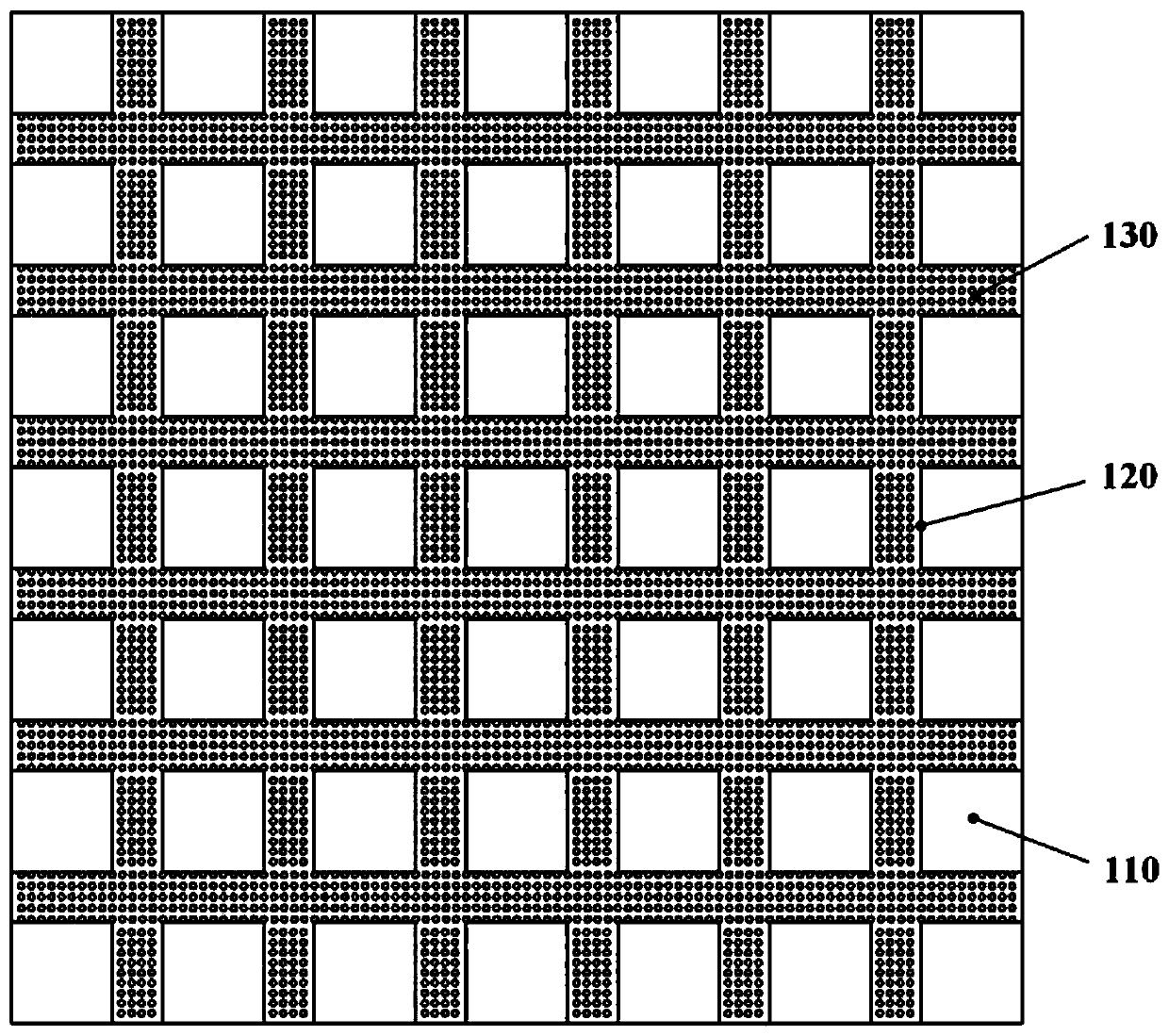

[0036] A self-cleaning flexible electrode with high light transmittance based on conducting polymers, as Figure 1~3 As shown, it consists of a flexible film substrate layer 110 , a conductive polymer microstructure layer 120 and a conductive polymer subwavelength structure layer 130 from bottom to top. The conductive polymer microstructure is in the shape of a rectangular groove, with a base width of 3 μm, a height of 5 μm, and a spacing of 20 μm, arranged in a rectangular array; the conductive polymer subwavelength structure is cylindrical, with a diameter of 100 nm and a height of 150 nm (that is, conductive polymer The thickness of the material subwavelength structure layer), with a spacing of 100nm, is arranged in a rectangular array on the top surface of the micron-scale grid structure.

[0037] Its preparation method, such as Figure 4 As shown, the steps are:

[0038] The conductive polymer (PEDOT:PSS) is uniformly coated on the flexible film substrate (PET) 110, and...

Embodiment 2

[0040] This embodiment is the same as Embodiment 1, except that the cylindrical shape of the conductive polymer subwavelength structure has a height of 120 nm.

[0041] The conductive polymer subwavelength structure is tuned by anodizing the mold.

Embodiment 3

[0043] This embodiment is the same as the embodiment 1, except that the height of the cylindrical shape of the conductive polymer subwavelength structure is 90 nm.

[0044] The conductive polymer subwavelength structure is tuned by anodizing the mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com