Heat-not-burning cigarette with hollow structure

A heat-not-burn and cigarette technology, which is applied to tobacco, smoke oil filter elements, and cigar manufacturing, etc., can solve the problems of high processing cost, increased suction resistance, and increased cost, and achieve large contact area, uniform mixing, and easy reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

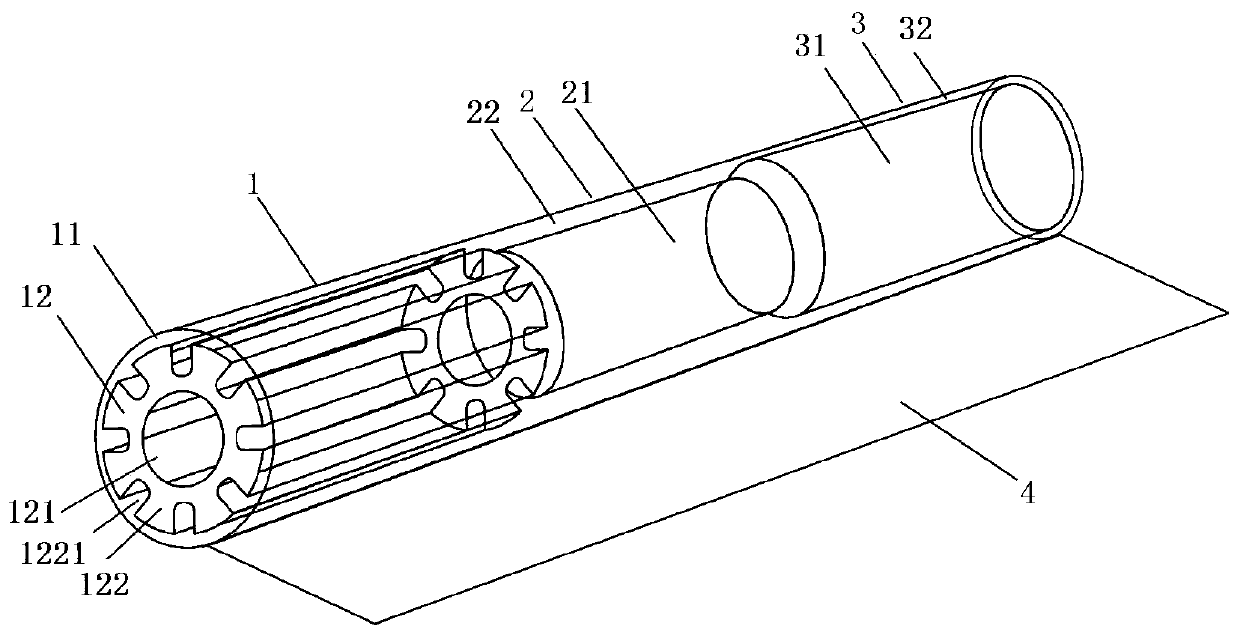

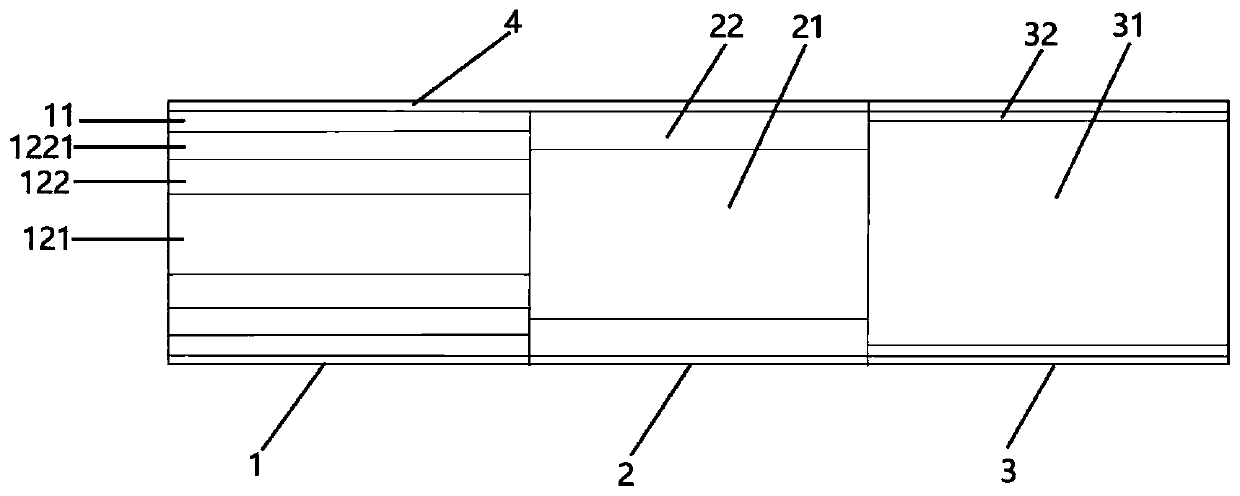

[0042] This embodiment is the preparation of a heat-not-burn cigarette with a hollow structure, which sequentially includes: a smoking core material section 1, a support section 2, and a filter section 3;

[0043] The smoking core material section 1 includes an outer wrapping tube 11 and a smoking core material rod 12. The smoking core material rod 12 is a hollow structure with a first lumen 121 and a first tube wall 122; the first There is an axially extending groove 1221 on the tube wall 122, and the opening of the groove 1221 faces away from the first lumen 121;

[0044] The support section 2 has a second lumen 21 and a second tube wall 22;

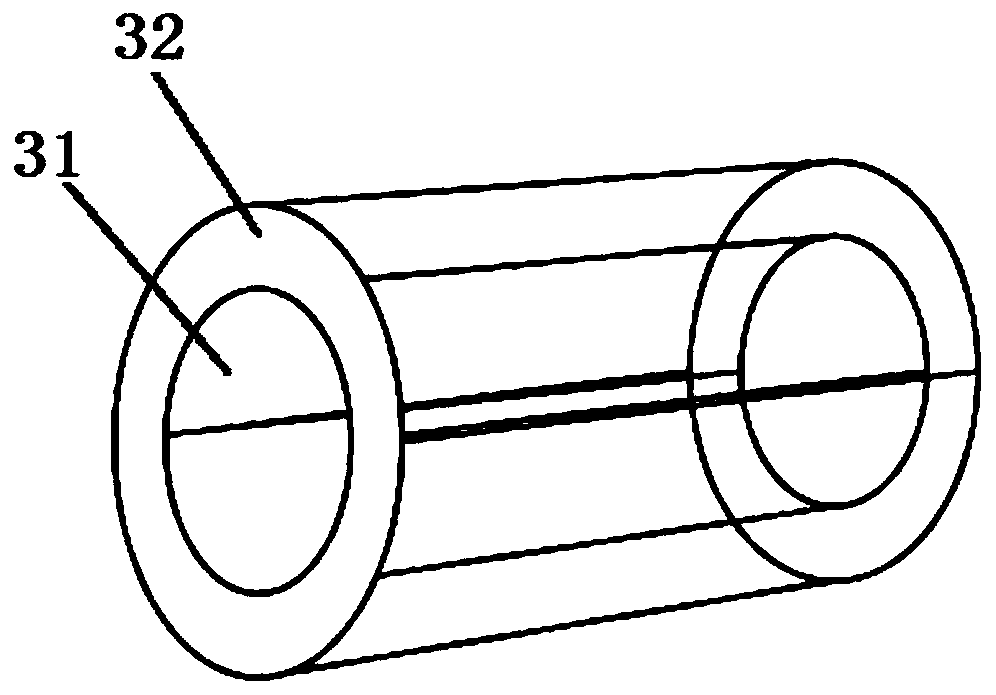

[0045] The filter segment 3 has a third lumen 31 and a third tube wall 32;

[0046] The smoking core section 1, the support section 2 and the filter section 3 are wrapped and formed by an outer cladding 4;

[0047] The groove 1221 axially extends the entire length of the first pipe wall 122; the number of the groove 1221 is 8; the cr...

Embodiment 2

[0062] This embodiment is the preparation of a heat-not-burn cigarette with a hollow structure, which sequentially includes: a smoking core material section 1, a support section 2, and a filter section 3;

[0063] The smoking core material section 1 includes an outer wrapping tube 11 and a smoking core material rod 12. The smoking core material rod 12 is a hollow structure with a first lumen 121 and a first tube wall 122; the first There is an axially extending groove 1221 on the tube wall 122, and the opening of the groove 1221 faces away from the first lumen 121;

[0064] The support section 2 has a second lumen 21 and a second tube wall 22;

[0065] The filter segment 3 has a third lumen 31 and a third tube wall 32;

[0066] The smoking core section 1, the support section 2 and the filter section 3 are wrapped and formed by an outer cladding 4;

[0067] The groove 1221 axially extends the entire length of the first pipe wall 122; the number of the groove 1221 is 8; the cr...

Embodiment 3

[0077] This embodiment is the preparation of a heat-not-burn cigarette with a hollow structure, which sequentially includes: a smoking core material section 1, a support section 2, and a filter section 3;

[0078] The smoking core material section 1 includes an outer wrapping tube 11 and a smoking core material rod 12. The smoking core material rod 12 is a hollow structure with a first lumen 121 and a first tube wall 122; the first There is an axially extending groove 1221 on the tube wall 122, and the opening of the groove 1221 faces away from the first lumen 121;

[0079] The support section 2 has a second lumen 21 and a second tube wall 22;

[0080] The filter segment 3 has a third lumen 31 and a third tube wall 32;

[0081] The smoking core section 1, the support section 2 and the filter section 3 are wrapped and formed by an outer cladding 4;

[0082] The groove 1221 axially extends the entire length of the first pipe wall 122; the number of the groove 1221 is 8; the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com