Local vacuum sealing tool for laser welding and laser welding device

A technology of laser welding and partial vacuum, which is applied in the direction of laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low welding efficiency and large size limitation of workpieces, and achieve high practicability, short vacuuming time, and large volume of vacuum chamber small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

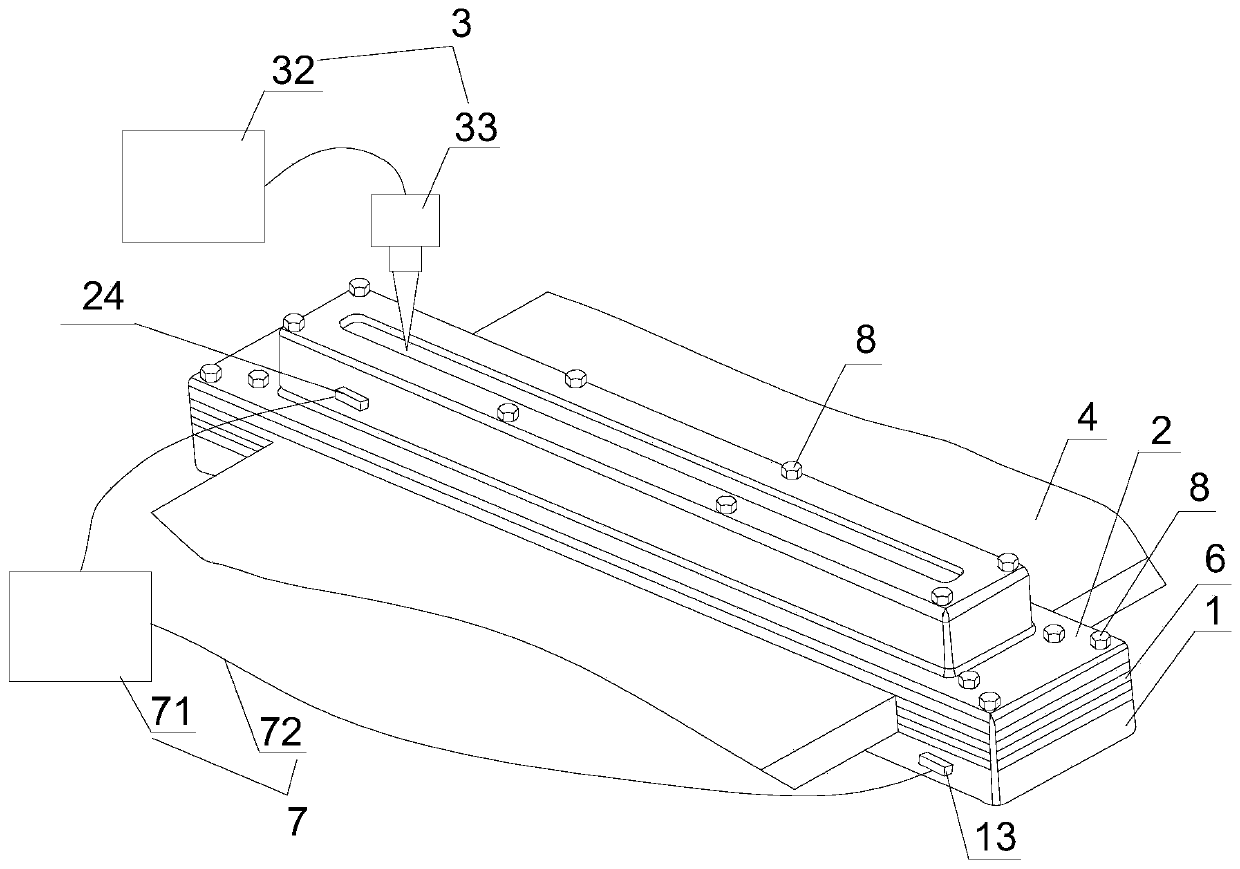

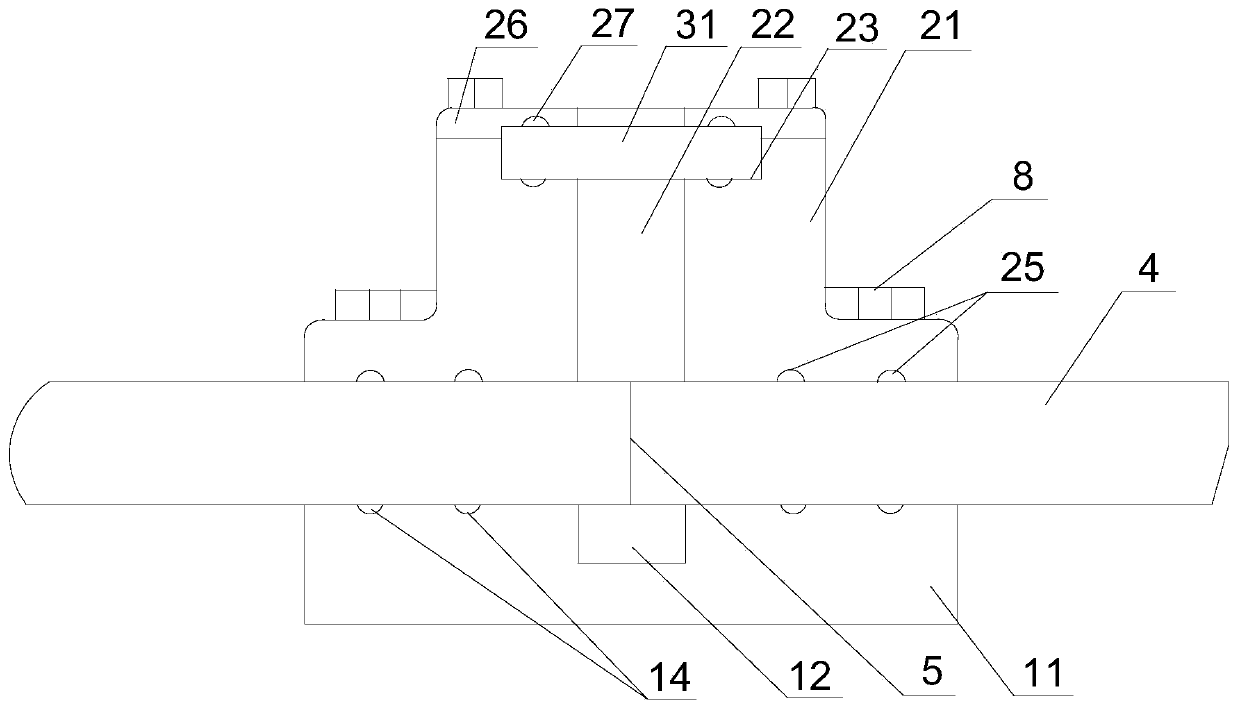

[0050] This embodiment provides a local vacuum sealing tool for laser welding, including a sealing cover I1 and a sealing cover II2. The sealing cover I1 includes a body I11, and a vacuum groove I12 is provided on one side of the body I11. The body I11 has a cuboid plate structure , the extension direction of the vacuum groove I12 is in the same direction as the axis direction of the body I11; the sealing cover II2 includes the body II21, the vacuum groove II22 is provided on one side of the body II21, and the other side of the body II21 is equipped with a mounting Groove 23, the extension direction of the installation groove 23 is in the same direction as the extension direction of the vacuum groove II 22, and the installation groove 23 communicates with the vacuum groove II 22 in the extension direction, and the installation groove 23 is used to seal and fix the laser protection lens 31; the body II 21 is similar to Cuboid structure, radial cross-section is "convex" shape str...

Embodiment 2

[0053] Further improvement on the basis of Example 1, the side plate of the body I11 is also provided with a sealing ring I14 distributed inside and outside, and the sealing ring I14 is distributed in a continuous closed loop along the circumference of the vacuum groove I12 notch, and is used for sealing pressure. Immediately between one side of the main body I11 and the plate surface of the plate 4 to be welded. There are also two sealing rings II25 distributed inside and outside on one side of the body II21. The sealing rings II25 are distributed in a continuous closed loop along the circumference of the notch of the vacuum groove II22, and are used for sealing and pressing on the side plate of the body II21 and Between the board faces of the flat plate 4 to be welded.

Embodiment 3

[0055] Further improvement on the basis of Embodiment 2, the sealing cover II2 also includes a hollowed-out lens pressing plate 26, the lens pressing plate 26 covers the mounting groove 23; Sealing gasket 27; when in vacuum use state, between the plate surface of lens pressing plate 26 and laser protection lens 31 one side plate surface is sealed and contacted by sealing gasket 27, between the bottom surface of mounting groove 23 and laser protection lens 31 other side plate surface The contact between them is sealed by the sealing gasket 27. The lens pressing plate 26 is fixed on the body II 21 by bolts 8. There are strip holes on the lens pressing plate 26. The strip holes are used for the laser to pass through and directly shine on the laser protection lens 31. The length of the strip holes extends in the same direction as the installation groove 23. The extension directions of are in the same direction, and the extension lengths of the two are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com