Method for detecting tiny faults of high-speed train air braking system

A technology for fault detection and high-speed trains, applied in brake safety systems, brakes, brake components, etc., can solve problems such as poor fault detection results of multiple sensors, and achieve easy computer implementation, timely and accurate fault detection, and a small amount of calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

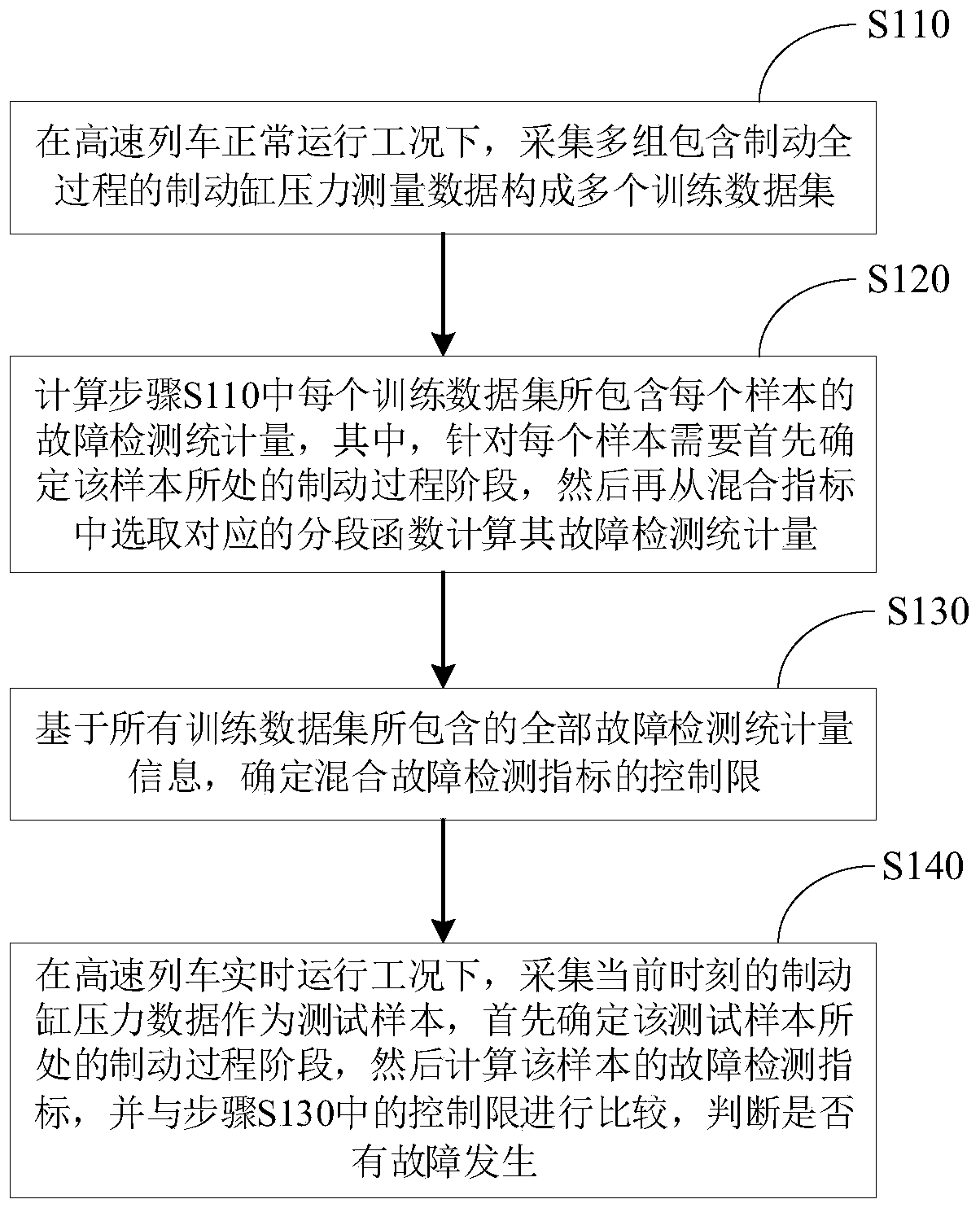

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

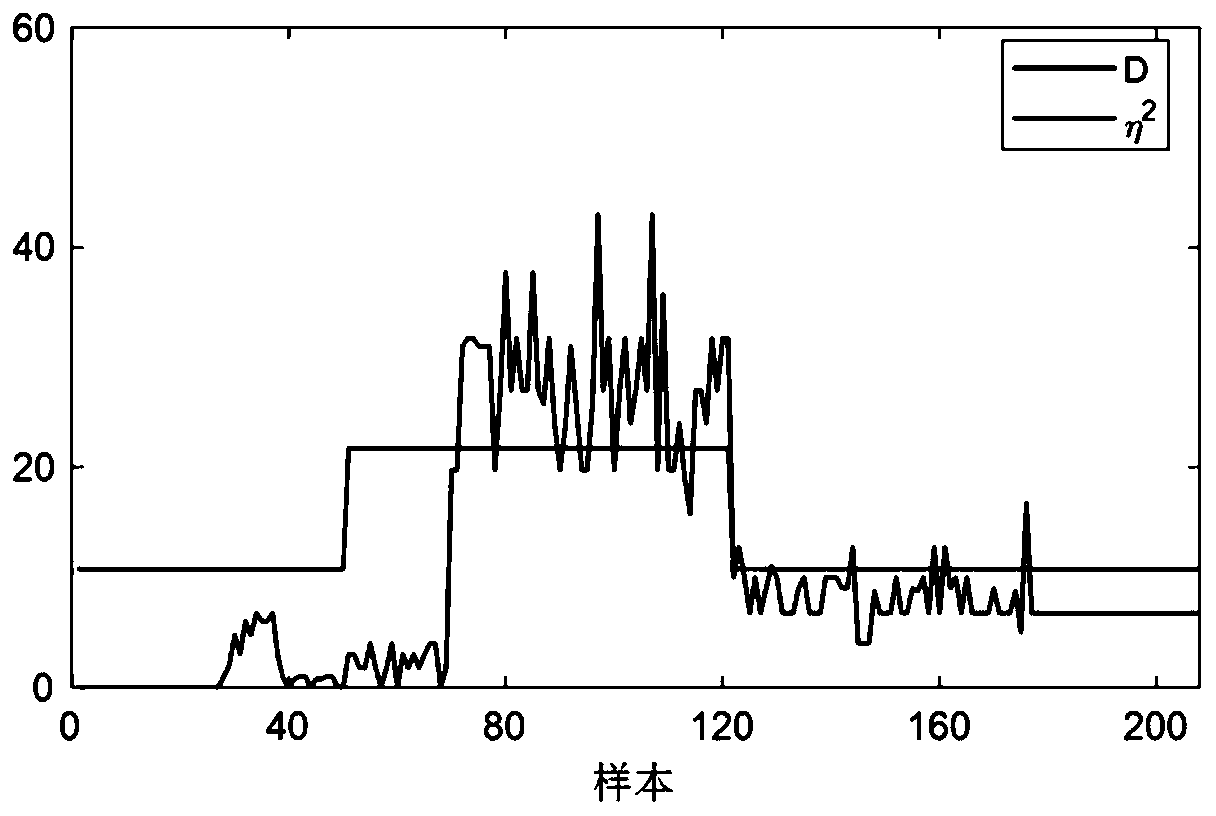

[0042]The purpose of the present invention is to implement on-line monitoring of the high-speed train air brake system, and timely detect possible abnormalities in the valve parts or control loops, brake cylinder parts and gas transmission pipelines in the brake control unit. Considering that the braking action intends to evenly distribute the braking force to multiple brake cylinders installed on each train of a high-speed train, under normal circumstances, the pressure of multiple brake cylinders in each train should tend to be consistent. Based on such a consideration, the present invention adopts the measure of variance to measure the degree of dispersion among multiple brake cylinder pressure measurement values in the application, release and traction phases of the braking process, so as to detect abnormal conditions in time. In addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com