Large-span stadium building cable membrane structure

A large-span, venue technology, applied in the direction of building components, special structures, building structures, etc., can solve the problems of high cost, poor economy of stadium roofs, large steel consumption, etc., to achieve reduced steel consumption, reasonable force, large span effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

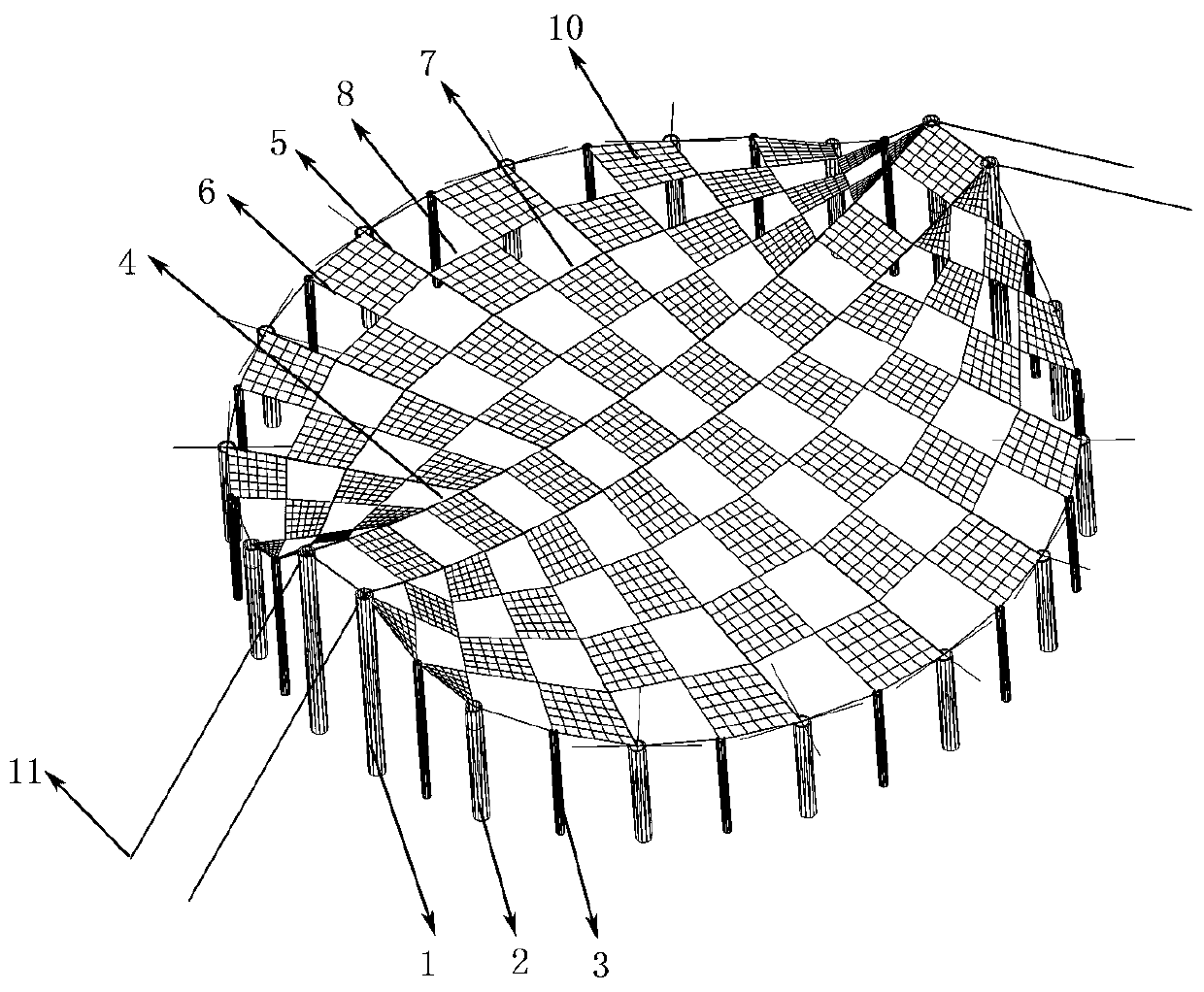

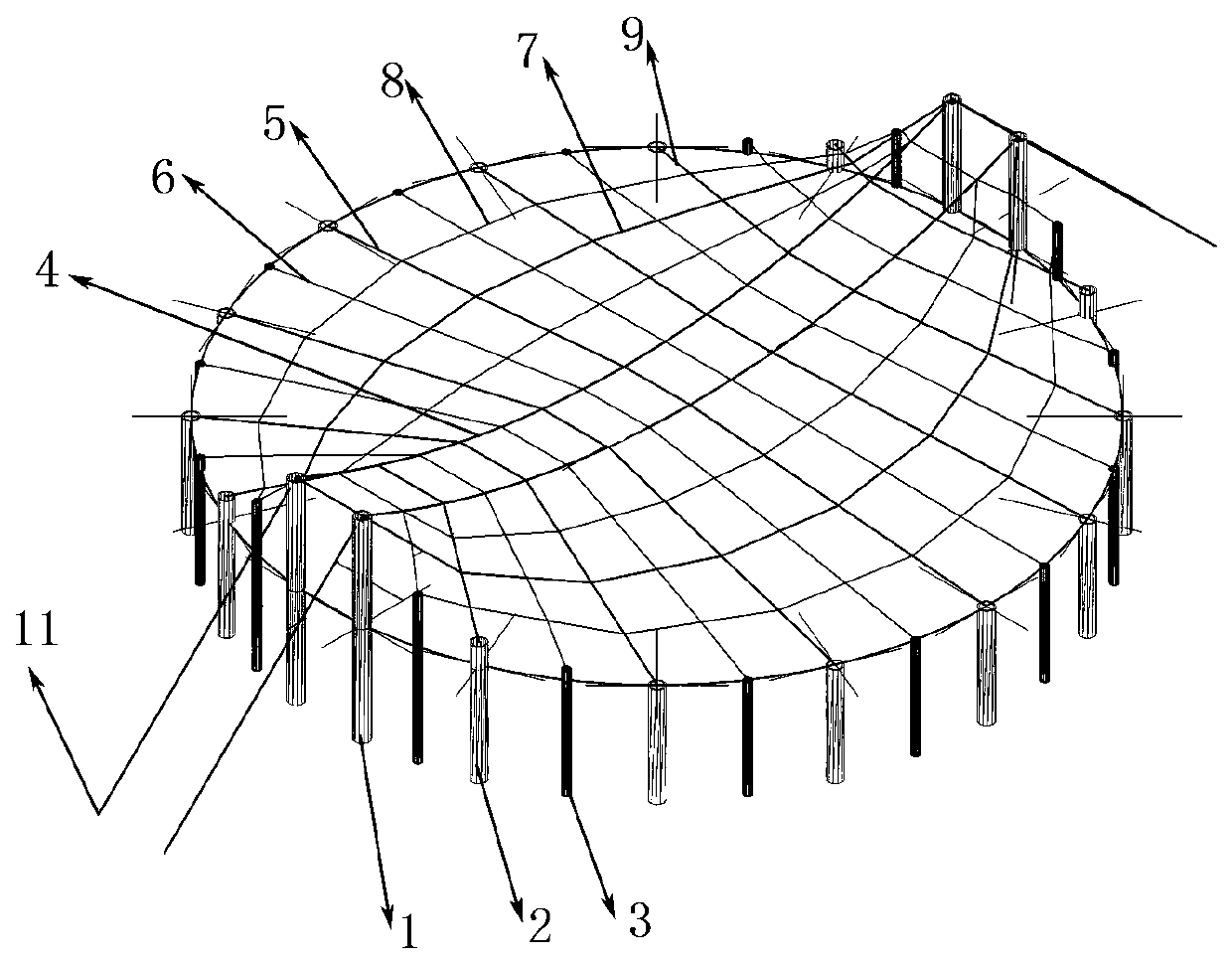

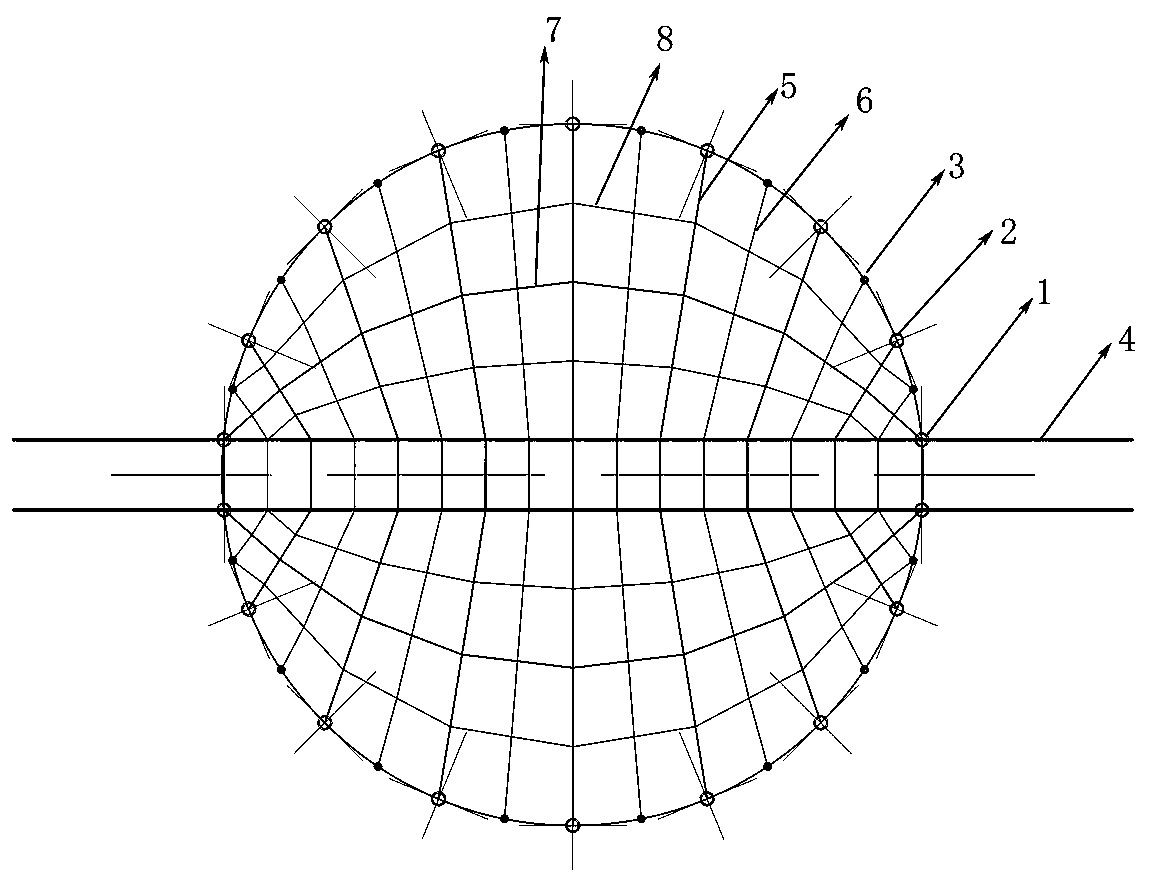

[0019] Embodiment 1: A kind of cable-membrane structure of long-span venue building, such as Figure 1-4 As shown, it includes multiple pairs of uprights arranged vertically, and radial steel cables and / or latitudinal steel cables are drawn between each upright and other uprights, and multiple radial steel cables and latitudinal steel cables are interwoven to form The support net is covered with a roof membrane 10 on the support net. In the present invention, the columns include a main tower column 1, a stabilizing column 2 and a distribution column 3, and the main tower column 1, the stabilizing column 2 and the distribution column 3 are arranged in pairs respectively, wherein the diameter of the main tower column 1 is greater than the diameter of the stabilizing column 2 greater than the diameter of the distribution column 3, the main load-bearing cable 4 is drawn between each pair of main tower columns 1, the latitudinal stability cable 5 is drawn between each pair of stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com