Building outer facade hollow brick installing structure and process

A technology for installing structures and facades, applied in building components, building structures, buildings, etc., can solve problems such as inability to decorate building facades, limited scope of application, etc., and achieve strong application value, strong integrity, and overall antique appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further described below, but protection scope of the present invention is not limited thereto:

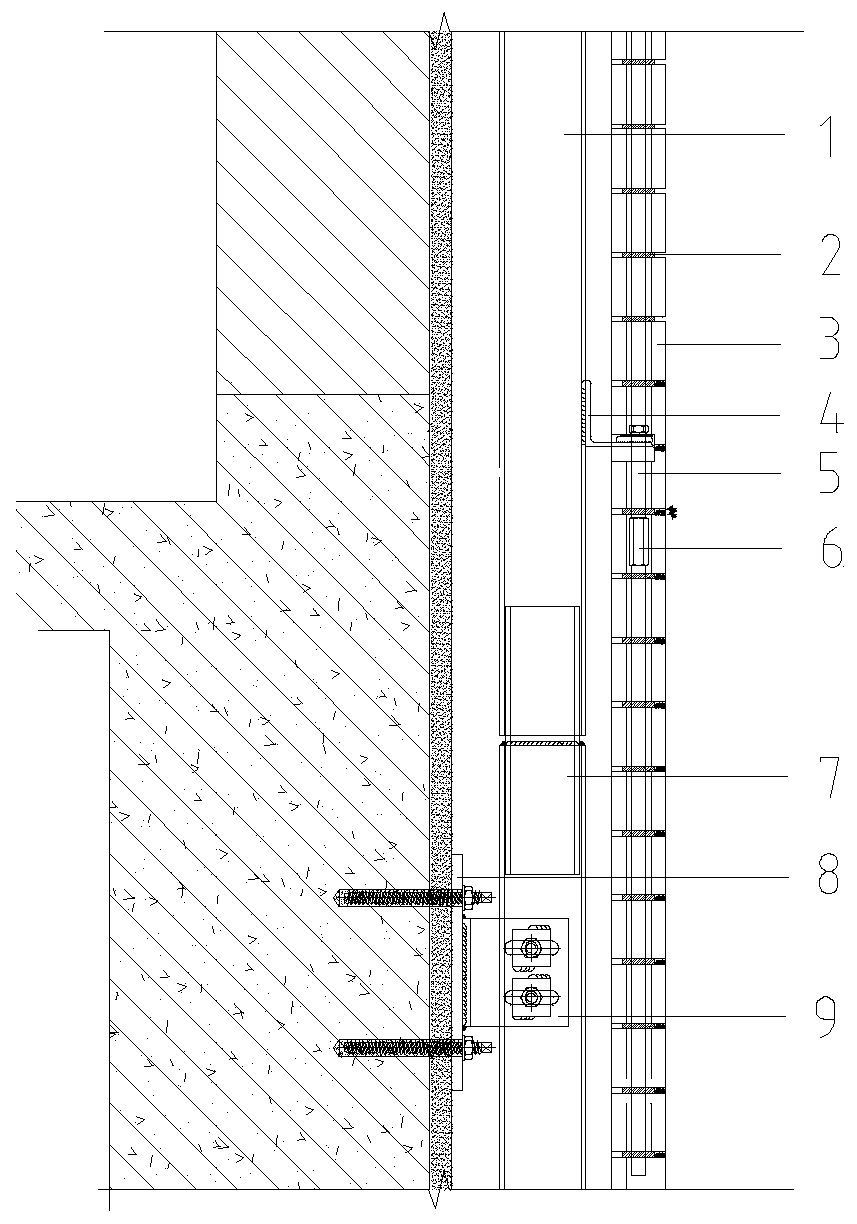

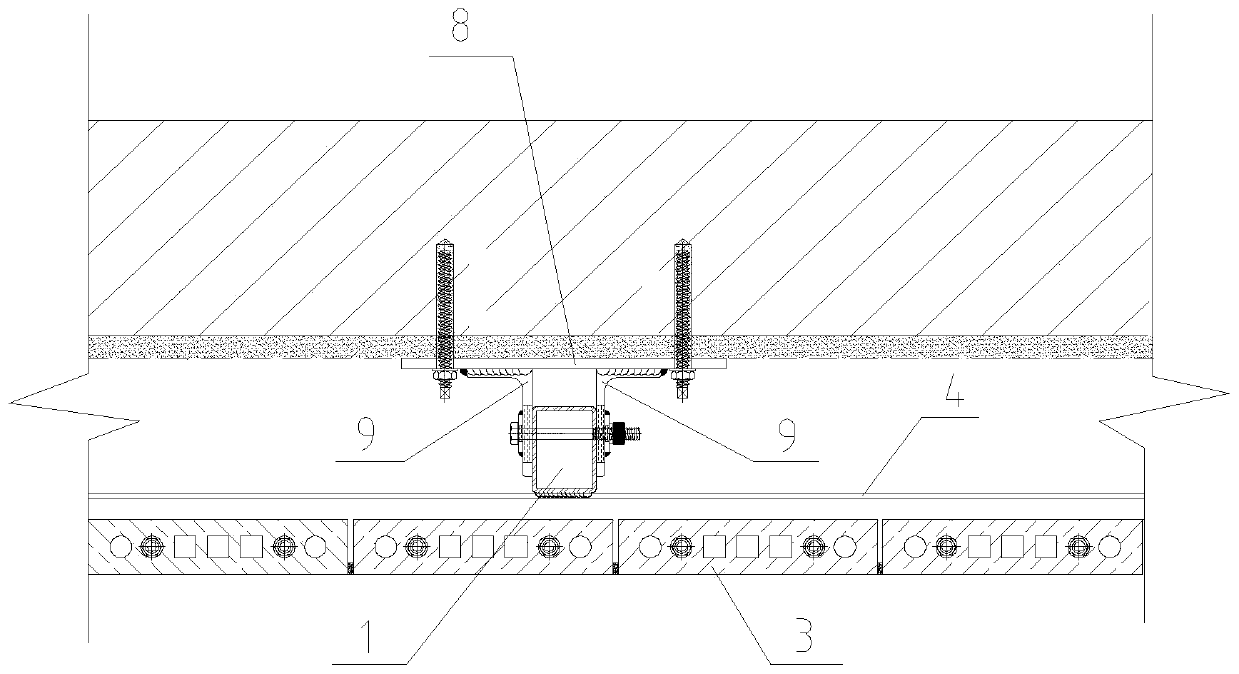

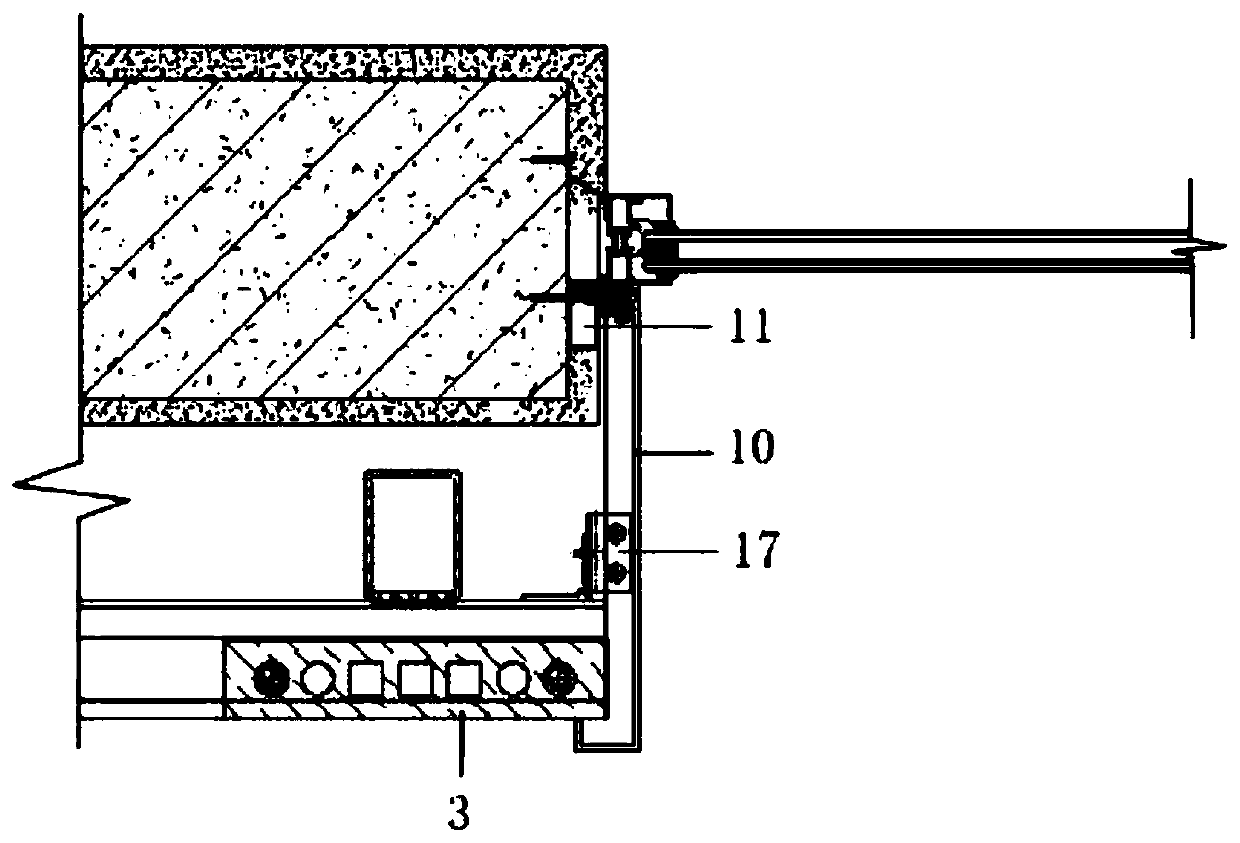

[0040] The installation structure of hollow bricks on the facade of the building includes a wall structure arranged on the surface of the wall and a hollow brick keel structure installed on the wall and arranged close to the wall structure. The wall structure includes the base shotcrete layer 12, Steel wire mesh 13, cement mortar layer 14, polyurethane waterproof coating layer 15 and elastic coating layer 16, hollow brick keel structure includes main keel 1, secondary keel 4, corner code 9 and embedded parts 8, secondary keel 4 is welded to main keel 1 On the top, the main keel 1 is fixed on the corner bracket 9, and the corner bracket 9 is welded and fixed with the embedded part 8. The secondary keel 4 is threaded with a screw 5, and the screw 5 is pierced with a hollow brick 3, so that the hollow brick 3 is full Paved on the facade of the building....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com