Test system and method for seepage situation of fused salt leaked from photo-thermal power generation and heat storage system in foundation

A heat storage system and photothermal power generation technology, applied in the direction of solar thermal power generation, solar heating system, solar heat storage, etc., can solve the problems of tank rupture, different thermal expansion, tank deformation, etc., to achieve the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

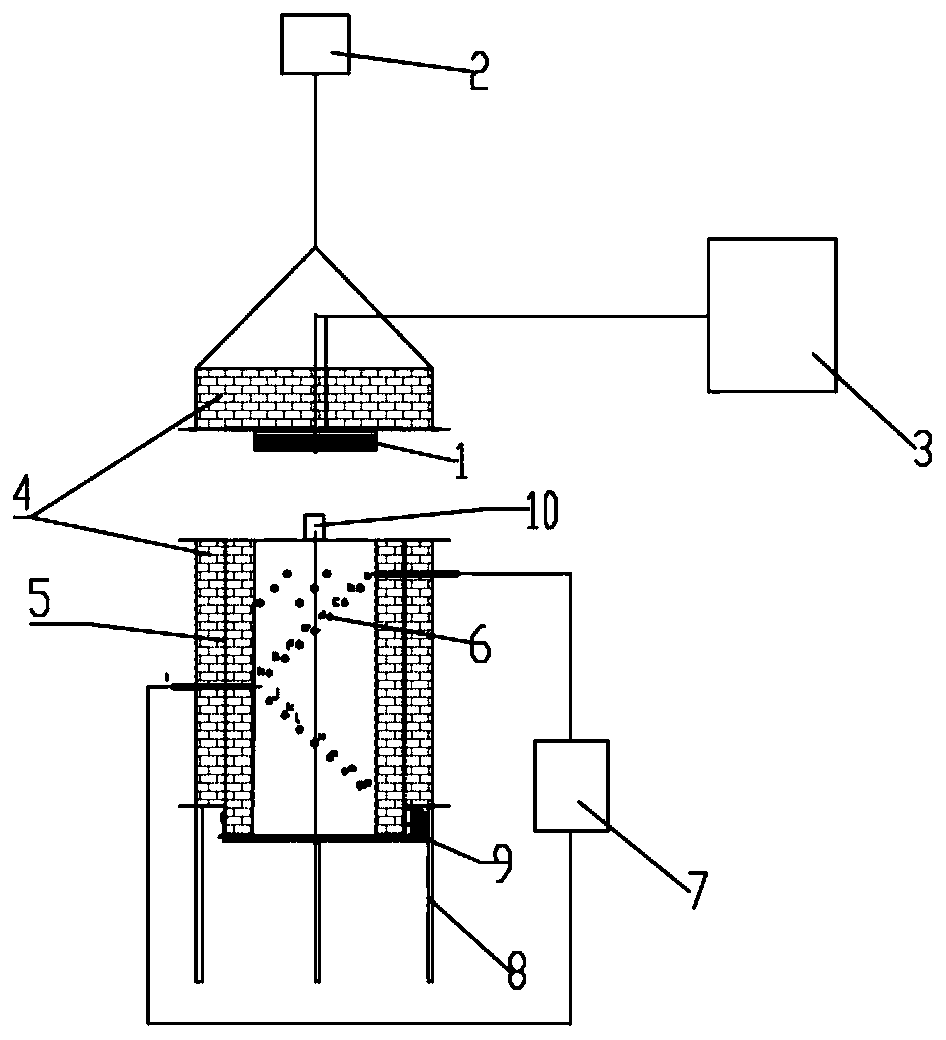

[0033] Such as figure 1 As shown, a test system for seepage of leaking molten salt in the foundation is suitable for thermal power generation molten salt heat storage system, which specifically includes a heating plate 1 with a lifting device 2, a tank body 5 stacked on the foundation and its insulation material 4 And support 8, temperature sensor 6, temperature control device 3 and temperature recording device 7, crucible 10.

[0034] The heating plate 1 can effectively and concisely simulate the heating of the foundation by the molten salt storage tank. The heating plate is installed with a temperature sensor and an electric heating wire, and is connected to the temperature control device 3. The heating temperature is regulated by controlling the electric heating power; The particle size, proportion and compaction are filled in the tank body 5, and the wall surface of the foundation accumulation tank body and the top of the heating plate are equipped with insulation material...

Embodiment 2

[0037] According to the test system in Example 1, the test method for the seepage of molten salt leakage in the foundation of the solar-thermal power generation heat storage system includes the following steps:

[0038] S1, the heating plate 1 is raised, the foundation material is filled in the tank body 5 according to the particle size and thickness requirements, and the foundation material is compacted according to the compaction requirements;

[0039] S2, lower the top heating plate 1, tightly combined with the upper part of the tank body 5, turn on the heating device 3, the temperature of the heating plate rises to the actual operating temperature of the molten salt tank, turn on the temperature test 6 and the recording device 7, and maintain the heating state to the foundation in the tank The temperature distribution of the material reaches an equilibrium state;

[0040] S3, raising the heating plate 1, placing a crucible 10 with a leakage hole in the center of the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com