Multi-angle rotary fixing frame for assembling lithium battery

A multi-angle, lithium battery technology, applied in primary batteries, equipment for manufacturing primary batteries, battery assembly machines, etc., can solve problems such as inconvenient operation, and achieve the effect of good adaptability and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

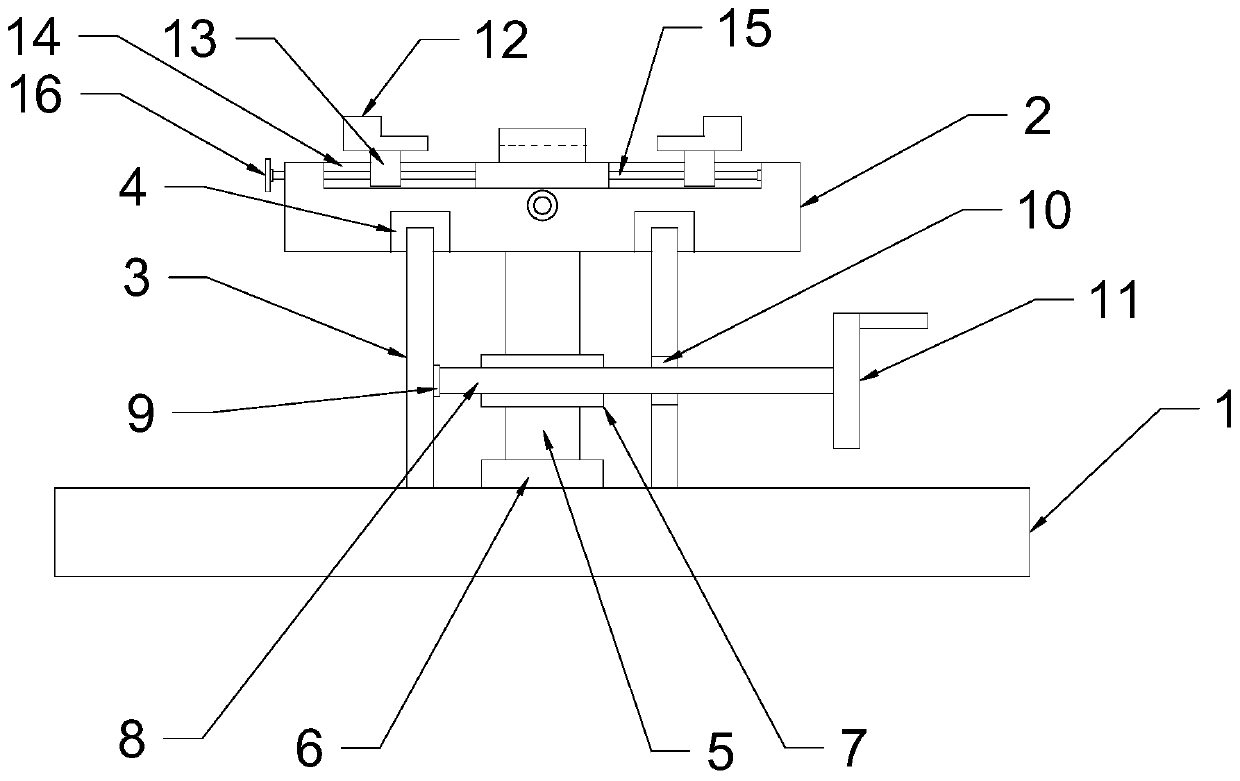

[0020] see Figure 1-3 , in an embodiment of the present invention, a multi-angle rotating fixed frame for lithium battery assembly, including a base 1 and a bearing plate 2; a bearing plate 2 is provided above the base 1, and a support cylinder 3 is fixedly connected to the upper end of the base 1 , the upper end of the support cylinder 3 is nested in the bearing plate 2, the lower end surface of the bearing plate 2 is provided with an annular groove 4, the upper part of the support cylinder 3 is nested in the annular groove 4 and is slidably connected with the annular groove 4, the support cylinder 3 is on the bearing plate 2 Support is provided to increase the load capacity of the carrying tray 2 .

[0021] The central position of the lower end surface of the bearing plate 2 is fixedly connected with a central shaft 5, and the lower end of the central shaft 5 is rotationally connected with the base 1 through the first bearing seat 6; the central shaft 5 is sleeved and fixed...

Embodiment 2

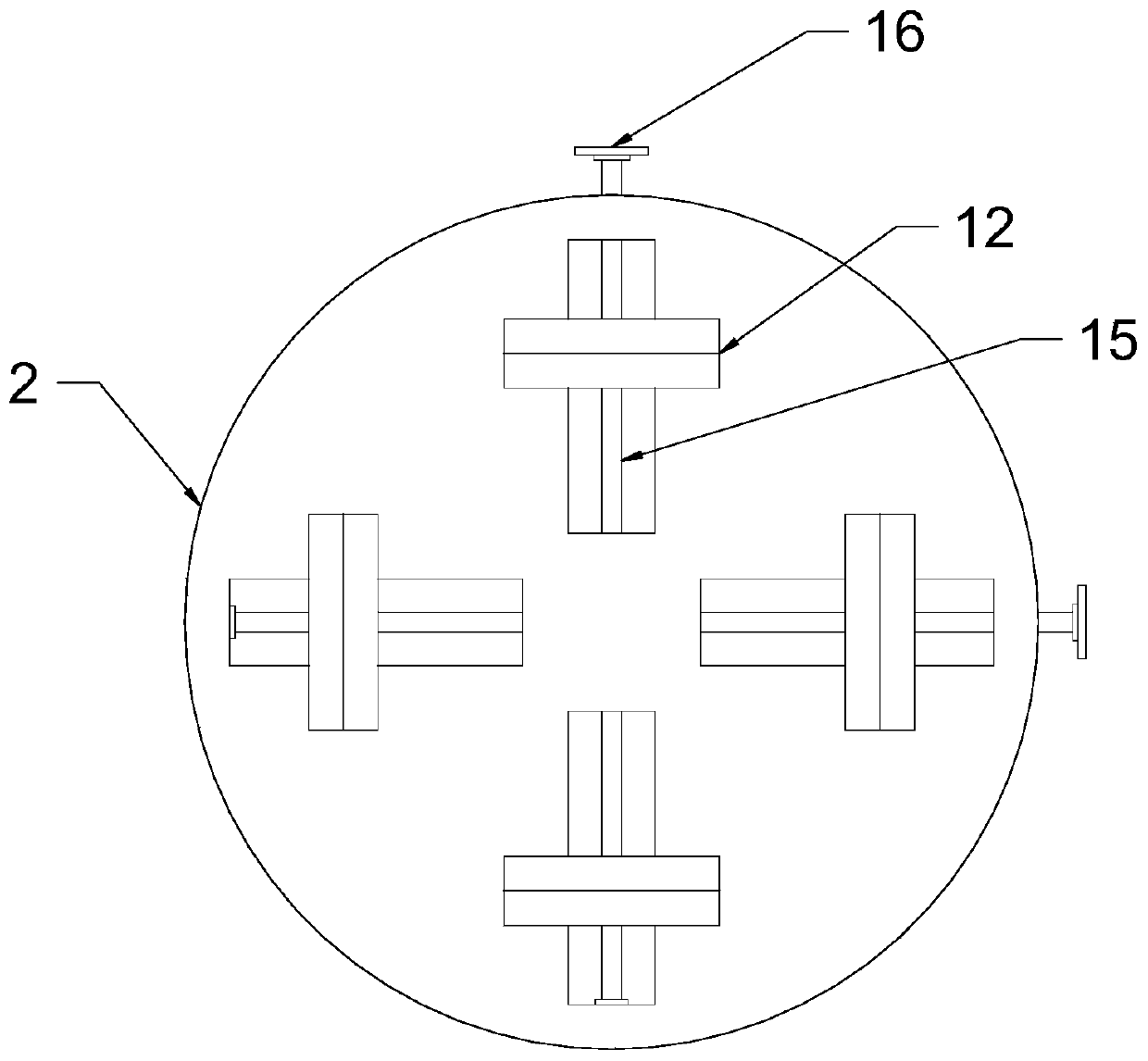

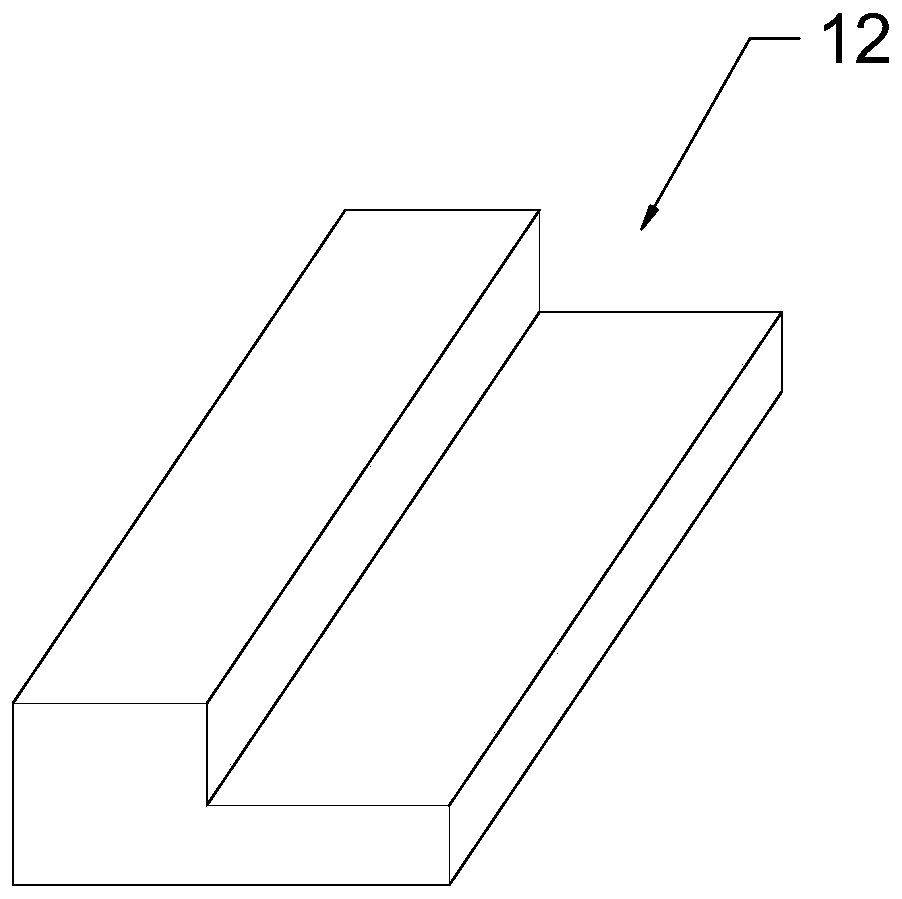

[0023] The difference between this embodiment and Embodiment 1 is that two sets of clamping blocks 12 are arranged opposite to each other above the carrier plate 2, and the clamping blocks 12 are stepped, which is convenient for clamping and fixing the edge of the lithium battery insulation board to be installed. , and then the lithium battery insulation board to be installed is fixed to facilitate the plug-in installation of the battery cell and when the insulation tape is packaged, the first adjustment wheel 11 is rotated to carry out the winding package of the insulation tape, which is easy to operate and labor-saving.

[0024] A moving block 13 is fixedly connected below the clamping block 12, and a chute 14 cooperating with the moving block 13 is provided on the carrier plate 2, and the moving block 13 is nested in the chute 14 and is slidably connected with the chute 14; The chute 14 is nested with a two-way screw rod 15, the two-way screw rod 15 runs through the moving b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com