Cleaning equipment for food production

A technology for cleaning equipment and food, applied in the cleaning method using tools, the cleaning method using liquid, the cleaning method using gas flow, etc. and other problems, to achieve the effect of facilitating continuous cleaning, thorough cleaning, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

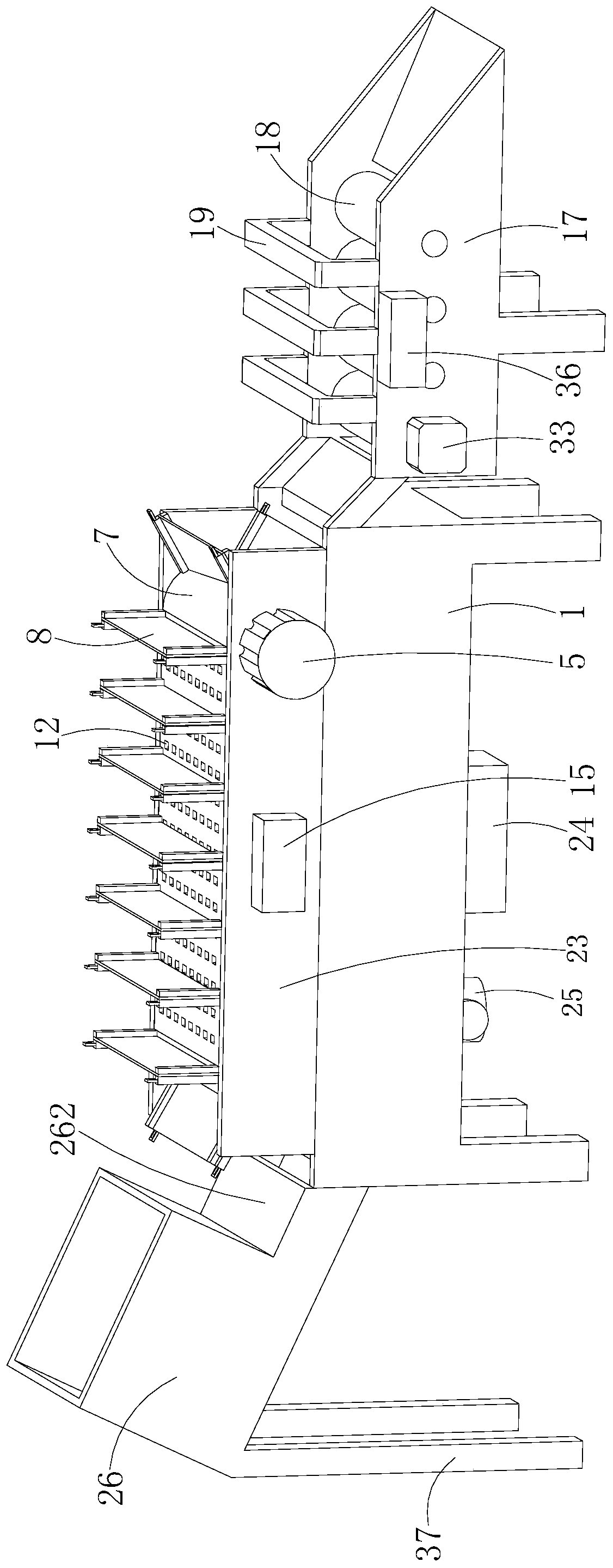

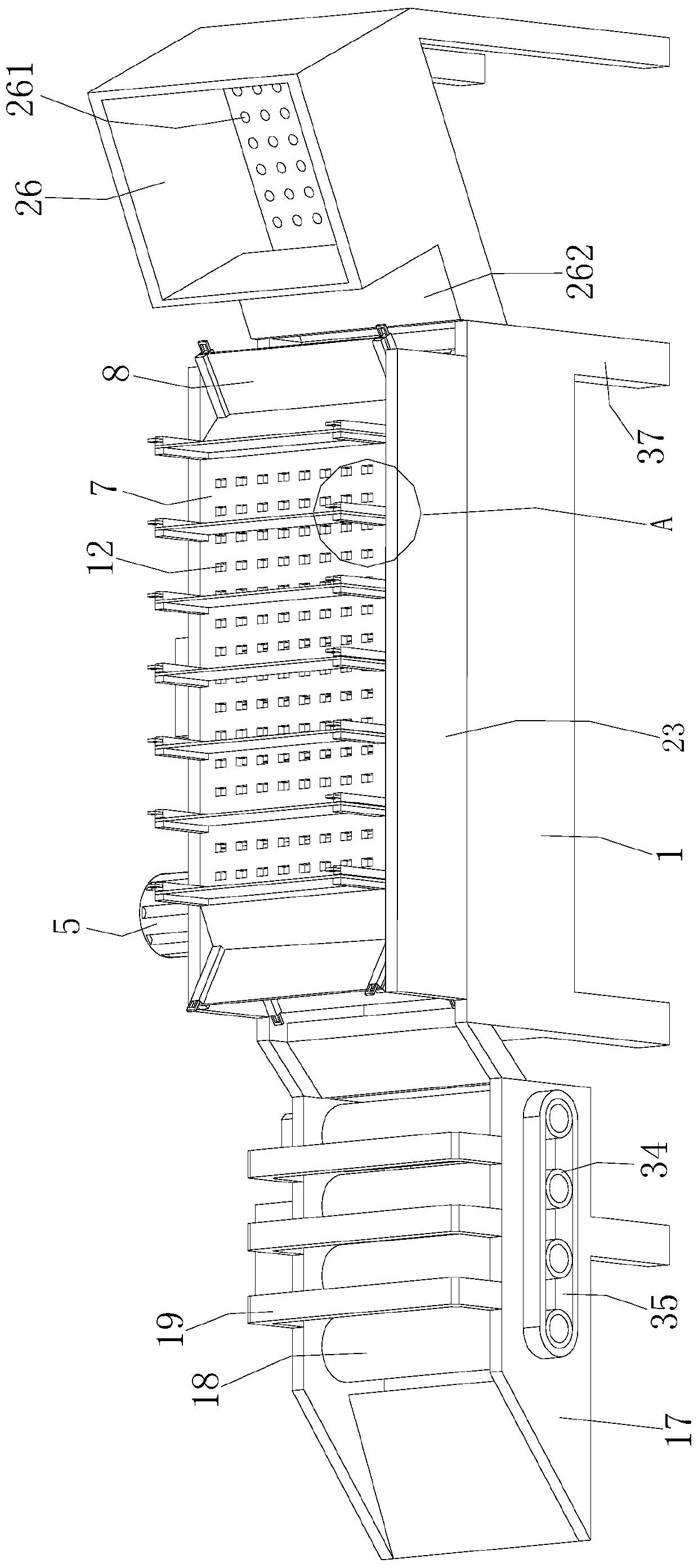

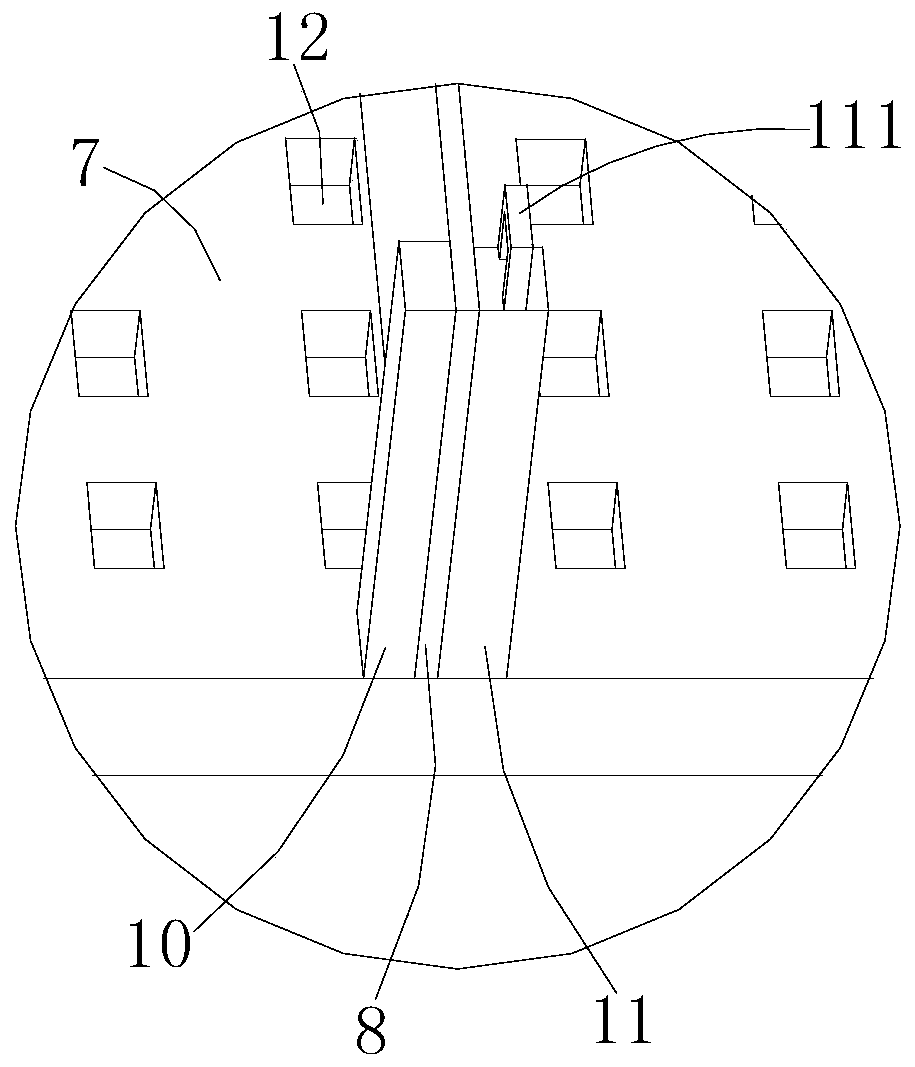

[0026] Such as Figure 1-5 As shown, a cleaning device for food production includes a cleaning platform 1 and a cleaning device arranged above the cleaning platform 1. The upper end of the cleaning platform 1 is concaved inward to form a cleaning tank 2, and the inner bottom of the cleaning tank 2 is evenly provided with a plurality of Air jet pipe 3, air pump 24 is installed at the bottom of cleaning platform 1, and air pump 24 is the common air pump that can be purchased directly on the market, and air jet pipe 3 is connected with air pump 24 through air pipe, and air jet pipe 3 is arranged obliquely, and its air jet direction is toward wiping Part 8, so that when the air jet pipe 3 sprays air, it promotes the mutual con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com