Self-excitation washing wet dust collector

A technology for wet dust collectors and dust removal chambers, which is applied in the field of dust collectors and self-excited cleaning wet dust collectors. Dust diffusion rate and effect of improving dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

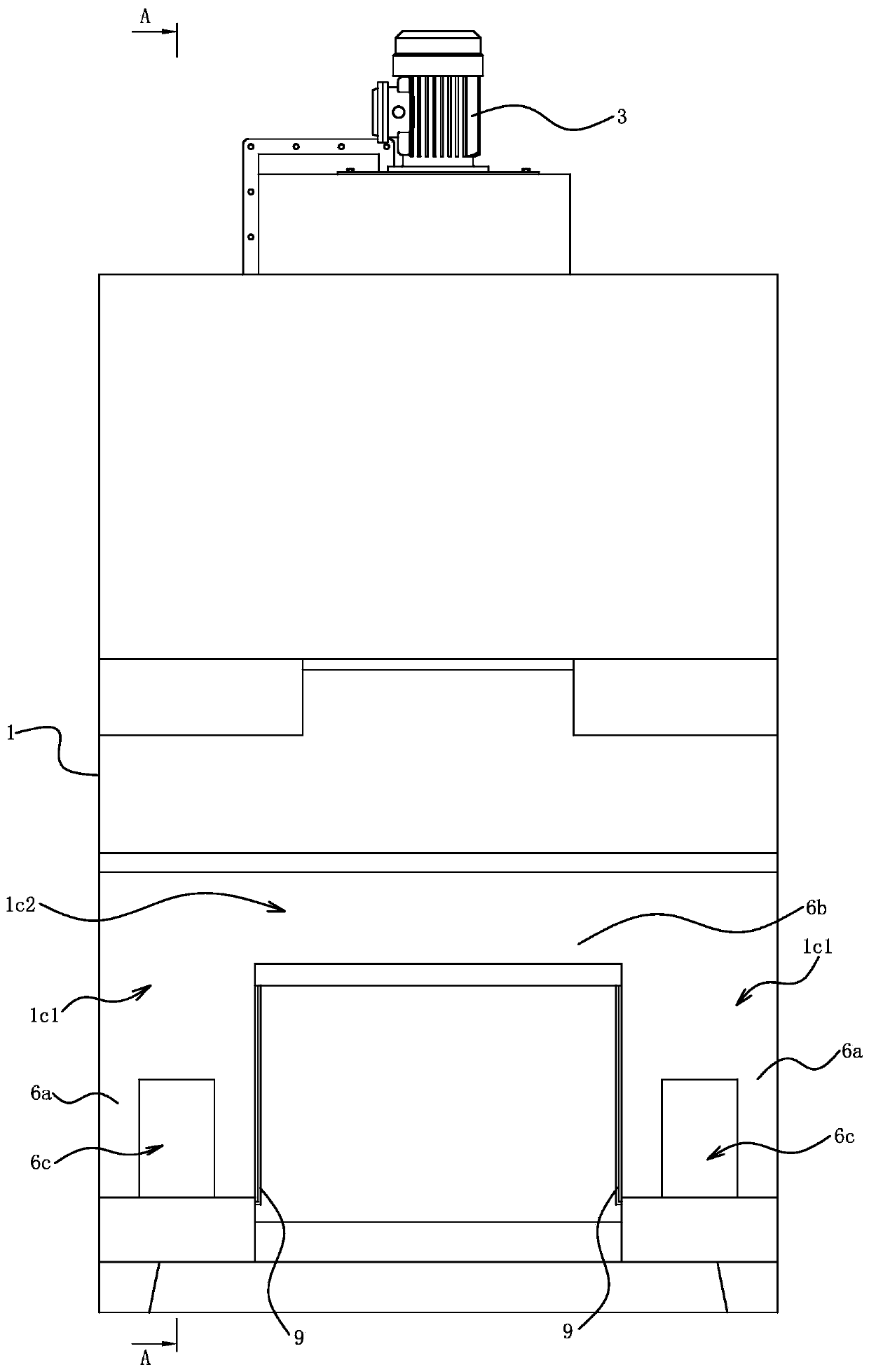

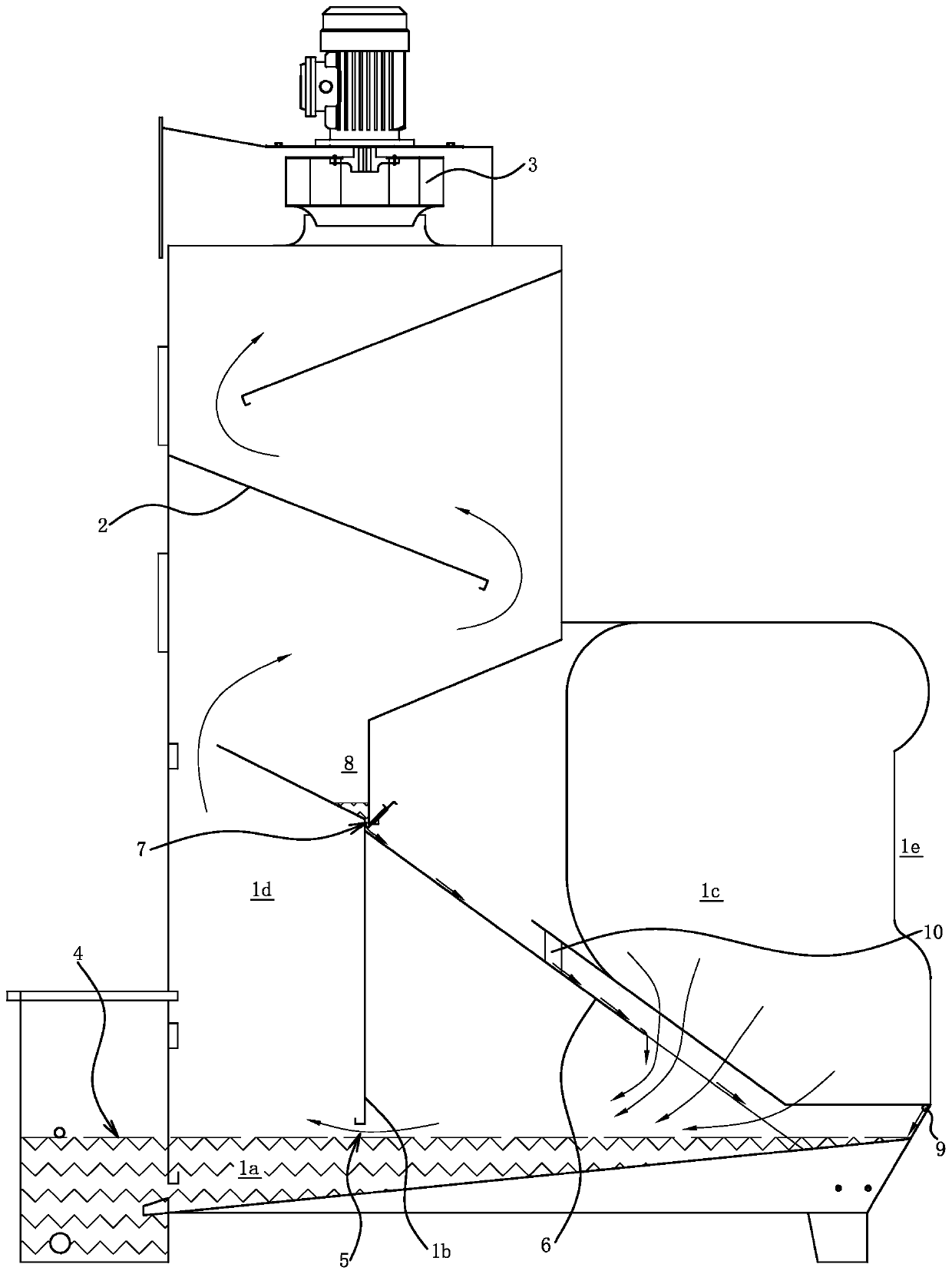

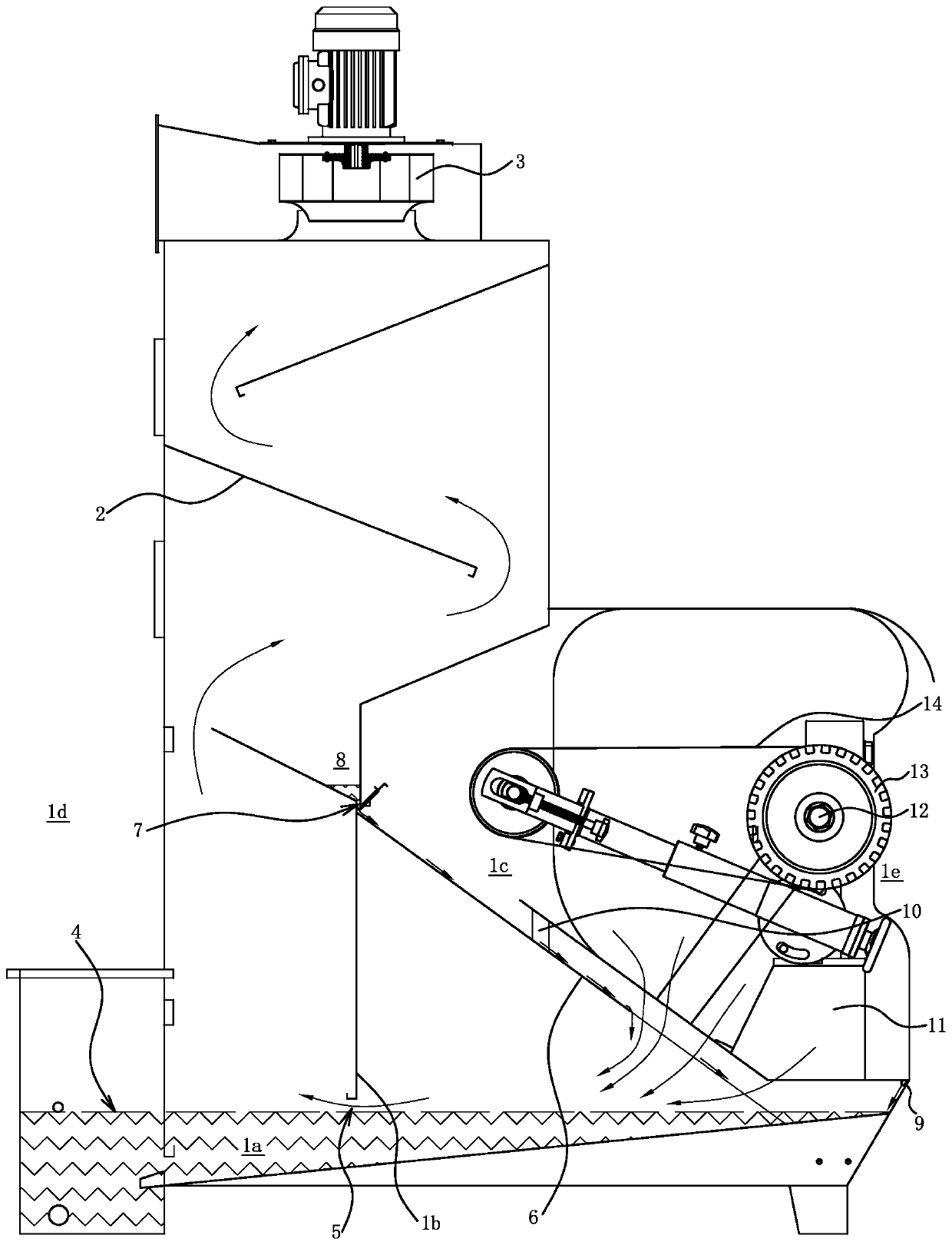

[0015] Embodiment one: if figure 1 with figure 2 As shown, a self-excited scrubbing wet dust collector includes a box body 1, a separation mechanism 2, a fan 3 and a water outlet structure.

[0016] The bottom of the inner cavity of the box body 1 is the water storage chamber 1a, and there is a partition 1b inside the box body 1. The side area is the dust removal chamber 1d; when the water storage chamber 1a holds water, a wind passage gap 5 is formed between the liquid surface 4 and the partition 1b, so that the dust collection chamber 1c and the dust removal chamber 1d are connected through the wind passage gap 5. There is a grinding control port 1e on the front side wall of the dust collection chamber 1c; the separation mechanism 2 is installed in the dust removal chamber 1d; an air outlet is opened on the top wall of the dust removal chamber 1d, and a fan is installed on the top wall of the dust removal chamber 1d 3. The vortex chamber of fan 3 communicates with the air...

Embodiment 2

[0028] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly. Only the differences will be described. The difference is that there is no water receiving tank 8 in the dust removal chamber 1d, The water outlet structure is a water outlet pipe, the side wall of the water outlet pipe has a drain hole, and the water outlet pipe is connected with the running water pipe, or a water pump is installed in the water storage chamber 1a, and the water outlet pipe communicates with the water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com