Sintering forming type 3D printer

A 3D printer and molding technology, which is applied in the direction of processing and manufacturing, solid material additive processing, processing accessories of main materials, etc., can solve the problem of large occupied space, and achieve the effect of reducing occupied space and occupying small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

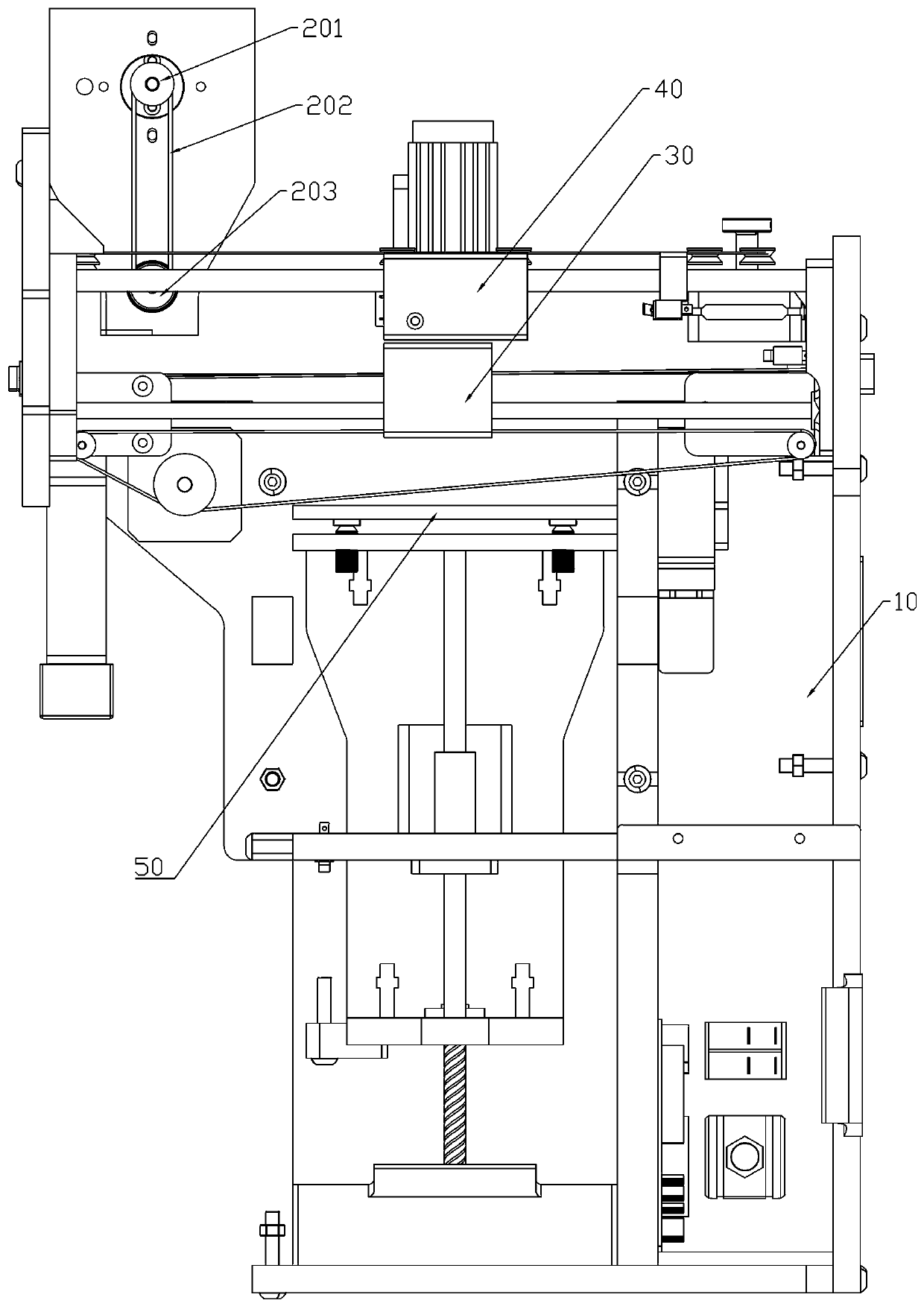

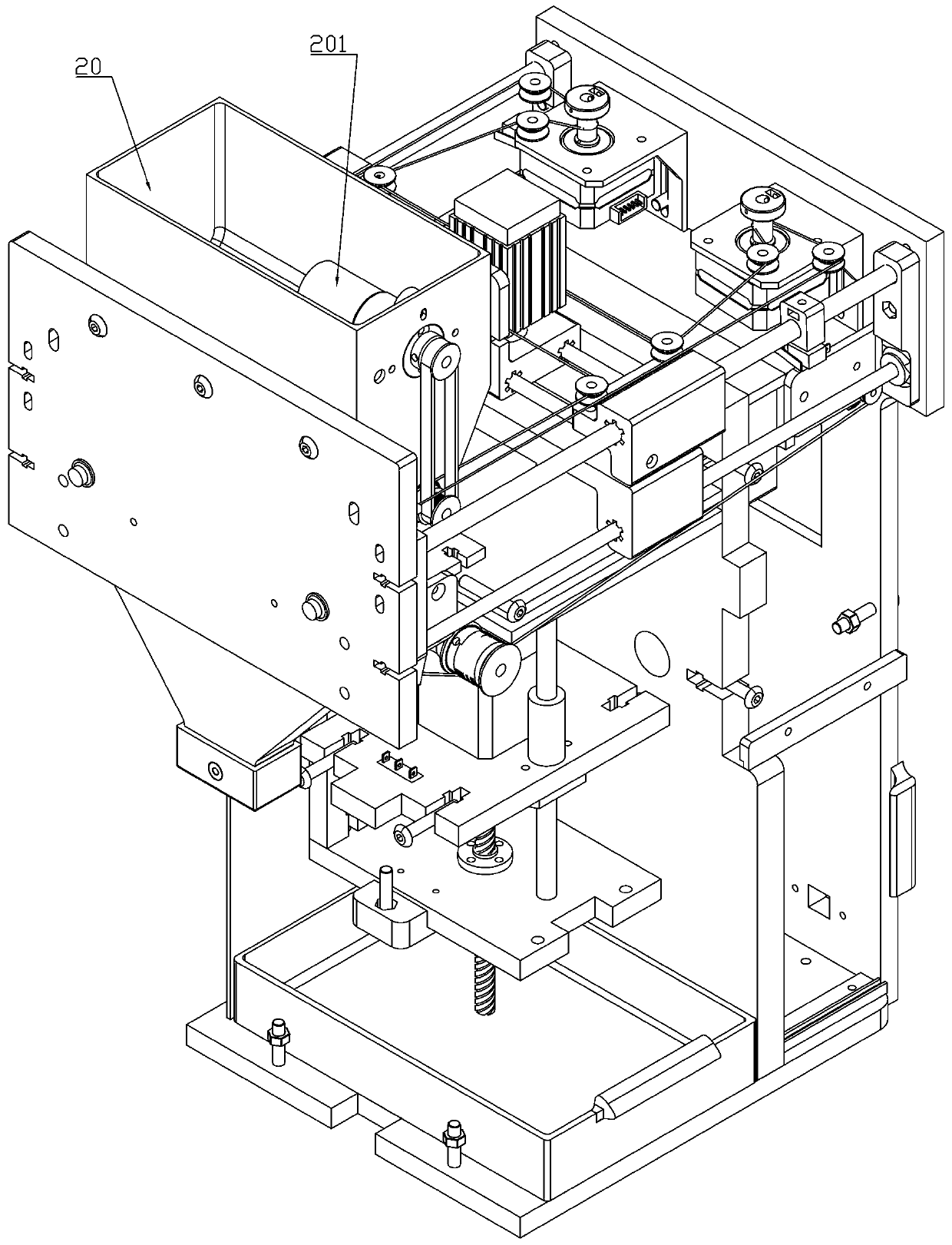

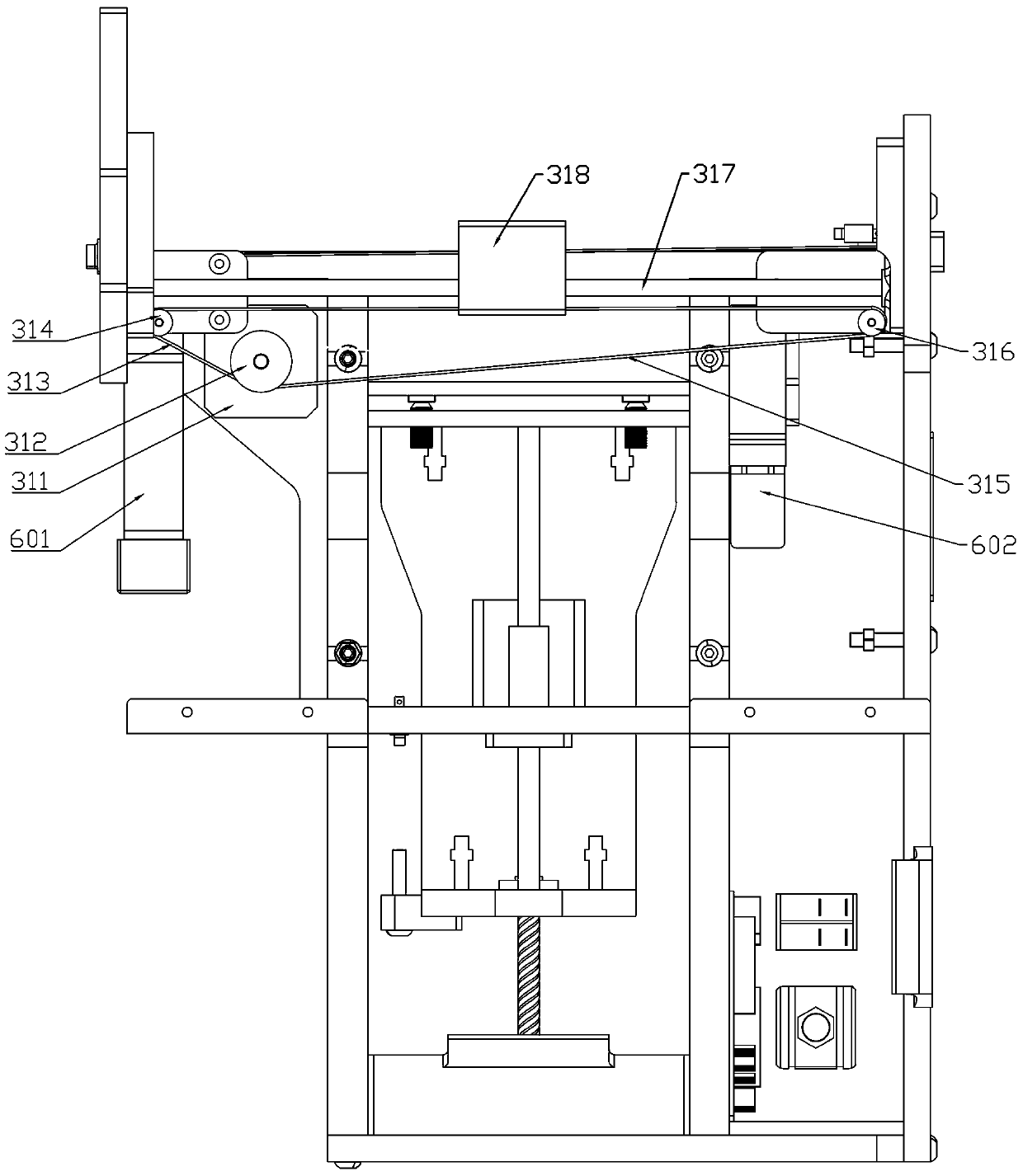

[0036] Embodiment 1: a kind of sintering molding type 3D printer, see Figure 1-6 , including a frame 10, a sintering material storage module 20, a Z-axis lifting sintering platform module 50, a sintering material layer laying module 30, a sintering head XY-axis plane moving module 40, and a sintering head 436. The sintering head 436 is installed on the movable block of the XY-axis plane moving module of the sintering head, and the sintering head 436 may be a laser sintering head. The frame 10 has a material spreading platform, on which a sintering platform material cylinder is arranged, and the sintering platform material cylinder is composed of a tubular cylinder body and a sintering platform 501 arranged in the tubular cylinder body, and the sintering platform 501 and the tubular cylinder body The sintering platform material cylinder is formed by sliding fit, and the sintering platform 501 is installed on the movable block of the Z-axis lifting module. Figure 5 Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com