Printing and dyeing industrial wastewater treatment apparatus

A technology for treating device and industrial wastewater, which is applied in multi-stage water treatment, water/sewage treatment, neutralized water/sewage treatment, etc., which can solve the problem of unsatisfactory wastewater treatment and purification effect, the inability of additives to achieve the treatment effect, and the reduction of pipeline flow. and other problems, to achieve the effect of high safety discharge passing efficiency, good automatic effect and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

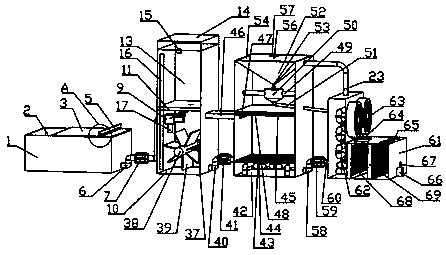

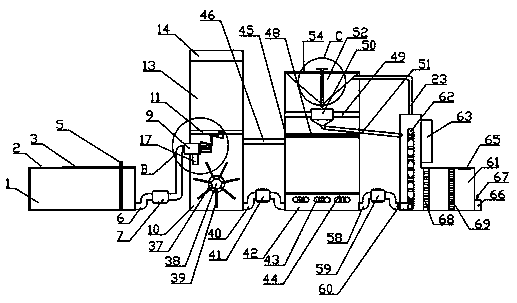

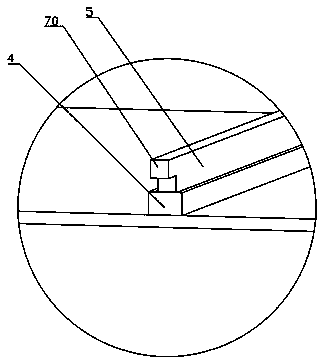

[0029] 2. If figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a printing and dyeing industrial wastewater treatment device of the present invention includes a wastewater tank 1, and is characterized in that: the wastewater tank 1 includes a water inlet 2 and a wastewater tank cover 3, and the wastewater tank cover 3 is connected with an outer convex groove 4, and the outer convex and concave A filter screen 5 is placed in the tank 4, the output end of the waste water tank 1 is connected with a first pipeline 6, the first pipeline 6 is connected with a first water pump 7 and a first one-way valve 8, and the output end of the first pipeline 6 is connected with a hydraulic box 9. The hydraulic box 9 is connected with a mixing box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com