Segmented beam-erection pre-tensioning-method staggered symmetric tensioning prestressed reinforcing steel superposed assembly road and construction method thereof

A technology of symmetrical tensioning and prestressed tendons, applied in roads, roads, road construction reinforcements, etc., can solve the problems of less application of assembly construction technology, insufficient propulsion force, and poor load-bearing capacity of the road surface, etc., to increase the number of application cases , easy to promote construction, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

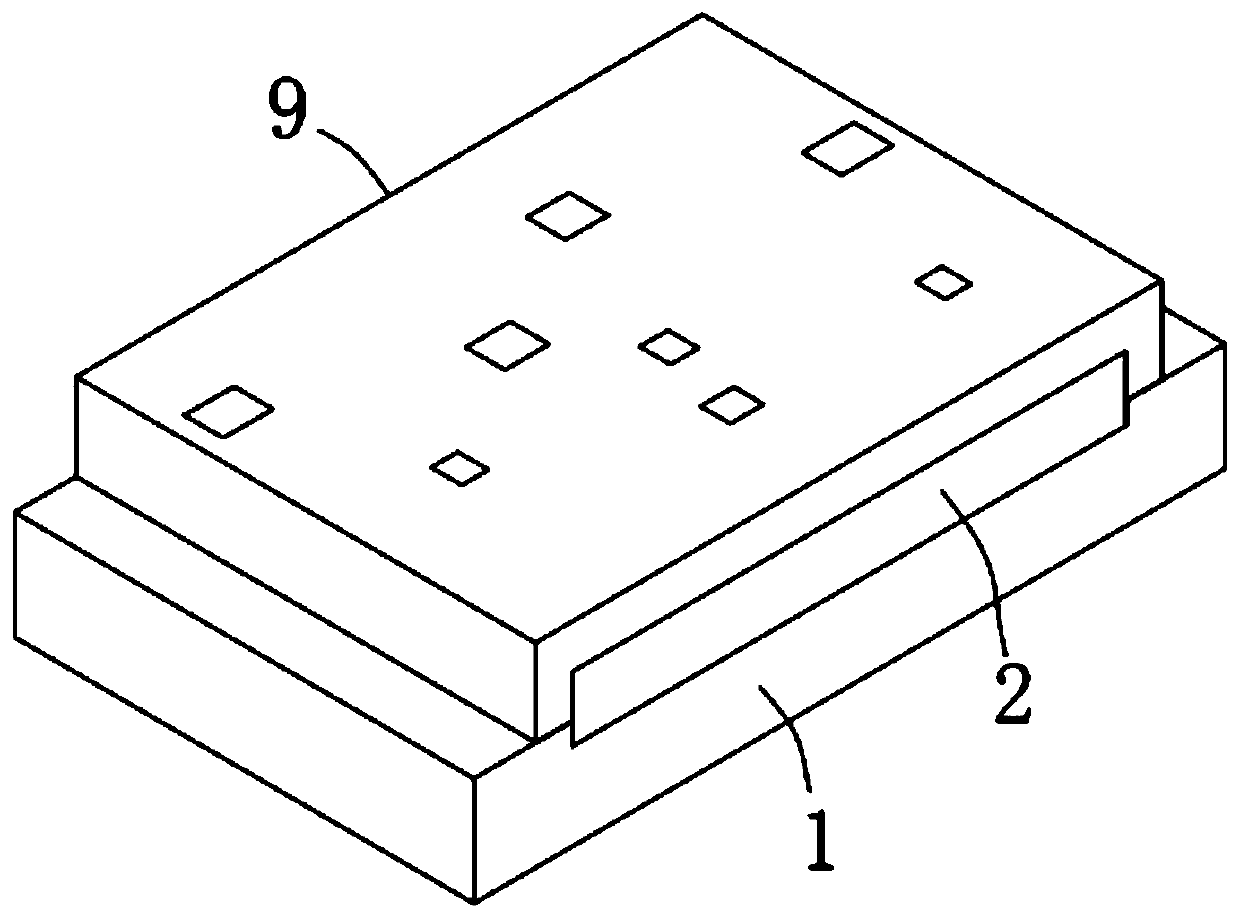

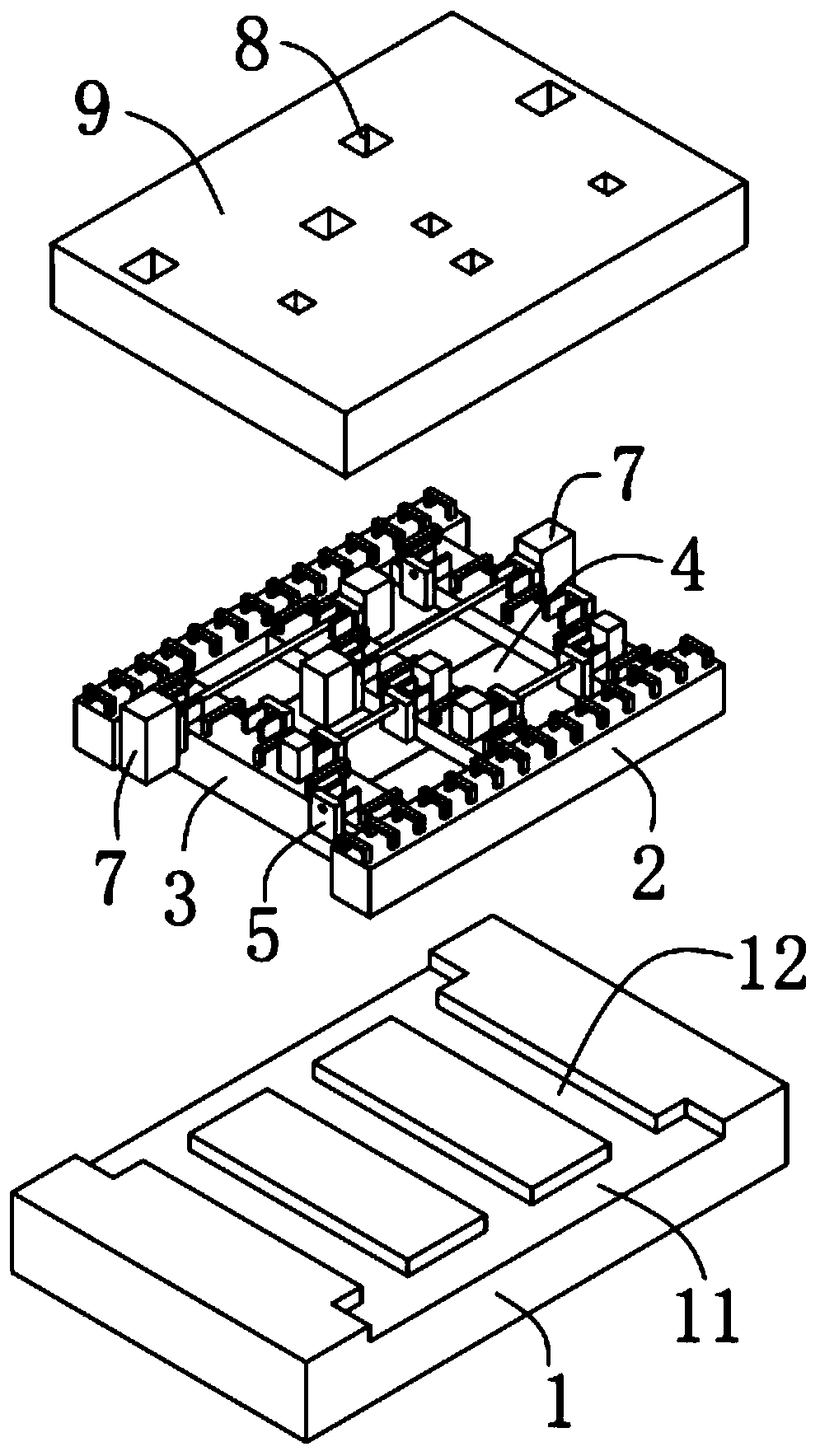

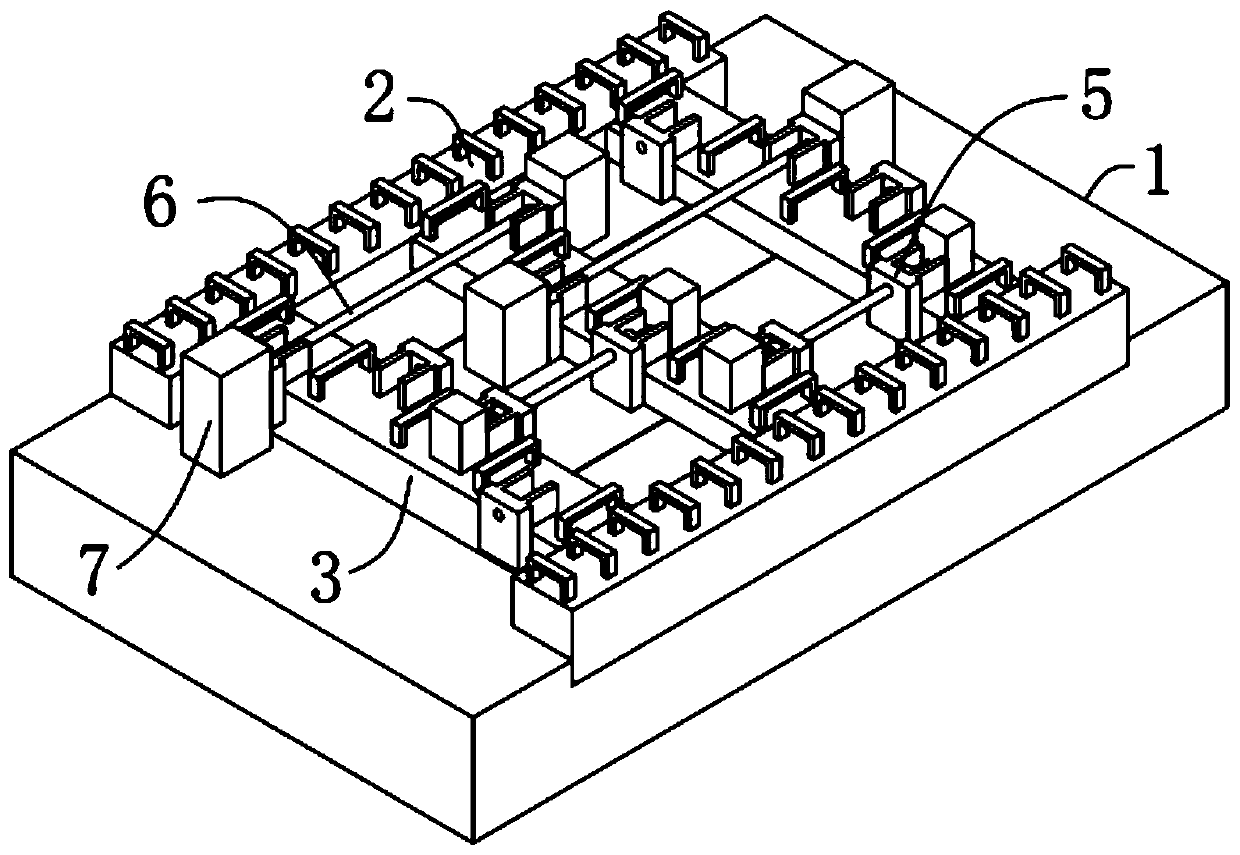

[0049] A pre-tensioned cross-symmetrical tensioned prestressed tendon laminated assembly road with segmented beams, such as Figure 1-7 As shown, it includes subgrade 1, longitudinal laminated beam 2, transverse laminated beam 3, laminated plate 4, steel anchor support 5, prestressed steel bar 6, anchor 10, foam block 7 and post-cast concrete surface 9, all Both sides of the upper part of the roadbed 1 are symmetrically provided with longitudinal laminated beam foundation grooves 11, and the upper part of the roadbed 1 is equidistantly provided with transverse laminated beam foundation grooves 12, and the horizontal laminated beam foundation grooves 12 are located on both sides. Between the foundation grooves 11 of the longitudinal laminated beams, and the foundation grooves 12 of the transverse laminated beams are arranged perpendicular to the foundation grooves 11 of the longitudinal laminated beams, the longitudinal laminated beams 2 are installed on the Inside the foundati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com