Hollow rock sample radial seepage test device and test method based on acoustic emission technique

An acoustic emission technology and a test device technology, which are applied in the field of radial seepage test devices for hollow rock samples, can solve the problem that the application of acoustic emission technology is not considered, the water inrush accident from the roof and floor of underground mines is difficult to prevent, and the structural instability of the rock mass cannot be revealed. Problems such as the internal mechanism of water inrush disaster of damaged roof and floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

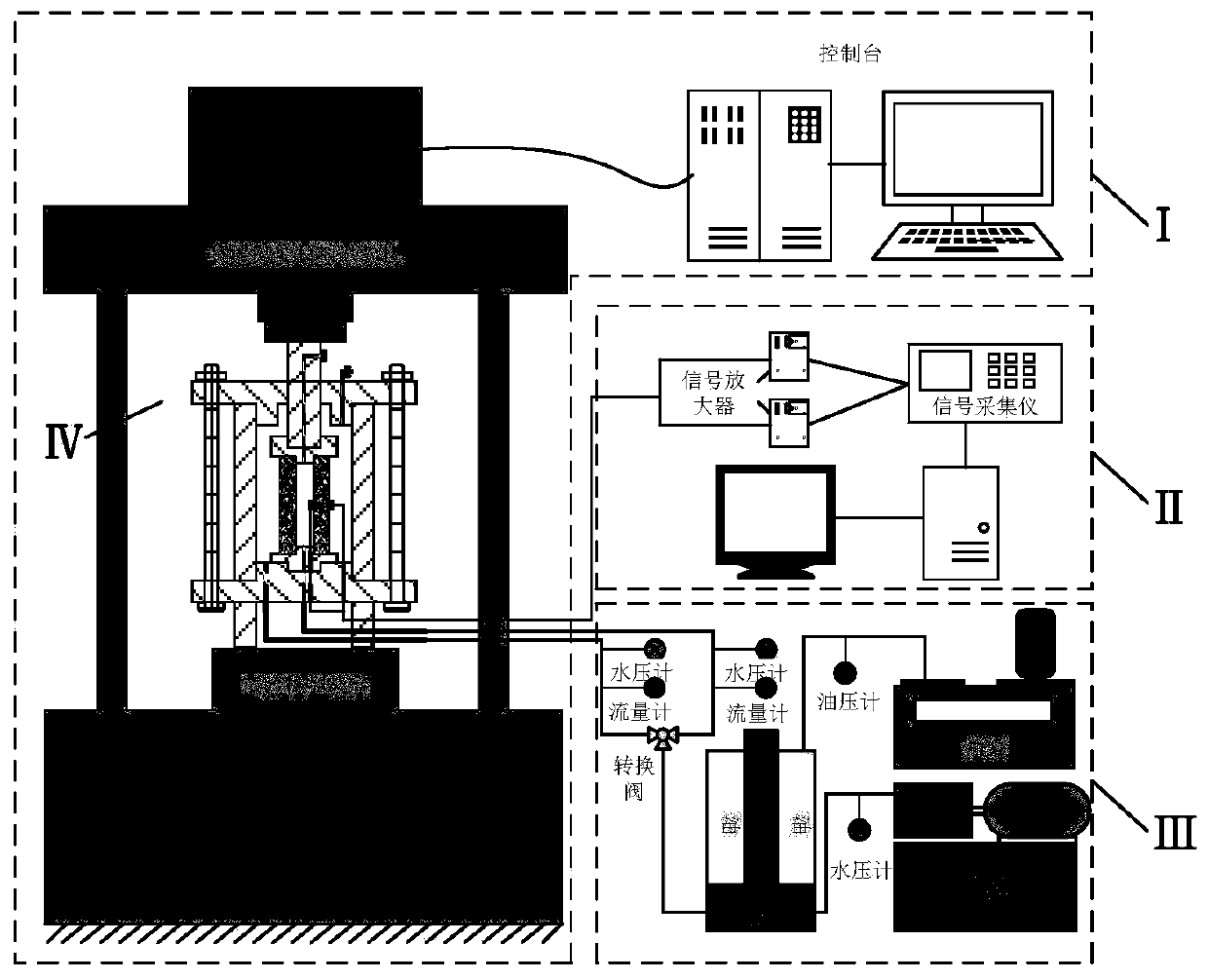

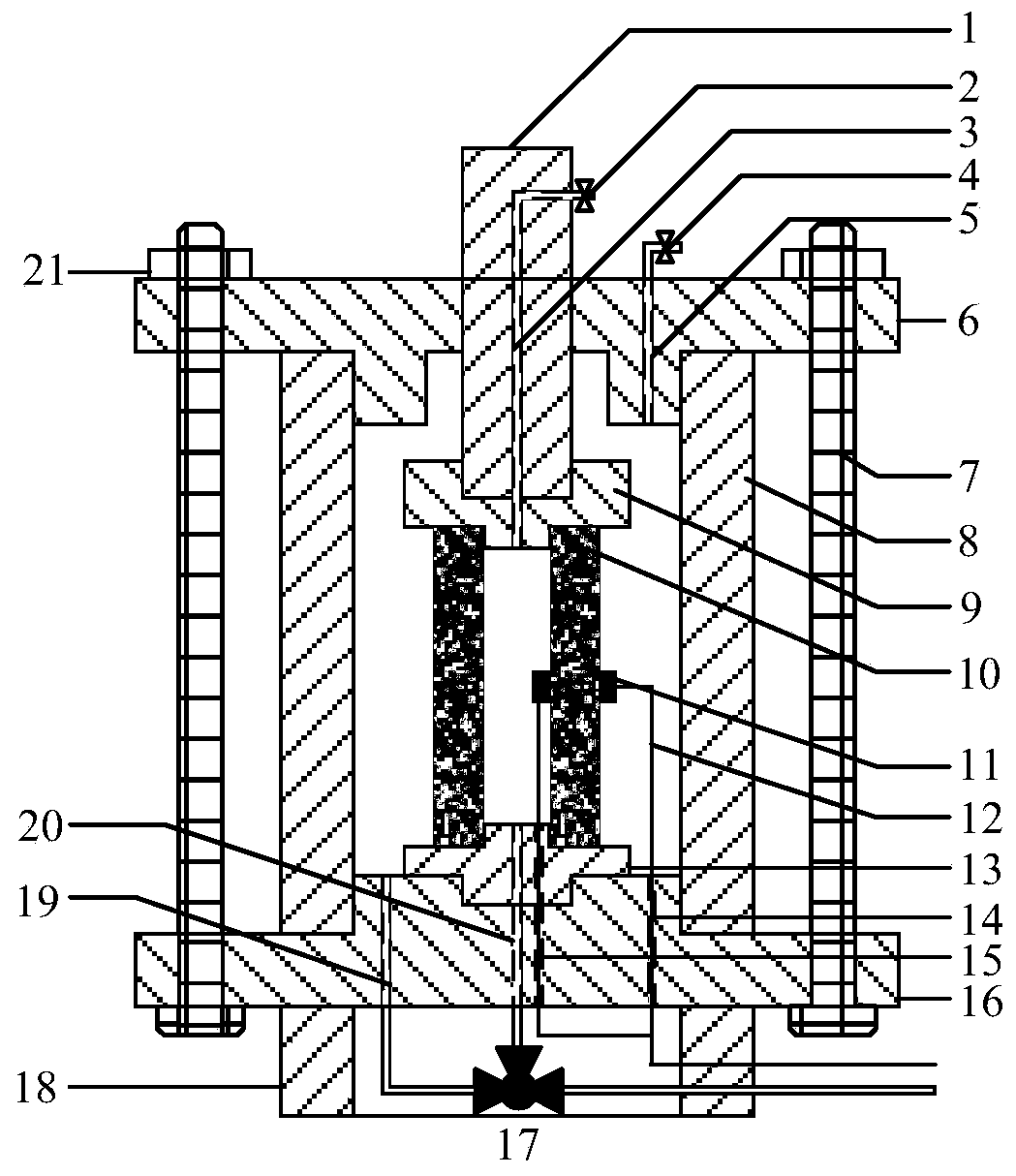

[0035] Such as Figure 1-2As shown, the hollow rock sample radial seepage test device based on acoustic emission technology of the present invention is mainly composed of axial loading system I, radial seepage system IV, hydraulic supply system III and acoustic emission system II. The loading system I includes a testing machine and a control console for controlling the testing machine. The radial seepage system IV is set on the loading table of the testing machine of the axial loading system I. The acoustic emission system II and the hydraulic supply system III are located in the radial direction. One side of the seepage system IV is connected to the radial seepage system IV through signal lines and pipelines respectively; the acoustic emission system II includes a signal amplifier, a signal collector and a computer connected to the probe 11 in turn b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com