Tobacco strip aqueous extract absorbance determining and alcoholization process determining method

An absorbance and water extract technology, which is used in the measurement of color/spectral characteristics and the preparation of test samples, can solve the inconsistency of the principles of black tea fermentation and tobacco alcoholization, cannot be used to judge the quality of tobacco alcoholization, and cannot reflect the sensory evaluation of tobacco leaves. Absorption quality and other issues, to achieve the effect of less equipment involved, less error, and simple measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

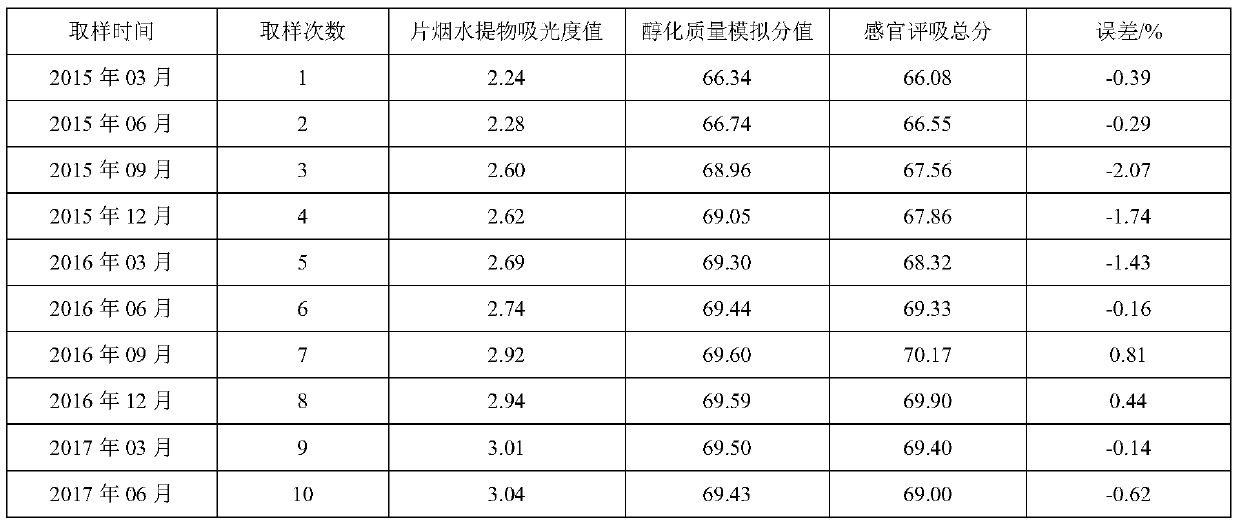

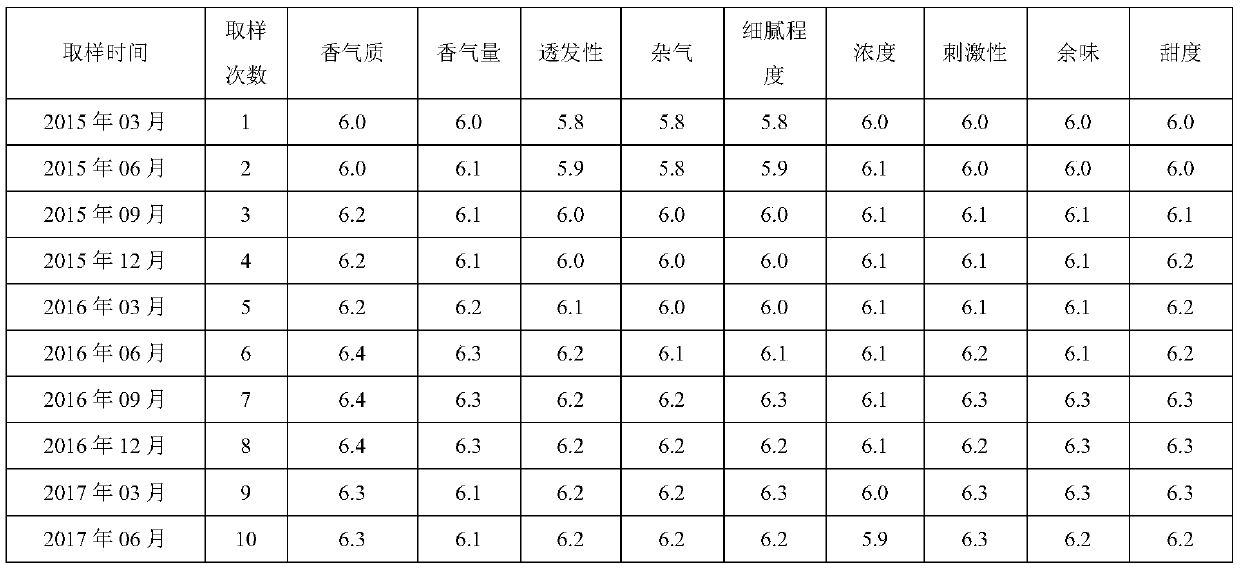

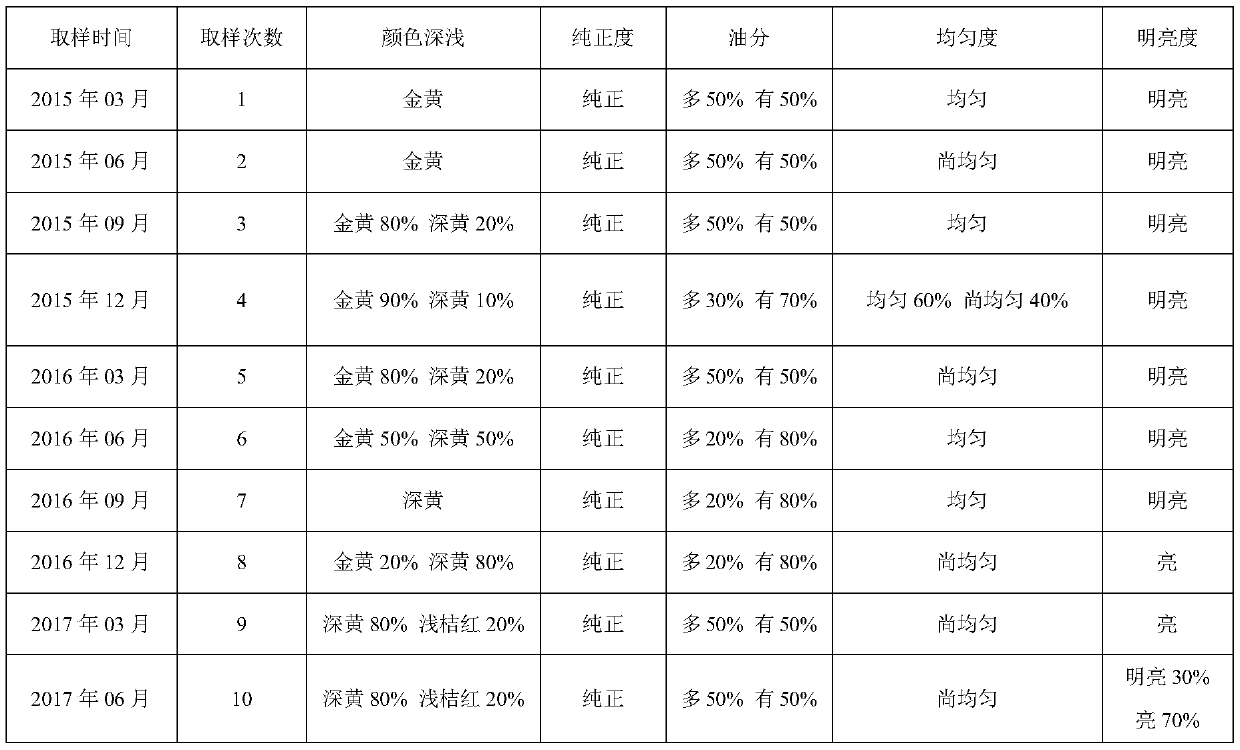

[0017] Using a method for detecting the absorbance value of the water extract of tobacco slices and judging the quality of alcoholization in the present invention, the Yunnan Pu'er Mojiang C3F grade tobacco slices that were put into storage in December 2014 were detected and quality judged. 2210 boxes, three boxes of samples were randomly selected, each box was extracted by five-point sampling method, 0.5kg sample was selected from a single box, 1.0g sample was weighed after low-temperature crushing, and the absorbance value of the water extract was measured for the sheet tobacco sample according to the detection steps, and The tobacco samples were rolled and smoked. Afterwards, 3 boxes of samples were selected every 3 months, and the tobacco samples were taken from them, and the tobacco samples of this grade were tracked and sampled, and the absorbance value of the water extract was measured and the rolling evaluation was carried out. A total of 10 samples were taken and measu...

Embodiment 2

[0032] Using the method for detecting the absorbance value of a kind of tobacco water extract and judging the alcoholization quality in the present invention, the C2F grade tobacco of Guizhou Qianxinan, which was put into storage in 2014, was detected and quality judged. When this grade of tobacco was put into storage in 2014, there was 1520 boxes, three boxes of samples were randomly selected, each box was extracted by five-point sampling method, 0.5kg sample was selected from a single box, 0.5g sample was weighed after low-temperature crushing, 15ml pure water was added, and filtered with a needle filter after standing for 30 minutes. The absorbance value of the filtrate was measured, and the tobacco samples were rolled and smoked. After that, the tobacco samples were taken every 3 months, followed by sampling of the grade tobacco samples, and the absorbance value of the water extract was measured and the rolling evaluation was carried out. A total of 11 samples were taken an...

Embodiment 3

[0042] Using a method for detecting the absorbance value of the water extract of tobacco slices and judging the quality of alcoholization in the present invention, the B2F grade tobacco slices of Huidong, Liangshan, Sichuan, which were put into storage in December 2015, were detected and quality judged. There are 1322 boxes, three boxes of samples are randomly selected, and each box is extracted by five-point sampling method. A 0.5kg sample is selected from a single box, and 1.0g sample is weighed after low-temperature crushing. Tobacco samples were rolled and smoked. Afterwards, the tobacco samples were taken every 3 months, and the samples of this grade of tobacco were tracked and sampled, and the absorbance value of the water extract was measured and the rolling evaluation was carried out. A total of 11 samples were taken and measured. Sichuan Liangshan Huidong B2F grade tobacco See Table 9 for the absorbance value of the water extract and the simulated score of the tobacco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com