Metallic workpiece surface defect recognition method and device based on machine vision

A technology for identifying metal workpieces and defects, which is applied in the direction of measuring devices, optical testing defects/defects, instruments, etc., can solve the problems of gray analysis methods such as limitations, inconspicuousness, and inconspicuous defect characteristics, so as to avoid labor-intensive, The effect of reducing detection cost and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

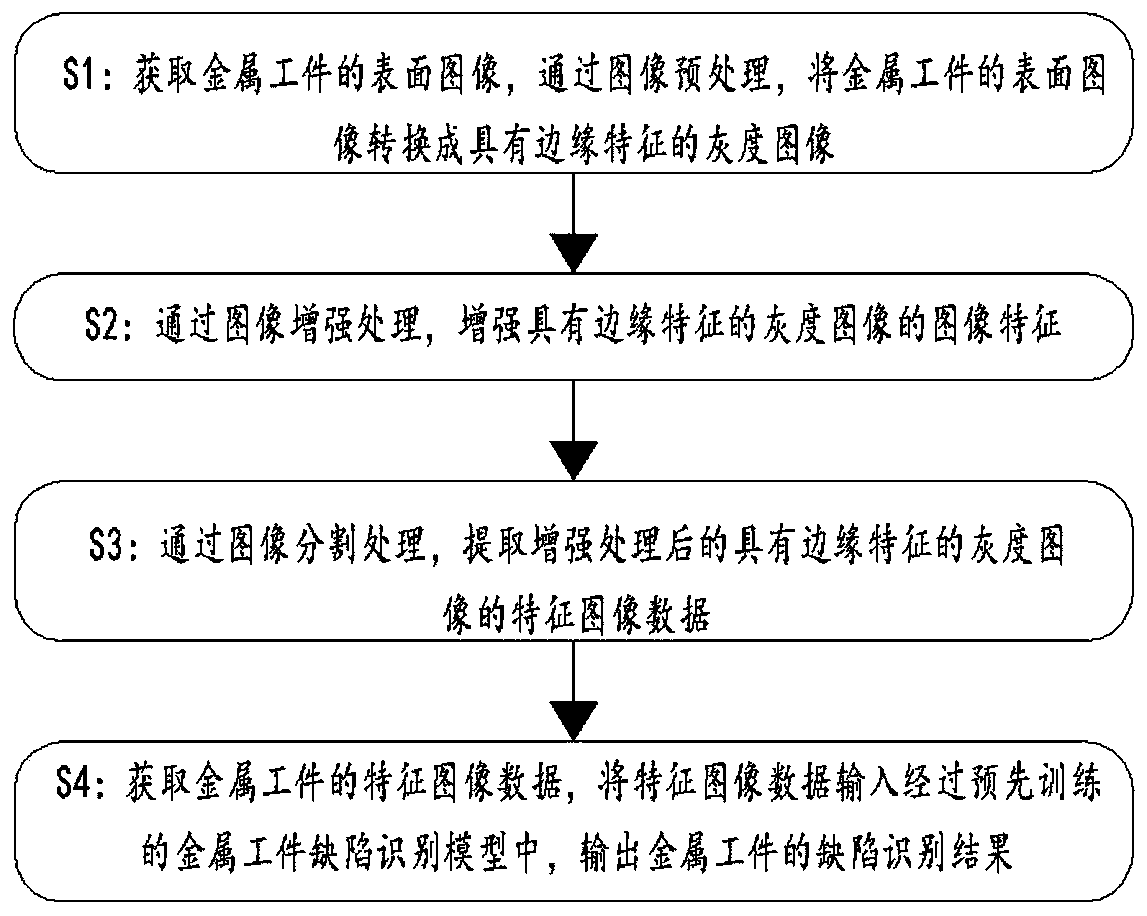

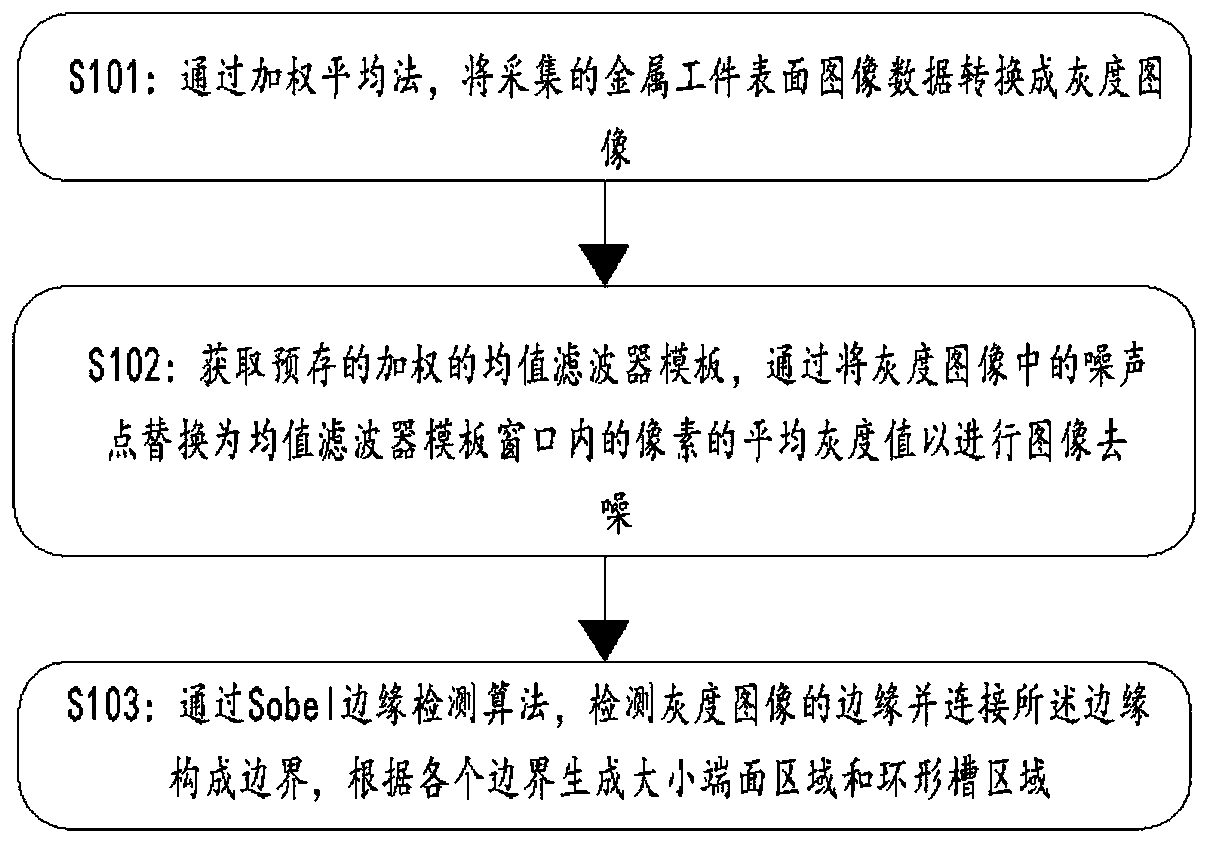

[0059] Such as figure 1 As shown, a machine vision-based metal workpiece surface defect recognition method includes the following steps:

[0060] S1: Obtain the surface image of the metal workpiece, and convert the surface image of the metal workpiece into a grayscale image with edge features through image preprocessing.

[0061] S2: Through image enhancement processing, image features of the preprocessed grayscale image with edge features are enhanced.

[0062] S3: Extract feature image data of the enhanced grayscale image with edge features through image segmentation processing.

[0063] S4: Obtain the feature image data of the metal workpiece, input the feature image data into the pre-trained metal workpiece defect recognition model, and output the defect recognition result of the metal workpiece.

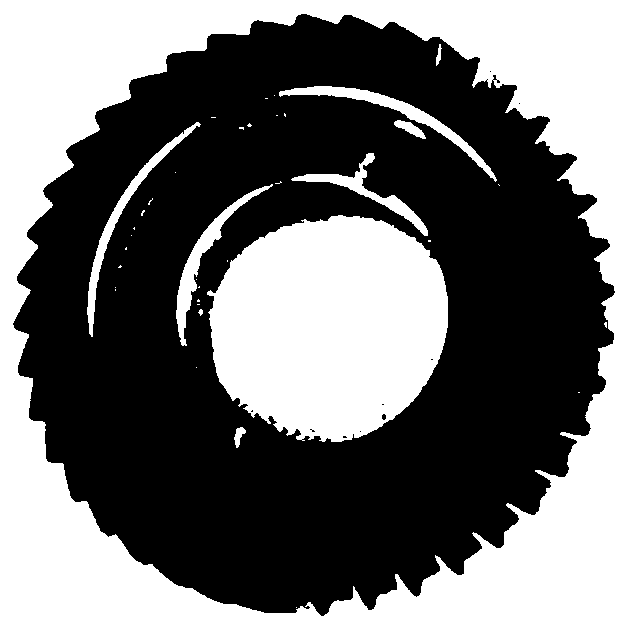

[0064] Specifically, this embodiment takes a gear workpiece as an example, and continues to introduce a machine vision-based method for identifying surface defects on a metal ...

Embodiment 2

[0094] This embodiment discloses a device for identifying surface defects of a metal workpiece 101 based on machine vision.

[0095] Such as Figure 9 Shown: the metal workpiece 101 surface defect recognition device based on machine vision includes

[0096] The manipulator 1 is used for clamping a metal workpiece 101 .

[0097] The alarm 5 is used for sending an alarm signal.

[0098] The lifting bin 2 is used to place metal workpieces 101, and the lifting bin 2 is divided into two parts: a defective parts bin and a normal parts bin by a partition.

[0099] The image acquisition device is used to acquire the surface image of the metal workpiece 101 . The image acquisition device includes an industrial camera 3 and an adjustable bracket 4 , wherein the industrial camera 3 is fixed on the adjustable bracket 4 , and the adjustable bracket 4 is placed directly opposite the manipulator 1 .

[0100] The central processing module is used to obtain the surface image of the metal w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com