Intelligent rapid impurity analyzer

An impurity analysis and rapid technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of detection efficiency, low accuracy, no major breakthrough in structure, impurity detection, etc., to achieve accurate and reliable detection results, improved detection efficiency, cotton The effect of shortening the separation time of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

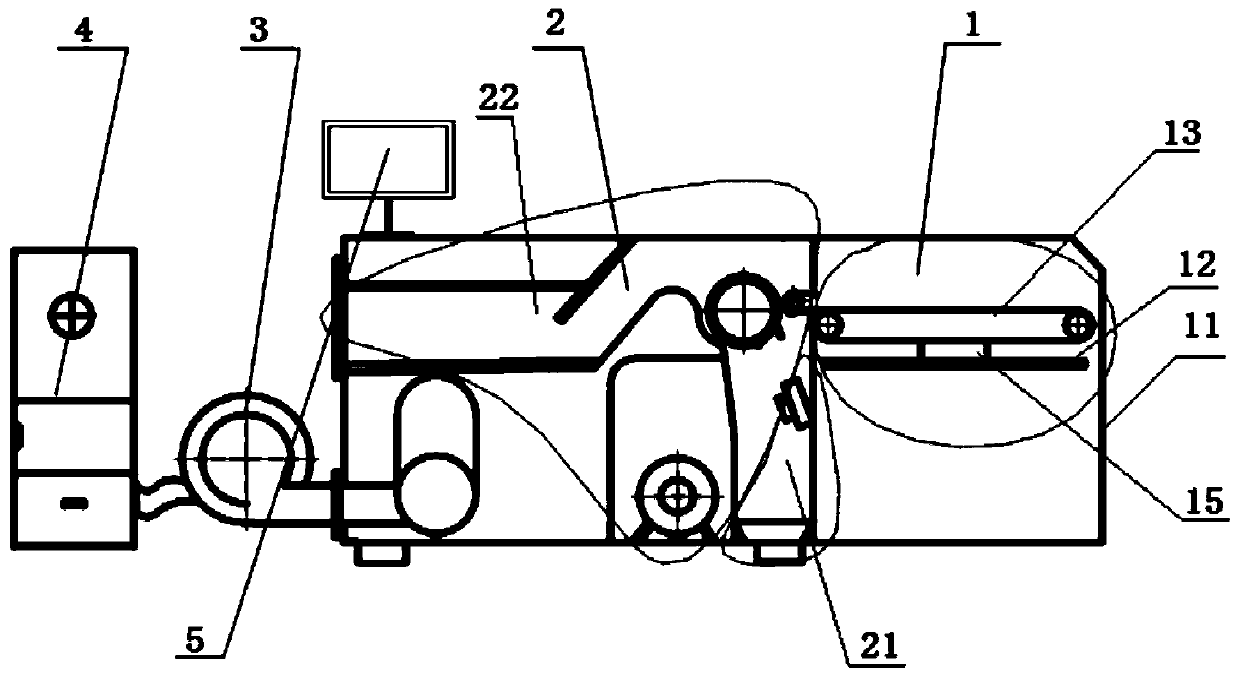

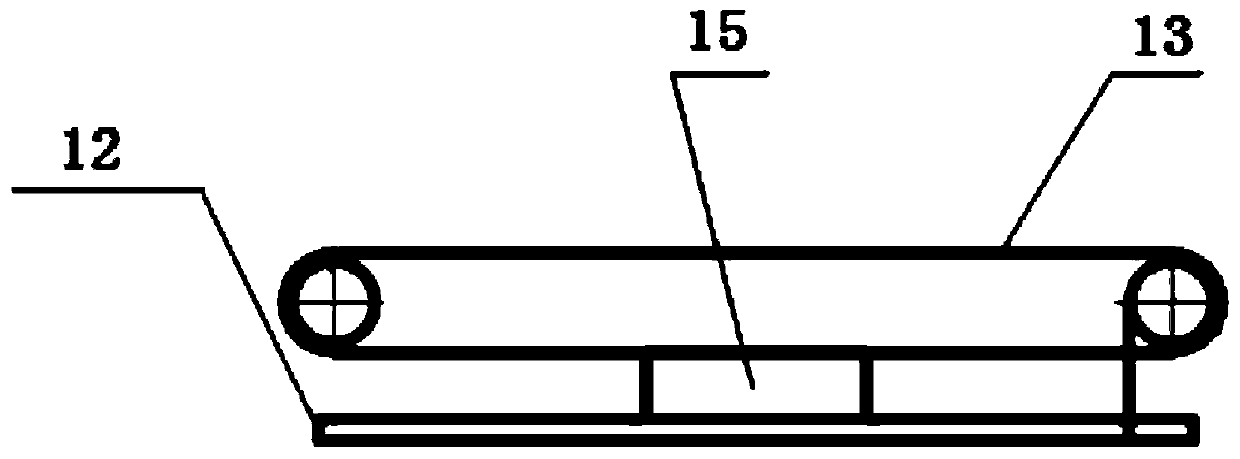

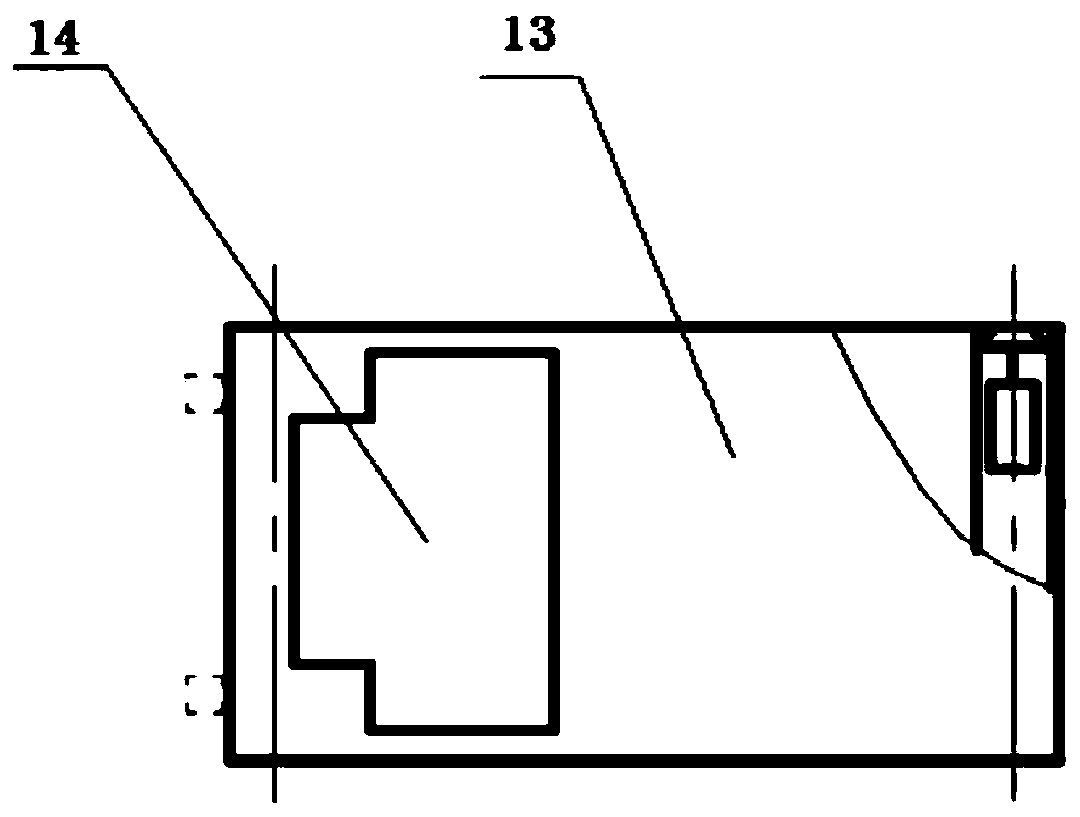

[0041] Such as figure 1 As shown, the present invention provides an intelligent fast impurity analyzer, which includes an automatic weighing and conveying system 1; a cotton waste separation system 2, which is arranged downstream of the automatic weighing and conveying system 1, for receiving from the automatic weighing and conveying system 1 the cotton sample sent, and the cotton sample is carried out to the cotton miscellaneous separation and collection process, the bottom of the impurity collection chamber 21 in the cotton miscellaneous separation system 2 is provided with an automatic weighing device for impurities (not shown in the figure); fan bell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com