Brushless direct current motor DSP logical control program design method based on Petri net

A brushed DC motor and logic control technology, applied in the field of DSP logic control of brushless DC motors, can solve the problems of difficulty in avoiding program logic errors, cumbersome DSP logic control program design and debugging, and difficulty in obtaining reliable logic control programs, etc. Achieve the effect of avoiding logical errors and easy analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

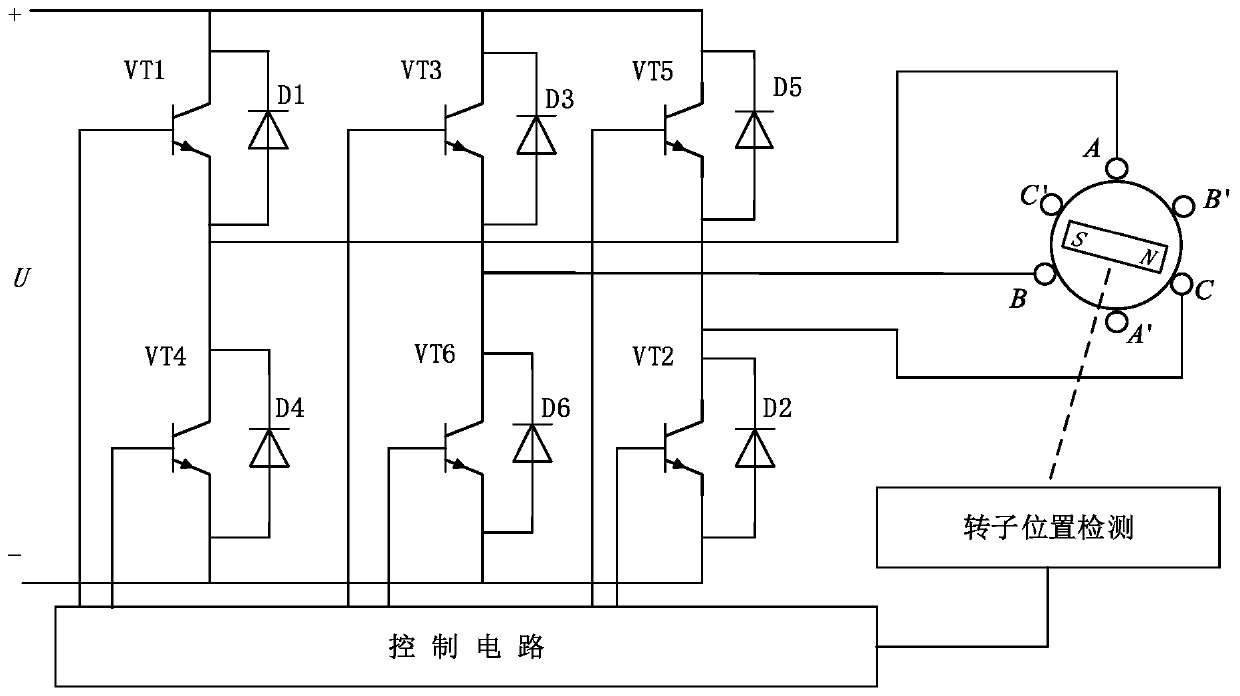

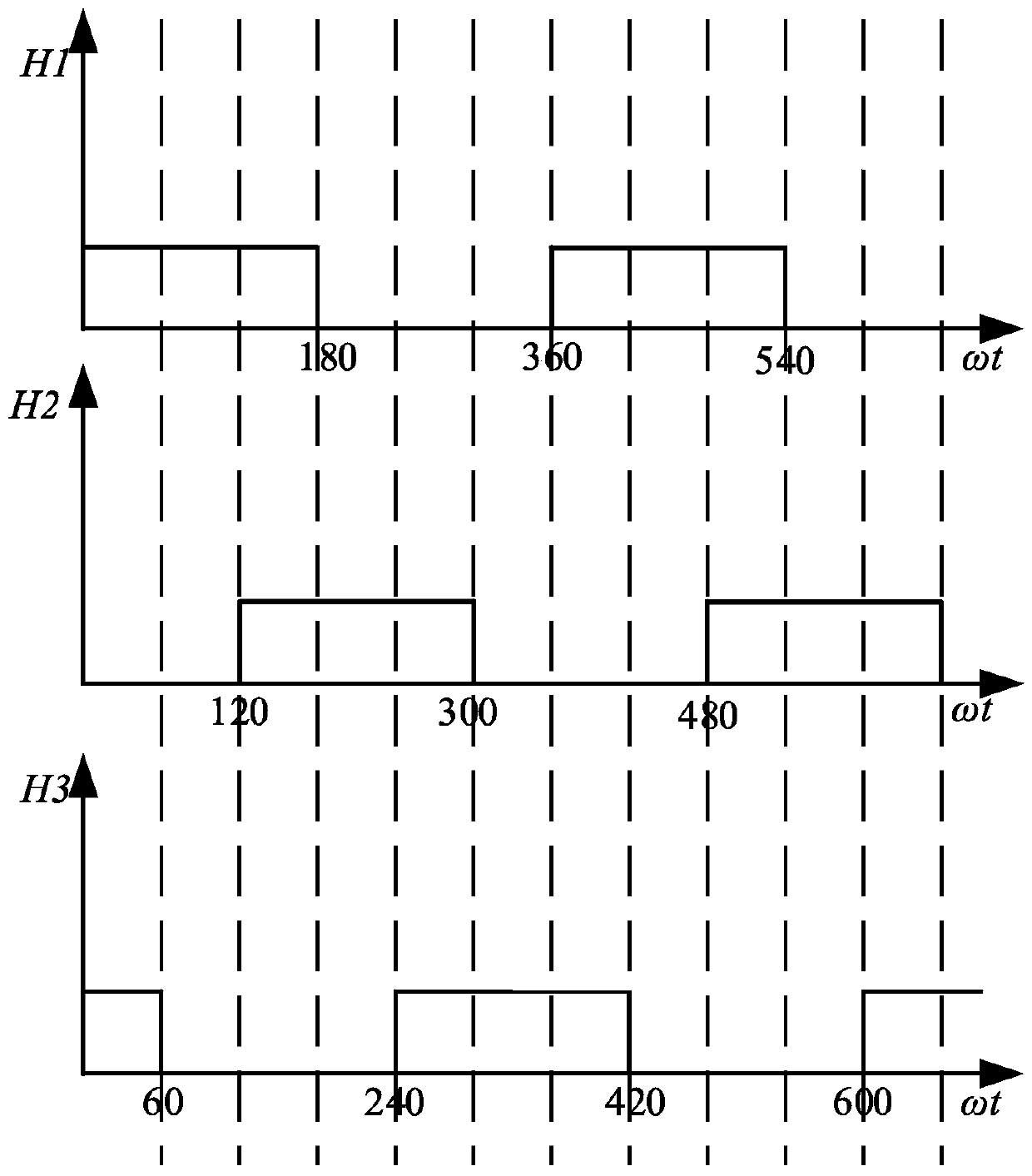

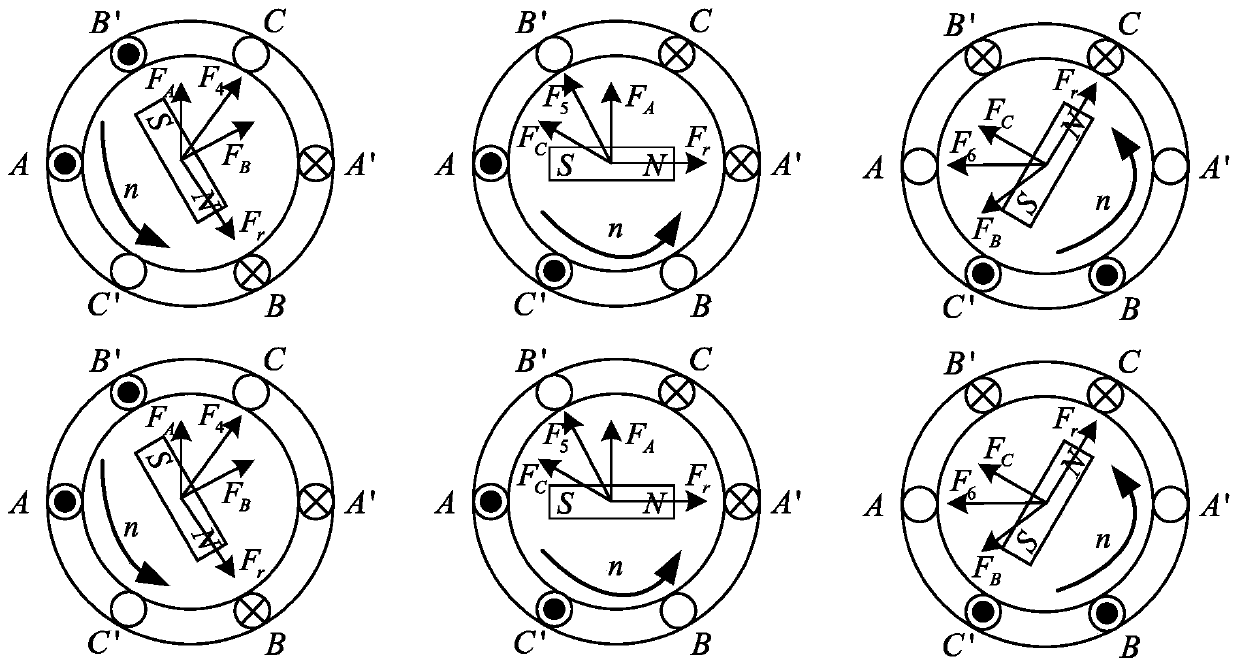

[0052] Such as figure 1 As shown, in the brushless DC motor drive circuit of this embodiment, the stator windings of the motor are connected in star form, and the inverter adopts a three-phase full-bridge inverter circuit, and the power supply mode is two-two conduction. The rotor position is detected by the Hall sensor, the pulse width signal output by the sensor is 180° electrical angle, and the phase difference of the three Hall signal outputs is 120°, such as figure 2 , image 3 shown. The controller processes the position signal to output commutation information, and drives the VT on the three bridge arms of the inverter circuit 1 ~VT 6 The relationship between power tube, Hall sensor status and commutation is shown in the following table:

[0053]

[0054]

[0055] The design method of the described brushless DC motor DSP logic control program based on Petri net, comprises the following parts:

[0056] 1) Establish the Petri net model of the Hall sensor

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com