Catenary dropper defect detection model training method and defect detection method

A defect detection and model training technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve the problems of low detection efficiency of catenary hanging string defects, easy to miss detection, etc. Sticky and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Example of training method for catenary suspension string defect detection model

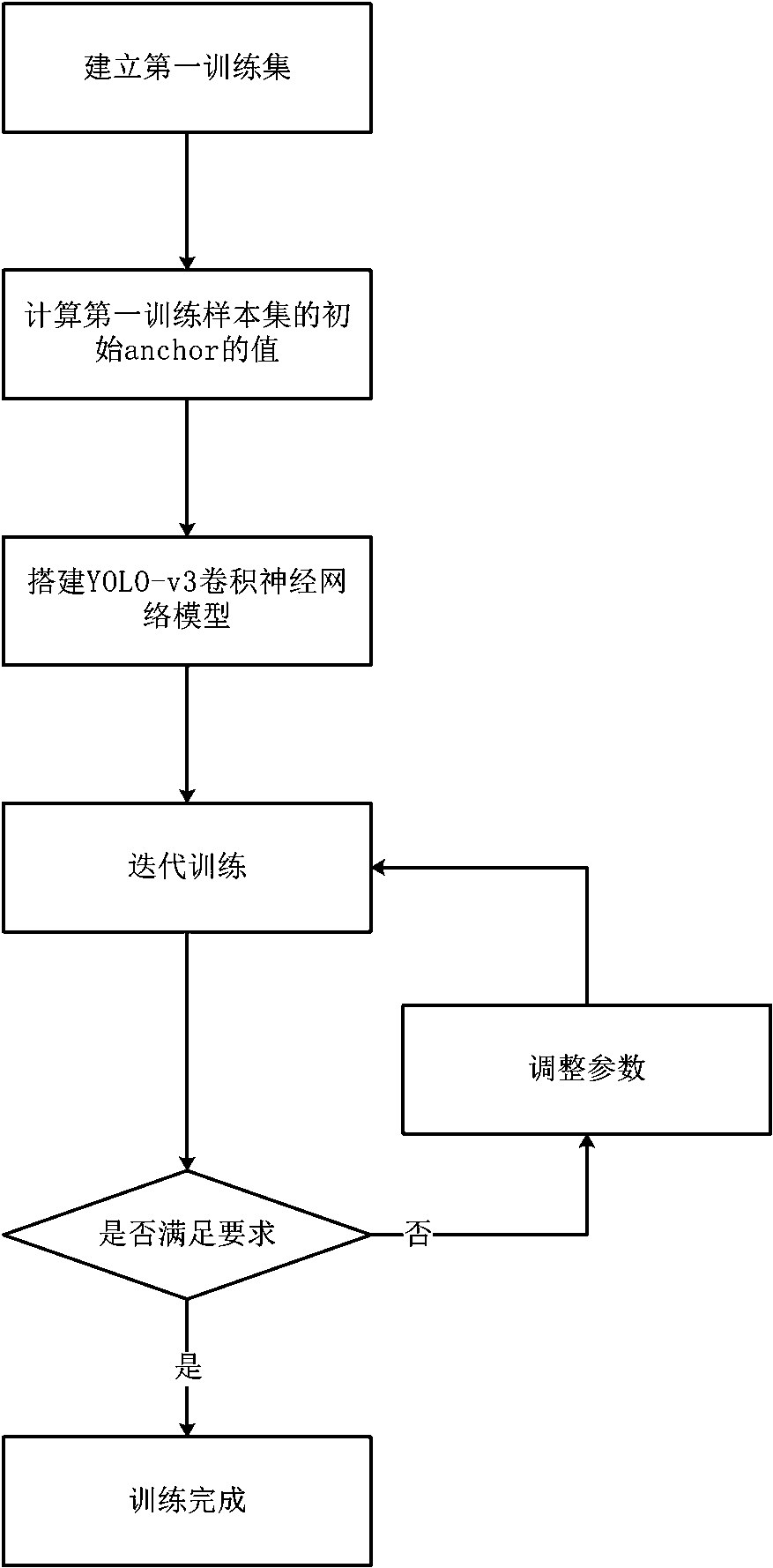

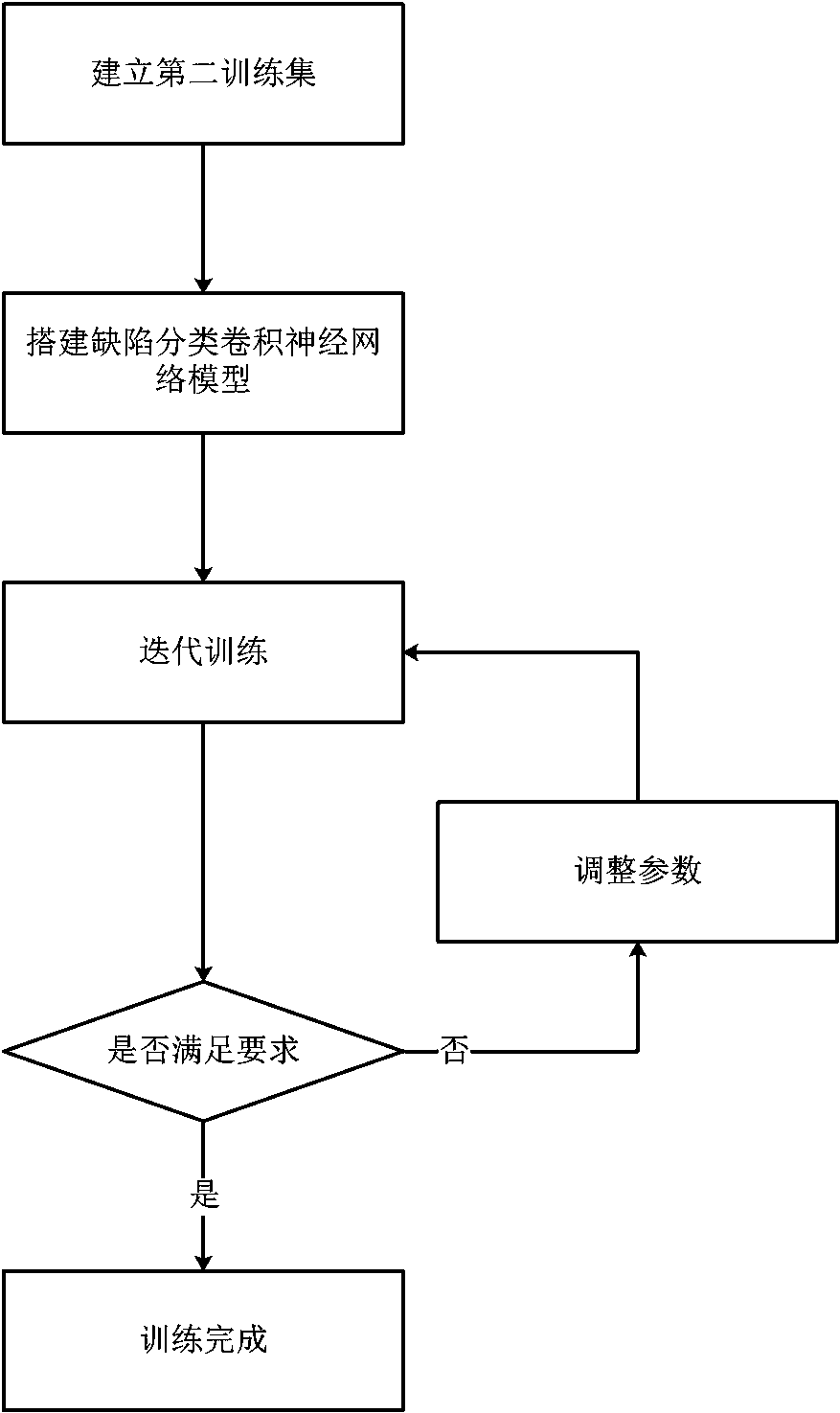

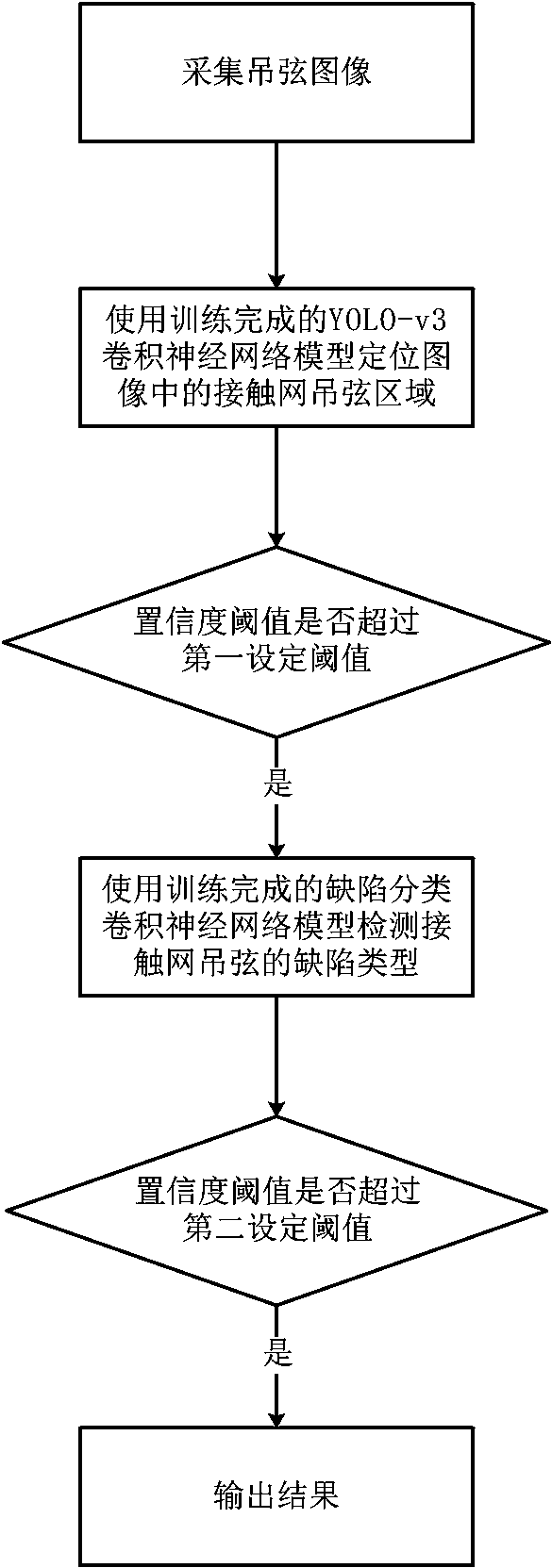

[0044] Such as figure 1 , figure 2 Shown is the training flowchart of the YOLO-v3 convolutional neural network model and the defect classification convolutional neural network model in this embodiment, and the specific steps are as follows.

[0045] Step 1: sort out the catenary hanging string images collected by the previous equipment inspection trains, prepare corresponding samples to build a sample set according to the main components of the catenary hanging string, expand the sample diversity through data augmentation, and calibrate the samples.

[0046] Among them, the sample size is expanded by means of data augmentation, so that the sample size of each type of sample set is not less than 40,000; the image labeling tool labelImg is used to label the hanging string stay wire, bearing cable clip and contact wire clip.

[0047]Step 2: Determine the convolutional neural network struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com