Rotor-rotor shaft-assembly with material matched connection

A rotor shaft and rotor technology, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of impractical assembly, reduced torque transmission, difficult assembly, etc., and achieve cost-effective and reliable torque transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

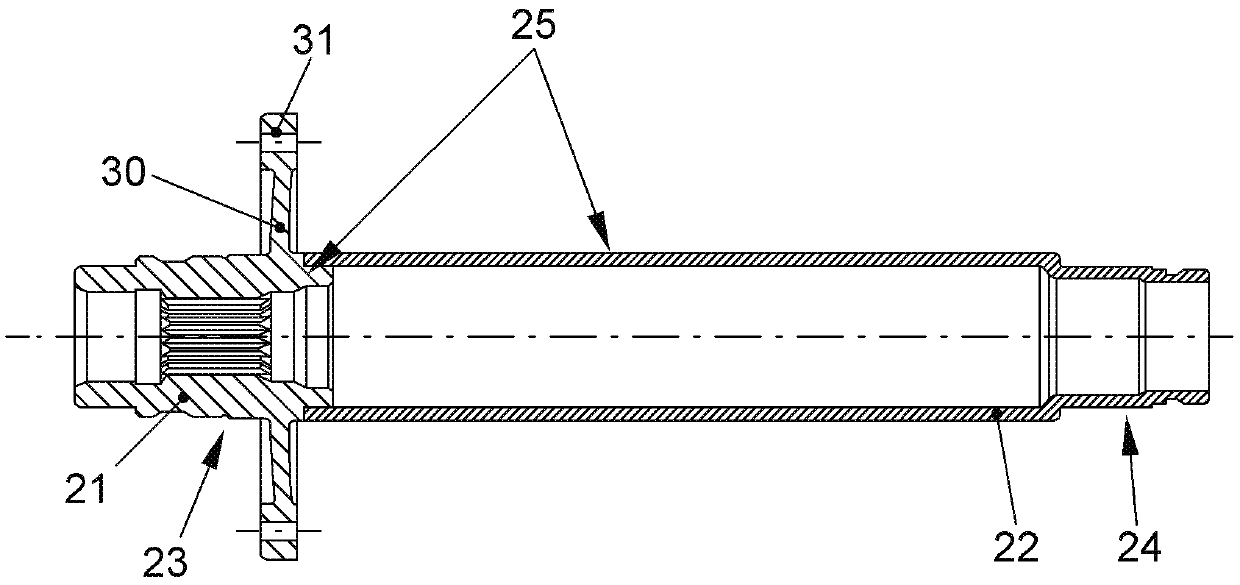

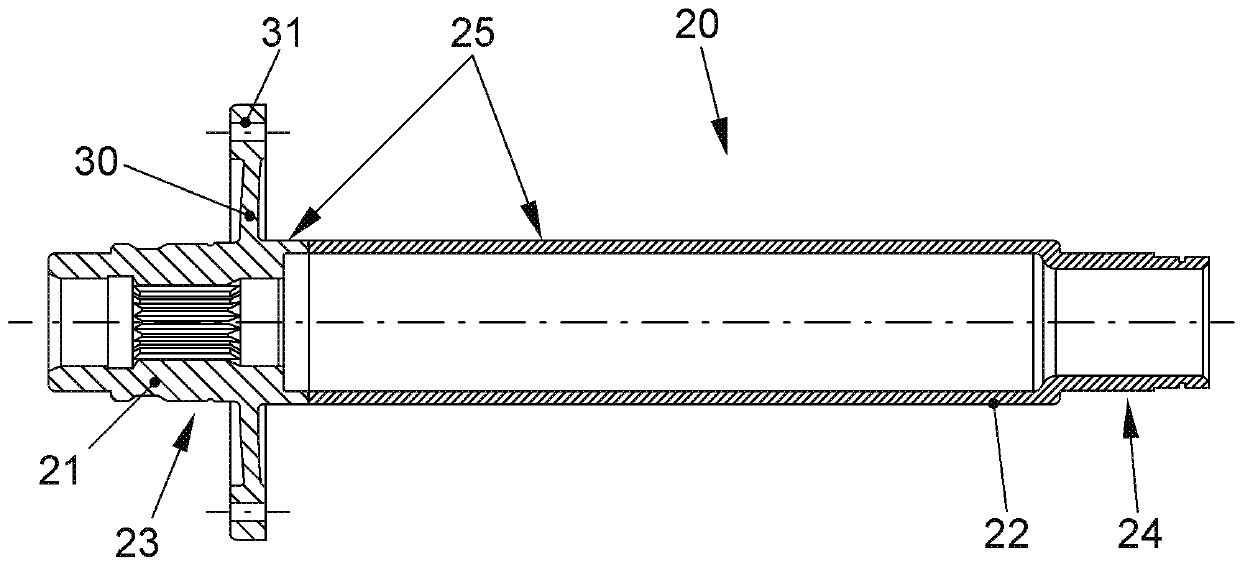

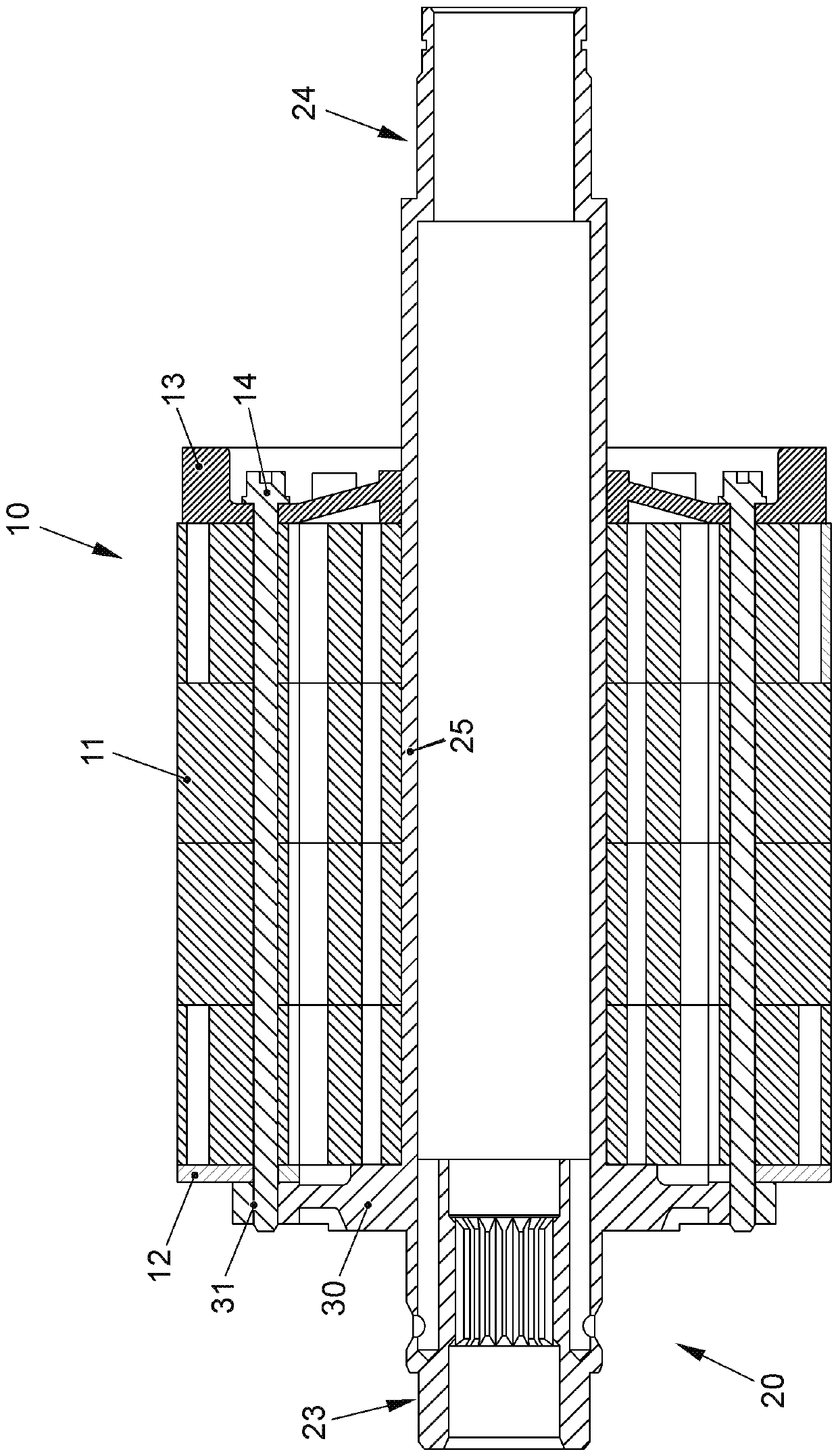

[0037] figure 1 and 2 show an embodiment of a rotor-rotor shaft assembly according to the invention for an electric machine, for example for a motor vehicle, for example for an electric vehicle and / or a hybrid vehicle.

[0038] figure 1 2 and 2 show that the rotor-rotor shaft assembly has a rotor 10 , a rotor shaft 20 and a rotor flange 30 for fastening the rotor 10 on the rotor shaft 20 . In this case, a material-fit connection is formed between the rotor shaft 20 and the rotor flange 30 , that is to say the rotor flange 30 is formed in one piece with a part of the rotor shaft.

[0039] The rotor 10 here has a plurality of rotor laminations 11 and a spacer disk 12 arranged between the rotor laminations 11 and the rotor flange 30 , in particular for magnetically decoupling the rotor laminations 11 from the rotor flange 30 . The rotor 10 also has tensioning and / or balancing discs 13 and tensioning screws 14 . Here, the spacer disk 12 and the rotor disk pack 11 are arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com