An integrated packaging structure for dual motor controllers

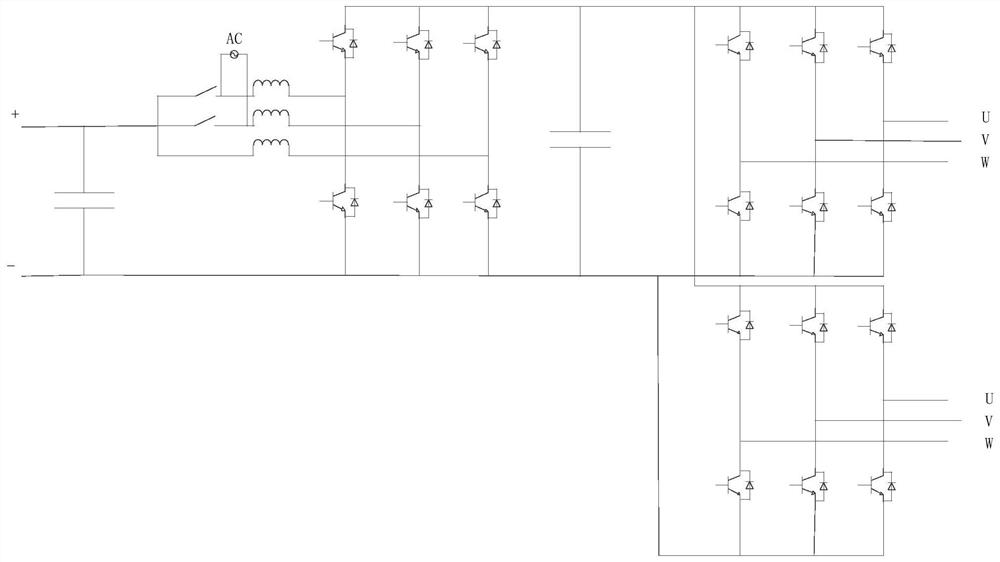

An integrated packaging and controller technology, applied in the direction of controlling multiple AC motors, output power conversion devices, and transforming equipment structural components, etc., can solve the problems of low space utilization of the whole machine, complex internal connections, and many connecting devices , to achieve the effect of improving space utilization and integration, improving heat dissipation efficiency, and reducing heat dissipation thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

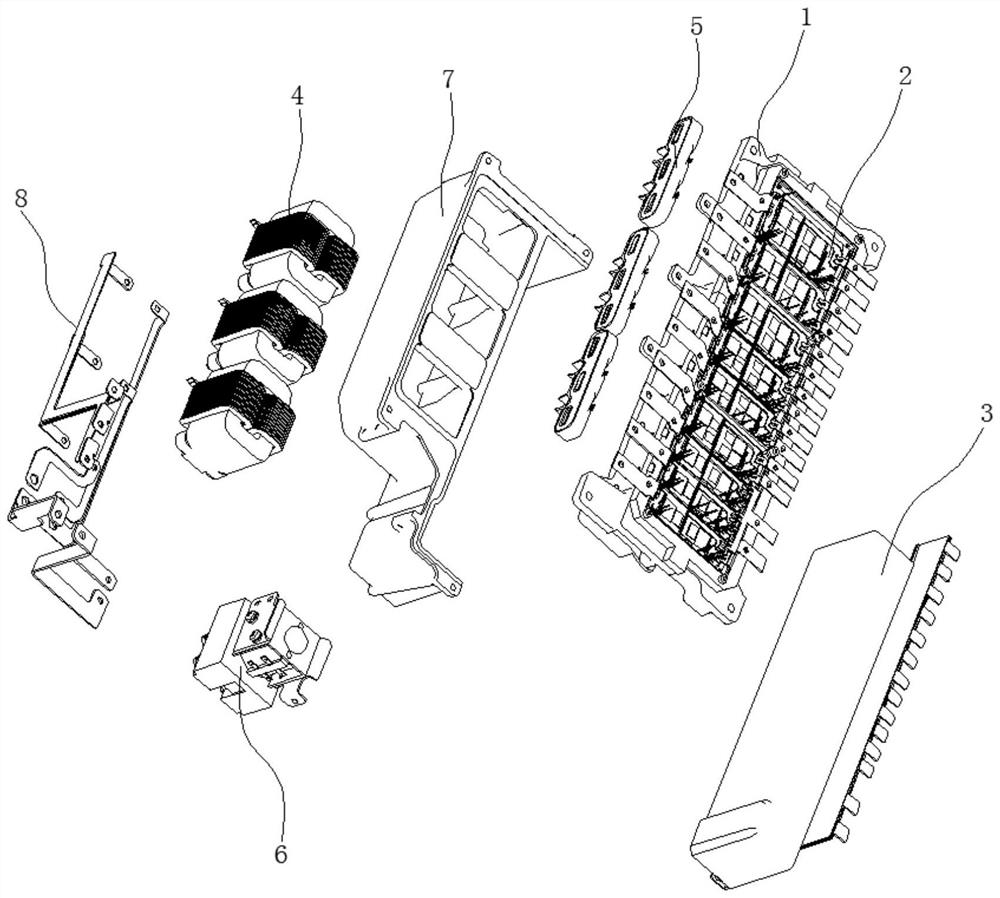

[0023] Such as figure 2 As shown, the integrated packaging structure of the dual-motor controller of the present invention includes a water-cooled plate 1, a power module 2, a film capacitor 3, a Boost inductor group 4, a three-phase current sensor 5, a relay 6, a potting box 7 and a connecting copper bar 8. The power module 2 and the three-phase current sensor 5 are fixed on one side of the water-cooled plate 1, and the film capacitor 3, Boost inductor group 4 and relay 6 are arranged on the other side; the potting box 7 is fixedly connected to the water-cooled plate 1 to form a potting The glue cavity, the film capacitor 3 and the Boost inductor group 4 are sealed and fixed in the glue cavity.

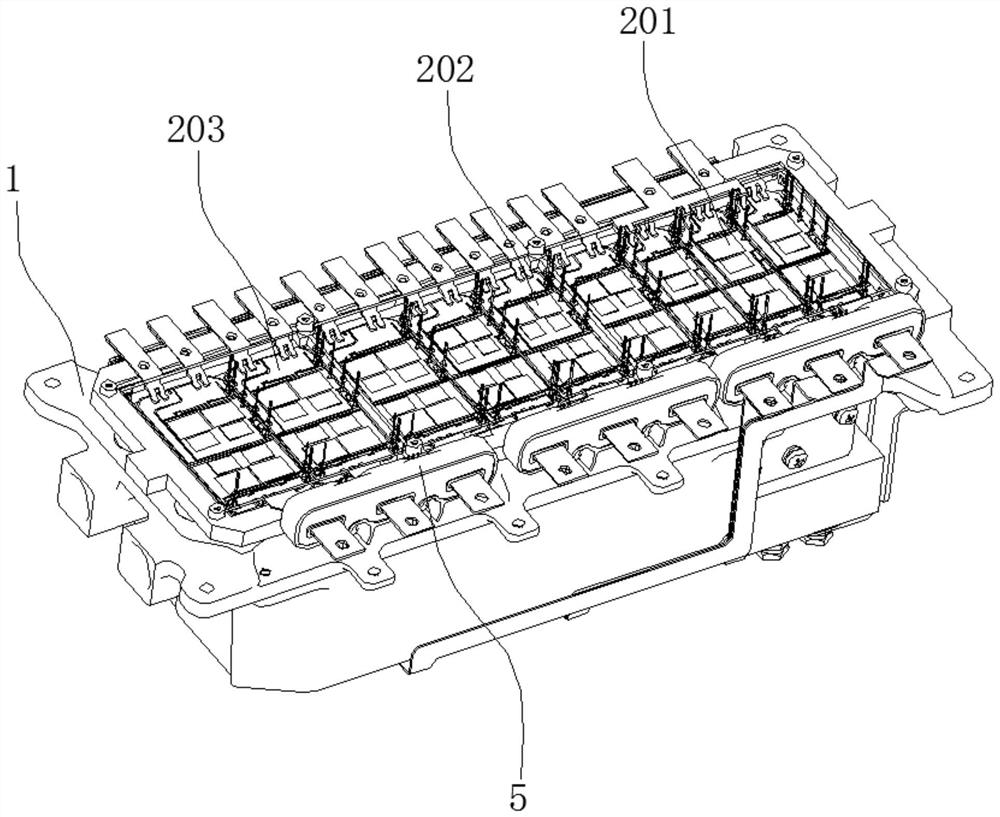

[0024] Such as image 3 As shown, the power module 2 includes a Boost converter unit 201 , a generator controller unit 202 and a motor controller unit 203 , and the wafer components of each unit of the power module 2 are welded to the water cooling plate 1 . The electrodes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com