Side-water-outlet and peripheral-transmission mud scraper and mud scraping method

A technology of peripheral transmission and mud scraper, applied in the direction of separation method, chemical instrument and method, feeding/discharging device of settling tank, etc., can solve the problem of low sedimentation efficiency, ensure the deposition effect, improve the deposition effect, The effect of extending the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

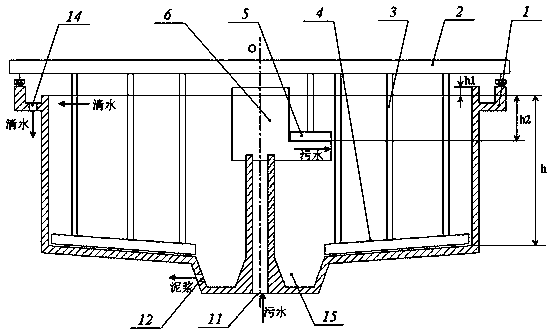

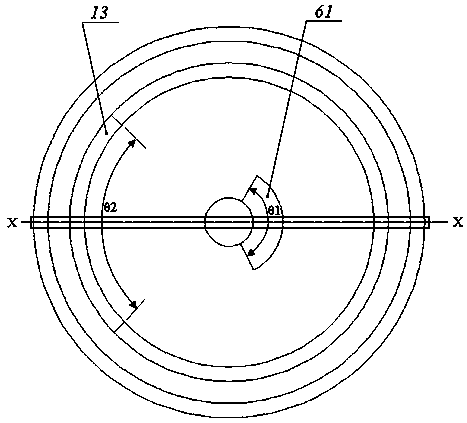

[0015] In this example, the diameter of the sedimentation tank 1 is 25m, and the depth is 3.5m. The height h1 of the fan-shaped clear water outlet 13 of the sedimentation tank 1 is 20cm, and the fan-shaped included angle of the fan-shaped clear water outlet 13 is 90 degrees. The angle is 120 degrees, the distance between the upper end of the fan-shaped sewage outlet 61 and the upper end of the sedimentation tank 1 is 0.85m, the height of the fan-shaped sewage outlet 61 is 60cm, and the sewage flow rate is 380 m 3 / hr, the speed of the mud scraper is 0.18r / min. After testing, the sludge concentration is 14 mg / l after being treated by the side water outlet mud scraper of the present invention, while the sludge concentration in the clear water of the traditional circumferential water outlet mud scraper is 22 mg / l, which greatly improves the sludge concentration. deposition effect.

Embodiment 2

[0017] In this example, the diameter of the sedimentation tank 1 is 36m, and the depth is 4m. The height h1 of the fan-shaped clear water outlet 13 of the sedimentation tank 1 is 25cm, and the fan-shaped included angle of the fan-shaped clear water outlet 13 is 120 degrees, and the fan-shaped included angle of the fan-shaped sewage outlet 61 The distance between the upper end of the fan-shaped sewage outlet 61 and the upper end of the sedimentation tank 1 is 1m, the height of the fan-shaped sewage outlet 61 is 63cm, and the sewage flow rate is 850m 3 / hr, the speed of the mud scraper is 0.18r / min. After testing, the sludge concentration is 13 mg / l after being treated by the side water outlet mud scraper of the present invention, while the sludge concentration in the clear water of the traditional circumferential water outlet mud scraper is 20 mg / l, which greatly improves the sludge concentration. deposition effect.

Embodiment 3

[0019] In this example, the diameter of the sedimentation tank 1 is 50m, and the depth is 4.5m. The height h1 of the fan-shaped clear water outlet 13 of the sedimentation tank 1 is 25cm, and the fan-shaped angle of the fan-shaped clear water outlet 13 is 90 degrees. The angle is 150 degrees, the distance between the upper end of the fan-shaped sewage outlet 61 and the upper end of the sedimentation tank 1 is 1.5m, the height of the fan-shaped sewage outlet 61 is 68cm, and the sewage flow rate is 2120m 3 / hr, the speed of the mud scraper is 0.16r / min. After testing, the sludge concentration is 12.5 mg / l after being treated by the side water outlet mud scraper of the present invention, while the sludge concentration in the clear water of the traditional circumferential water outlet mud scraper is 23 mg / l, which greatly improves the sludge concentration. Mud deposition effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com