Linear light spot laser bend forming method of metal sheet

A metal sheet, bending forming technology, applied in laser welding equipment, metal processing equipment, heat treatment process control and other directions, to achieve the effect of large bending angle, short bending time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

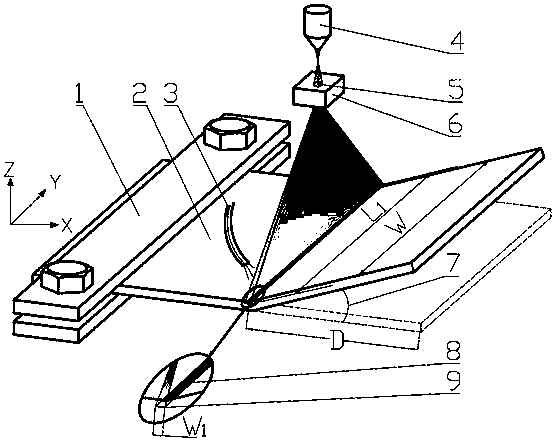

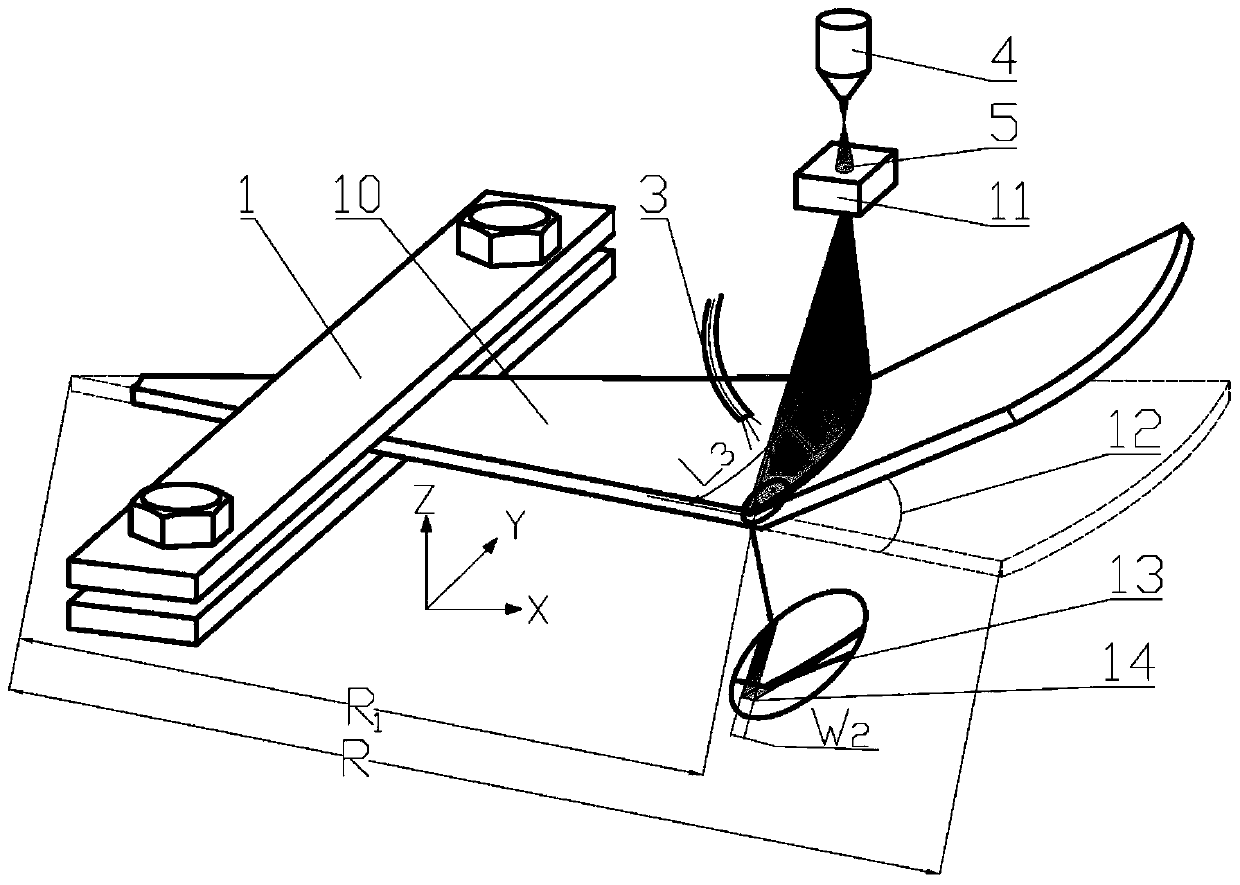

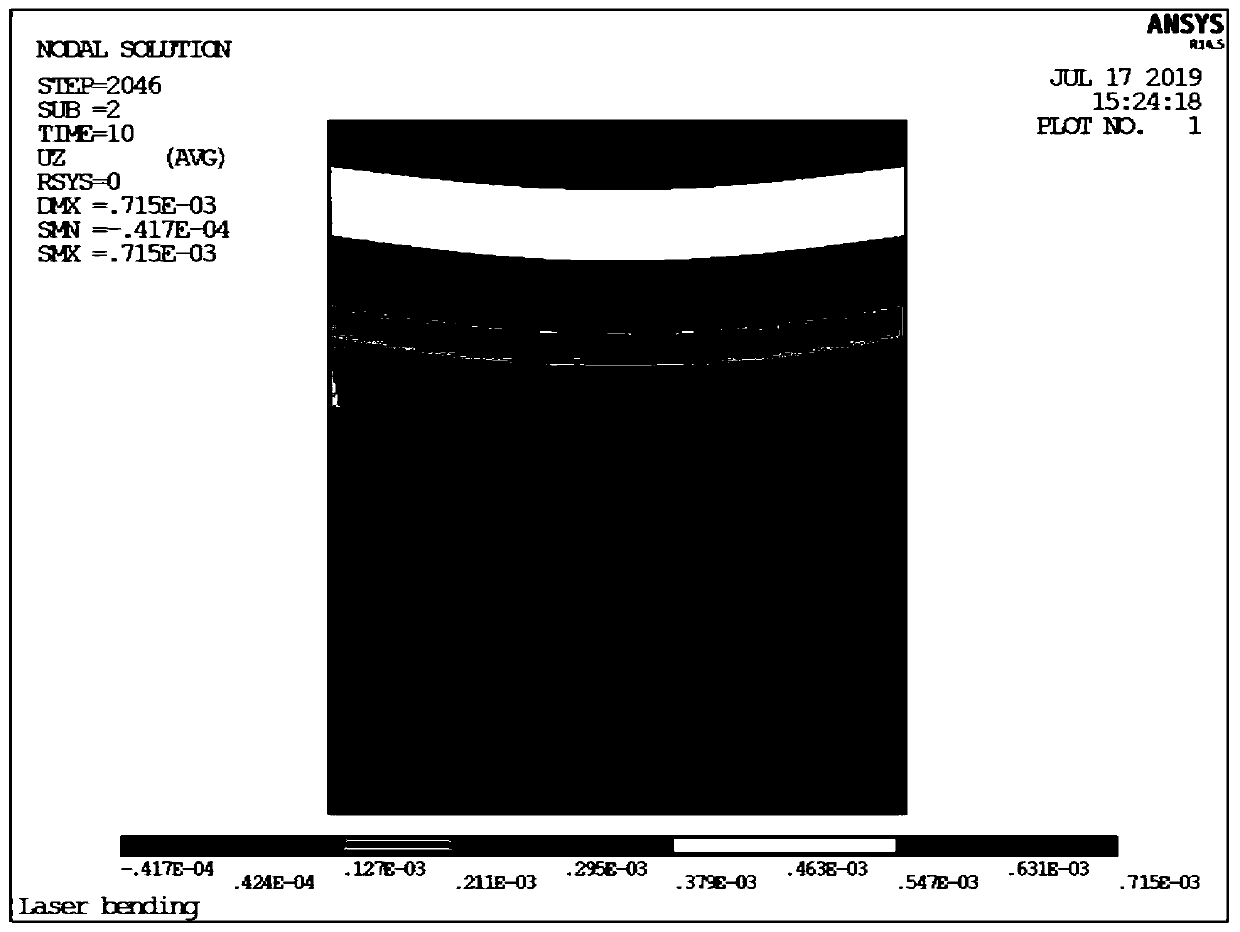

[0022] A method for laser bending forming of a linear spot of a thin metal plate according to the present invention, the principle of laser bending forming of a linear spot of a rectangular plate and a concentric circular arc line spot of a fan-shaped plate is respectively as follows figure 1 and figure 2 shown.

[0023] Specific steps are as follows:

[0024] Step 1: Workpiece preparation: According to the size and technical requirements, process a thin metal plate of the required specification, with a thickness of 1mm-2mm; for the rectangular plate 2, the length L is 40mm-120mm, and the width W is 30mm-100mm; for the fan-shaped plate 10 , the radius R of the outer circle is 50mm-200mm, the central angle n is 30°-60°; the plate thickness is 1mm-2mm.

[0025] Step 2: Line-type spot setting: For the stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com