Judgment method of the state of the secondary cooling system of continuous casting

A cooling system and state technology, which is applied in the field of judging the state of the secondary cooling system of continuous casting, can solve problems such as inability to achieve, and achieve the effects of improving production efficiency, convenient use and improving cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

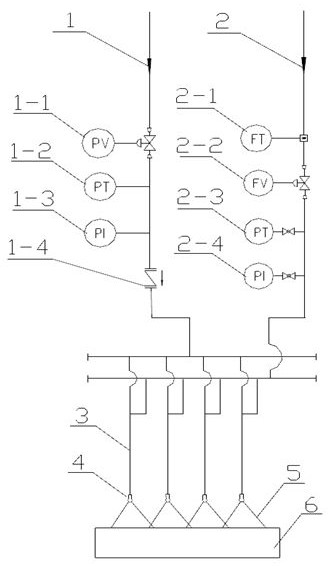

[0053] An enterprise uses 1# continuous casting machine, the inner arc of zone 5 of the secondary cooling system, the pressure of the secondary cooling air is 0.15MPa, and the flow rate of the secondary cooling water is 180L / min, the valve opening of the secondary cooling air measured by this circuit is 60%. After a certain period of production, under the same secondary cooling air pressure and secondary cooling water flow conditions, the opening of the pressure regulating valve 1-1 of this circuit is displayed as 10%, and the system sends out a serious blockage signal. Inspection found that up to 40% of the nozzles were clogged, and after replacement, the opening of the circuit pressure regulating valve 1-1 returned to 60% under the same conditions.

Embodiment 2

[0055] A certain enterprise uses 1# continuous casting machine, the outer arc of zone 7 of the secondary cooling system, when the pressure of the secondary cooling air is 0.15MPa, and the flow rate of the secondary cooling water is 120L / min, the opening of the valve of the secondary cooling air measured by this circuit is 55%. After a certain period of production, under the same secondary cooling air pressure and secondary cooling water flow conditions, the opening of the pressure regulating valve 1-1 of this circuit is displayed as 78%, and the system sends out a moderate leakage signal, and the secondary cooling system of the circuit is shut down. After the inspection, it was found that the secondary cold air pipe was ruptured and caused air leakage. After the air pipe was replaced, the opening of the pressure regulating valve 1-1 of the circuit returned to about 55% under the same conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com