Multi-spindle glass machining center

A machining center and multi-spindle technology, which is applied in the field of CNC machine tools, can solve the problems of high cost and large size, and achieve the effect of low cost, small size and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

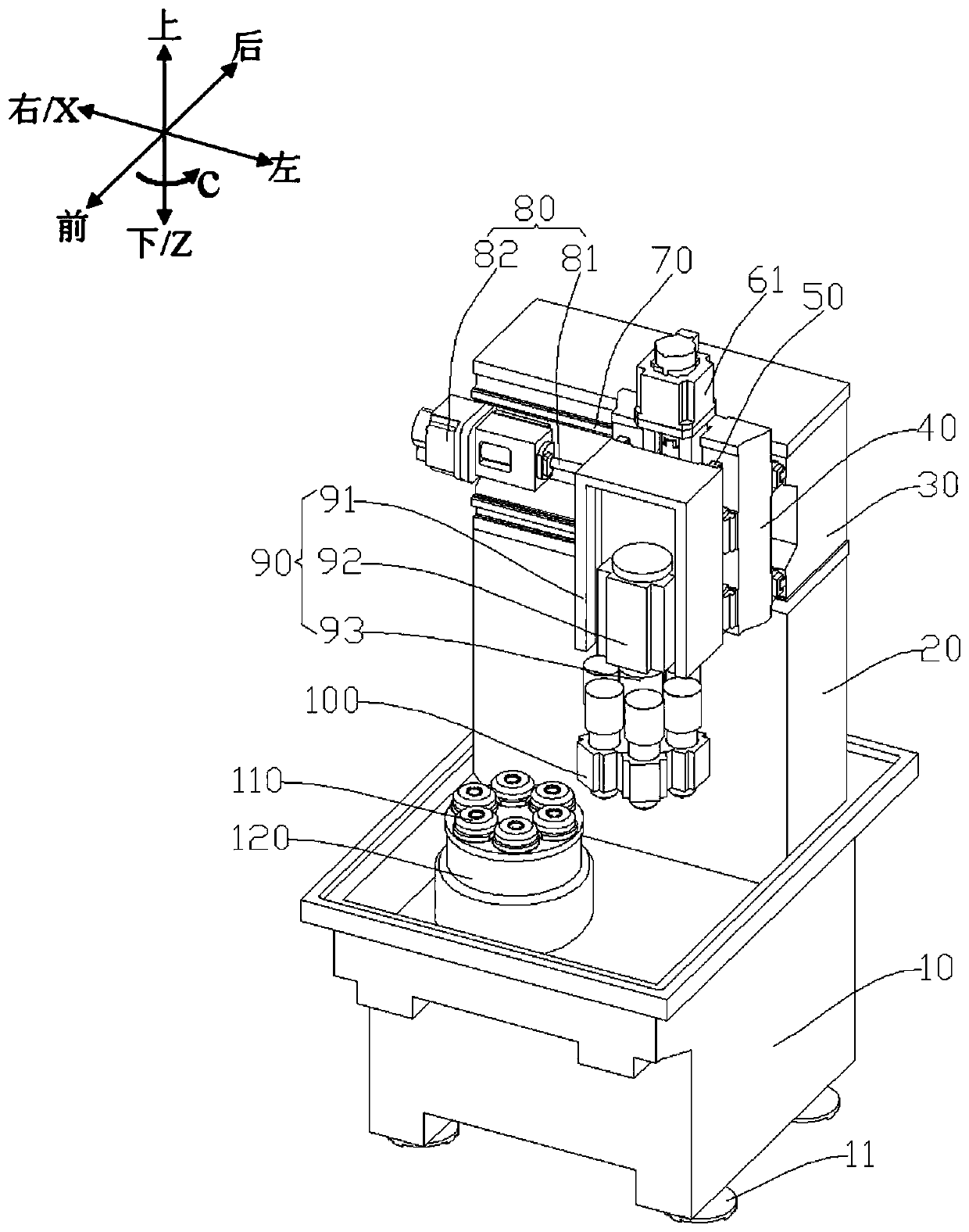

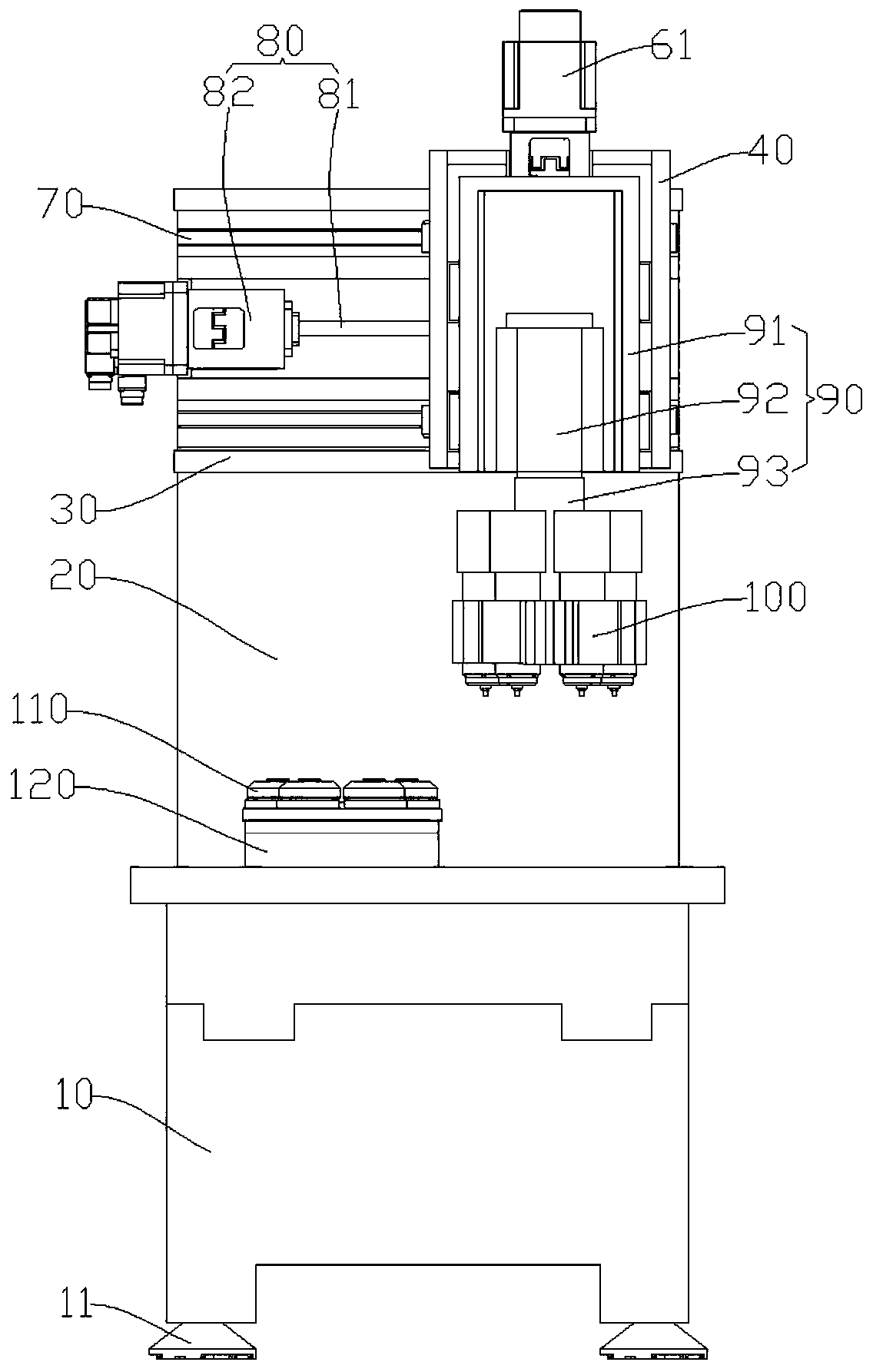

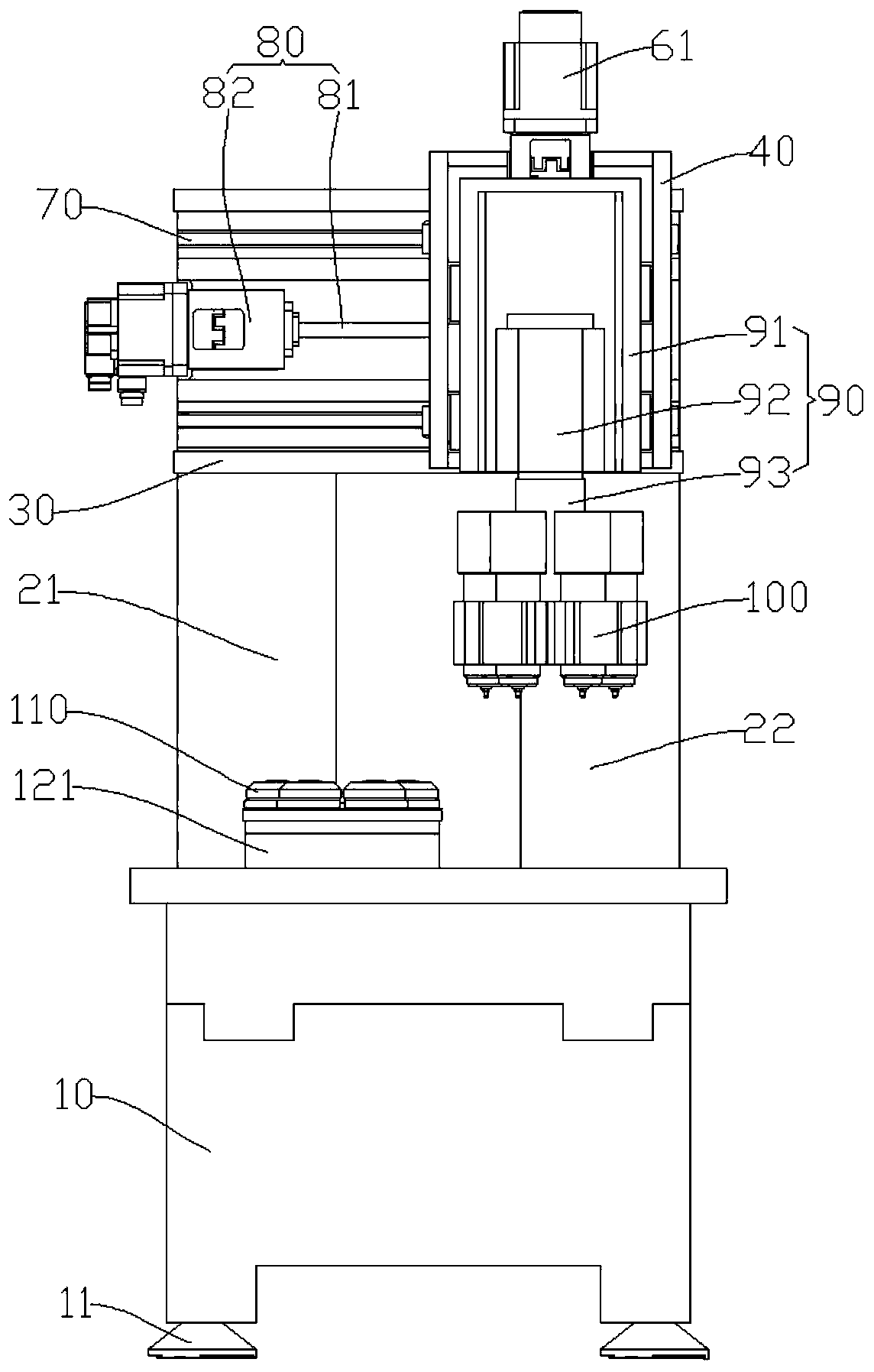

[0029] The glass processing center in this embodiment includes a bed 10 with a processing table base 120, a column 20 on the bed 10, a beam 30 with an X-axis guide rail 70 on the column 20, and a sliding The X-axis slide plate 40 with the Z-axis guide rail 50 on the X-axis guide rail 70, the spindle installation box 90 slidingly arranged on the Z-axis guide rail 50, also includes at least three processing tables 110, at least three processing spindles 100, X-axis drive Mechanism 80, Z-axis driving mechanism, and C-axis driving mechanism.

[0030] Such as figure 1 As shown, the definition of the glass processing center includes a horizontal X-axis, a vertical Z-axis and a C-axis where the processing table 110 rotates. The processing tables 110 are arranged on the processing table base 120 and distributed in the circumferential direction, and are used for clamping workpieces. The processing spindles 100 are installed on the spindle installation box 90, corresponding to the pro...

Embodiment 2

[0041] Example 2, such as figure 1 As shown, the glass processing center in this embodiment has six processing spindles 100 and six processing tables 110 corresponding to the processing spindles 100 . The six processing tables 110 are distributed in a circle and evenly arranged on the base 120 of the processing tables. The six processing spindles 100 correspond to the six processing tables 110 , are distributed in a circle, and are evenly distributed on the spindle installation box 90 . Simultaneous processing of six spindles improves work efficiency.

Embodiment 3

[0042] Example 3, such as figure 2 As shown, the glass processing center in this embodiment has a fourth driving mechanism 94 . The spindle installation box 90 includes a fourth driving mechanism 94 , a central shaft 93 and a box body 91 . The output end of the fourth driving mechanism 94 protrudes outside the box body 91 of the spindle installation box 90 in the negative direction of the Z axis. The processing spindles 100 are distributed in a circle and evenly arranged on the outer peripheral wall of the central shaft 93 . The fourth driving mechanism 94 is used to drive the central shaft 93 to rotate and drive the processing spindles 100 to revolve around the central shaft 93 at a low speed. A fourth drive mechanism 94 is provided in the spindle installation box 90 for driving the processing spindle 100 to rotate around the central axis 93 to increase the processing flexibility of the glass processing center.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap