Remote monitoring system and method for servo press production field

A remote monitoring system, servo press technology, applied in the direction of press, general control system, control/regulation system, etc., can solve the problems of high maintenance cost, poor real-time performance, complex design, etc., and achieve simple structure, reliable design principle, The effect of highlighting substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

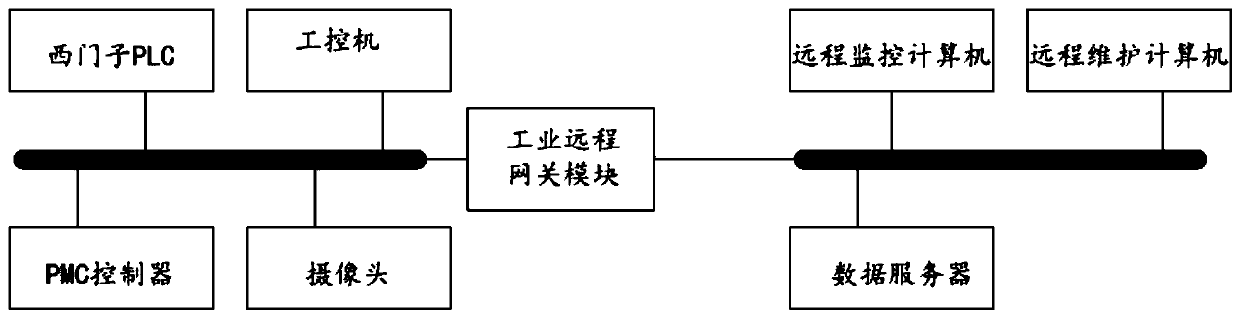

[0043] Such as figure 1 As shown, the technical solution of the present invention provides a remote monitoring system for the production site of a servo press, including a field device end and a remote monitoring end, and the field device end is connected to the remote monitoring end through an industrial remote gateway module; The equipment end includes on-site data acquisition terminal, industrial computer, and controller; the controller, on-site data acquisition terminal and industrial computer are connected with the industrial remote gateway module; The computer; the remote monitoring computer is provided with a network setting connection module and a remote monitoring software module; the on-site data collection terminal includes a sensor and a camera.

[0044]In this embodiment, the key to the production site hardware system is to build a hardware system with the industrial remote gateway module as the core. This system adopts Inhancom IR615-S series industrial router m...

Embodiment 2

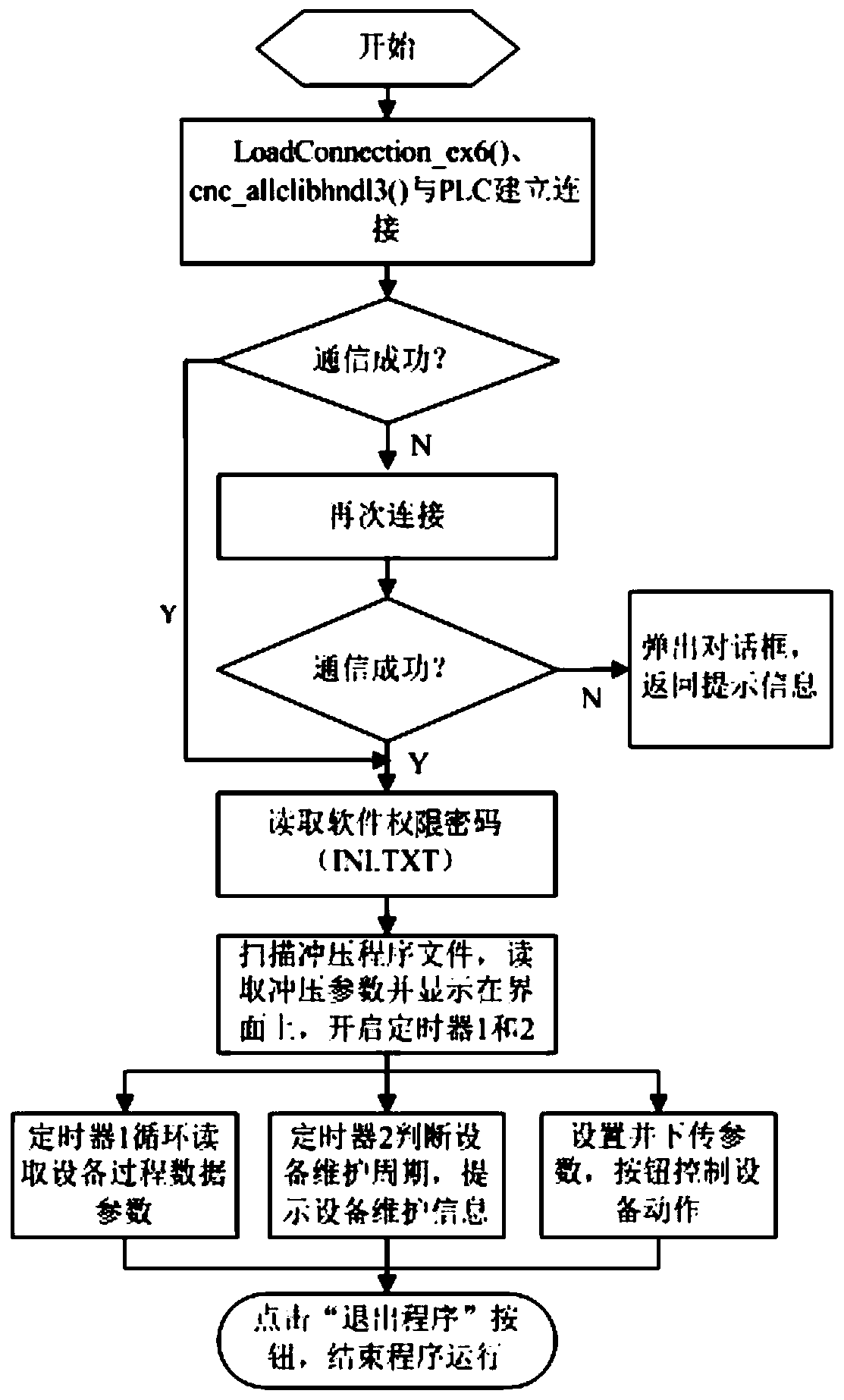

[0054] The technical solution of the present invention also provides a remote monitoring method for the production site of a servo press, which is applied to a remote monitoring system. The remote monitoring system includes a field device end and a remote monitoring end, and the field device end passes through an industrial remote gateway module. Connect to the remote monitoring terminal; the remote monitoring terminal includes a remote monitoring computer and a remote maintenance computer arranged in the same local area network; the method comprises the following steps:

[0055] S1: Connect the remote monitoring system to the network; connect each controller and network camera to the industrial remote gateway module and configure the gateway module, log in to the gateway access maintenance platform InHandCloud through a web browser to register an account, and log in after the registration is completed The account establishes a device virtual site, adds the controller device co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com