Compound type carbon steel pickling corrosion inhibitor and application thereof

A technology for pickling corrosion inhibitor and carbon steel, applied in the field of corrosion inhibitor, can solve the problem that the corrosion inhibitor is difficult to meet the requirements of pickling, and achieve the effect of high corrosion inhibition efficiency

Active Publication Date: 2019-10-11

ZHONGBEI UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, it is generally difficult for a single-component corrosion inhibitor to meet the pickling requirements. Therefore, it is necessary to design a compound corrosion inhibitor that can effectively improve the corrosion inhibition efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

[0050] A compound corrosion inhibitor is compounded by including the following raw materials, as shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

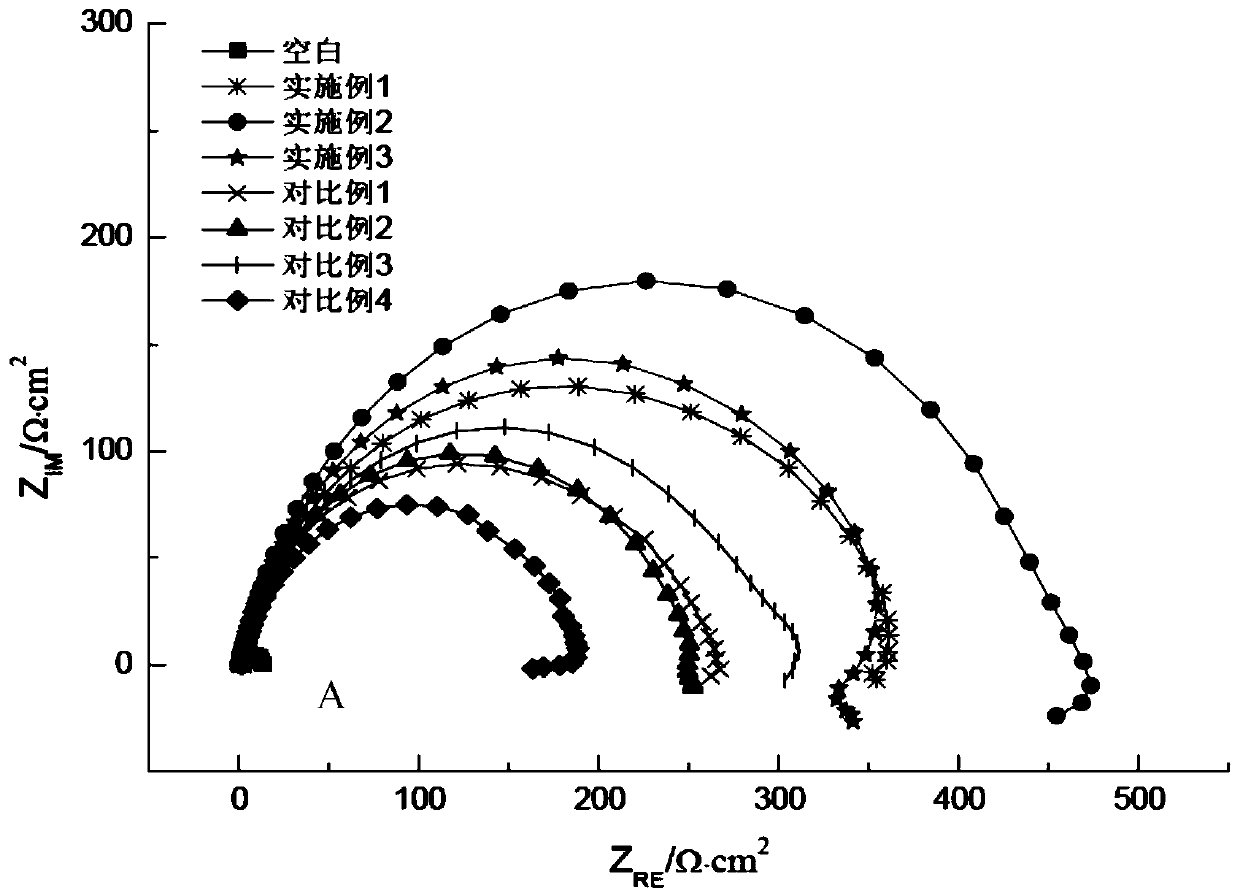

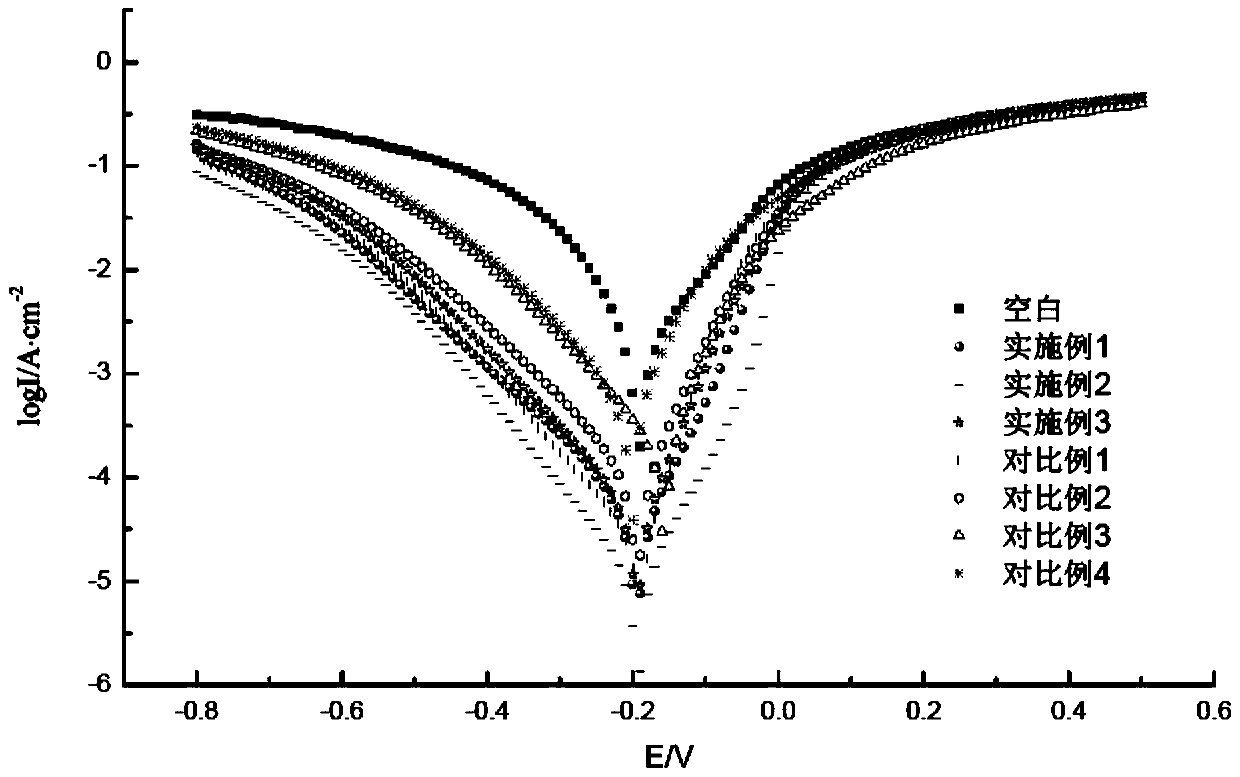

The invention provides a compound type carbon steel pickling corrosion inhibitor and application thereof and belongs to the technical field of corrosion inhibitors. The corrosion inhibitor comprises thiotriazinone-sulfonate-containing type surfactant, a heterocyclic compound and Tween, wherein the heterocyclic compound comprises at least one in 2-mercaptobenzothiazole and 2-aminobenzimidazole, andthe structure of the thiotriazinone-sulfonate-containing type surfactant is shown as the general formula (I), wherein n=5-11. The compound type carbon steel pickling corrosion inhibitor is mainly applied to carbon steel pickling, all the components which are the thiotriazinone-sulfonate-containing type surfactant, the small molecule heterocyclic compound and the Tween interact synergistically, thus a compact adsorption layer is formed on the surface of carbon steel, and the corrosion inhibition effect of the corrosion inhibitor on the carbon steel is improved.

Description

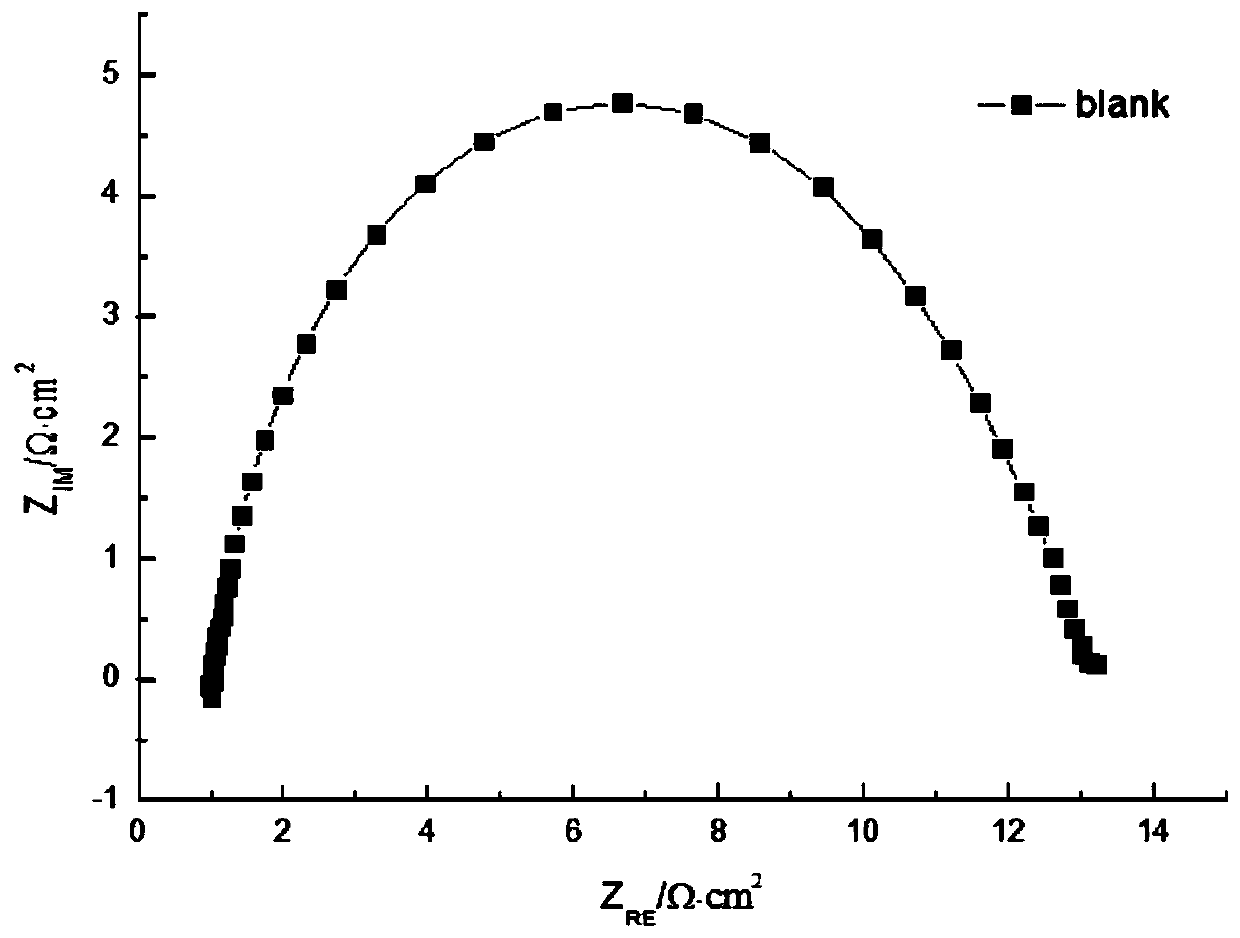

Technical field [0001] The invention belongs to the technical field of corrosion inhibitors, and specifically relates to a compound type carbon steel pickling corrosion inhibitor and its application. Background technique [0002] Among various metal materials, carbon steel is cheap and easy to smelt, and can meet most engineering requirements, so it is widely used in all aspects of machinery manufacturing. However, in the process of casting, forging, welding and heat treatment of carbon steel, a dense and strong adhesion oxide layer is easily formed on the surface of carbon steel, which affects its appearance and performance and must be removed. [0003] Pickling is one of the important means to remove the oxide layer on the surface of carbon steel. However, in order to prevent the "over-corrosion" phenomenon of the pickling process from causing the loss of steel materials, or to avoid the increase in surface roughness, and the hydrogen embrittlement of the metal surface, it is ec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23G1/06C23G1/08

CPCC23G1/06C23G1/08

Inventor 朱海林李晓芬陈肖杰王京宝马雪梅胡志勇

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com