Bolt drum type spherical shell node for circular steel pipe support connection

A spherical shell and round steel pipe technology, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of complex construction process, stress concentration phenomenon, and high requirements for joint processing accuracy, and achieve high efficiency, reasonable design, and high practicality. and the effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

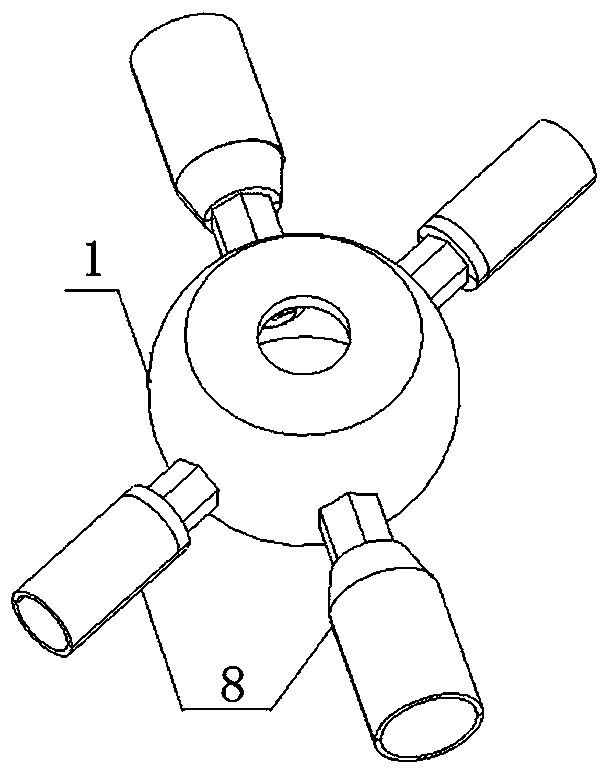

[0048] Such as figure 1 As shown, a round steel pipe support connection bolt drum spherical shell node, including a drum spherical shell 1 and N connecting components 8 .

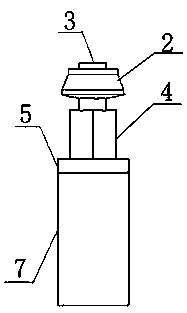

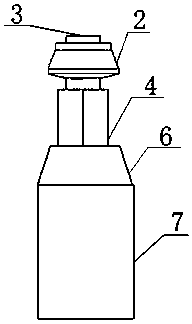

[0049] Such as Figure 2a , 2b As shown, each connection assembly 8 includes a curved surface European nut 2, a high-strength bolt 3 for the grid, a sleeve 4, a sealing plate 5 (or a cone head 6), a round steel pipe rod 7; one end of the round steel pipe rod 7 is connected to One end of the sealing plate 5 (or the cone head 6) is fixedly connected (connect the large diameter end of the cone head when connecting the cone head), and the high-strength bolts 3 for the network frame are preset in the bolt holes of the sealing plate 5 (or the cone head 6), The sleeve 4 is fixedly connected to the pre-set high-strength bolt 3 for the network frame by fastening screws, and the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap