Artificial carbonate rock core with developed secondary pores and preparation method thereof

A carbonate rock and core technology is applied in the field of artificial carbonate rock core and its preparation, which can solve the problems of unsatisfactory and difficult to accurately describe the seepage characteristics of carbonate rock reservoirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

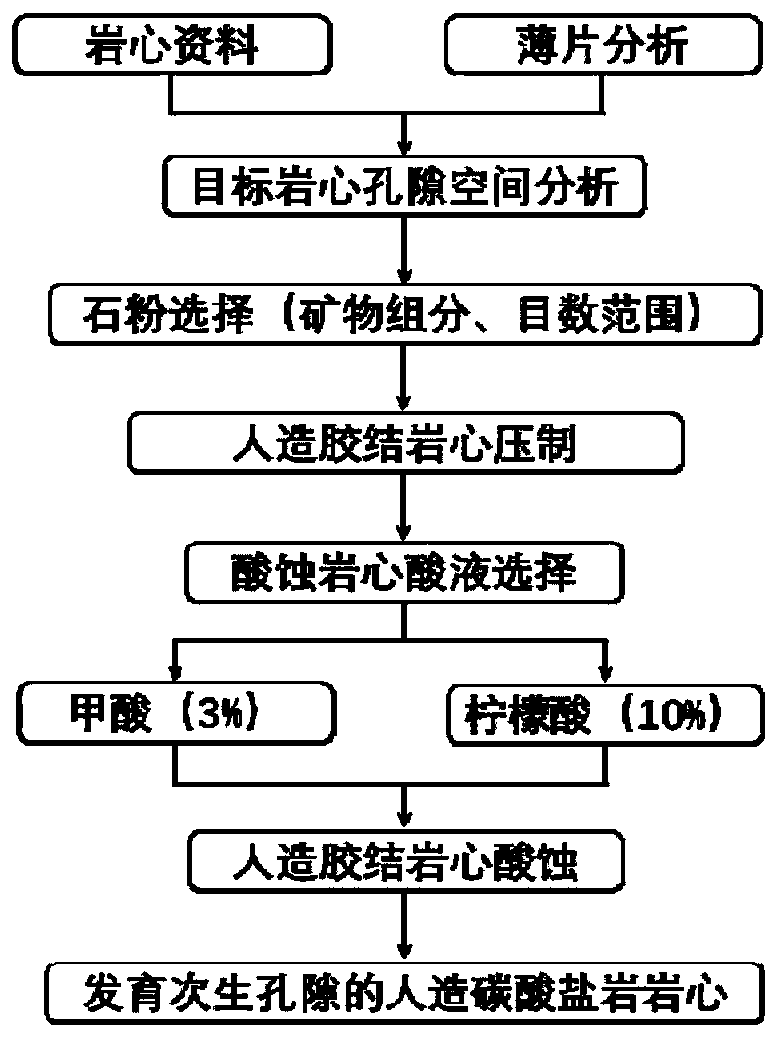

[0043] Production process such as figure 1 shown.

[0044] (1) Analysis of reservoir geological data

[0045] According to the geological data of the reservoir, the core data and thin section data are analyzed to obtain the types of core minerals in the original target reservoir, the volume percentage of various minerals, and the primary porosity, secondary porosity and permeability of the target core.

[0046] Specific analysis of a target rock sample: through XRD testing, the target core is pure component limestone; thin section data shows that the primary porosity of the core is 17%, and the secondary porosity is 3%; the permeability of the core is 231mD.

[0047] (2) stone powder selection

[0048]According to the core mineral type of the target reservoir, the ratio between dolomite and limestone is quantitatively controlled in proportion. The mineral raw materials of the above-mentioned dolomite and limestone can be obtained through outcropping in the field, or they ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com