Concrete flaw detection device and flaw detector

A flaw detection device and concrete technology, applied in the field of nuclear technology, can solve the problems of immature reinforced concrete, neutron shielding and imperfect detection schemes, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

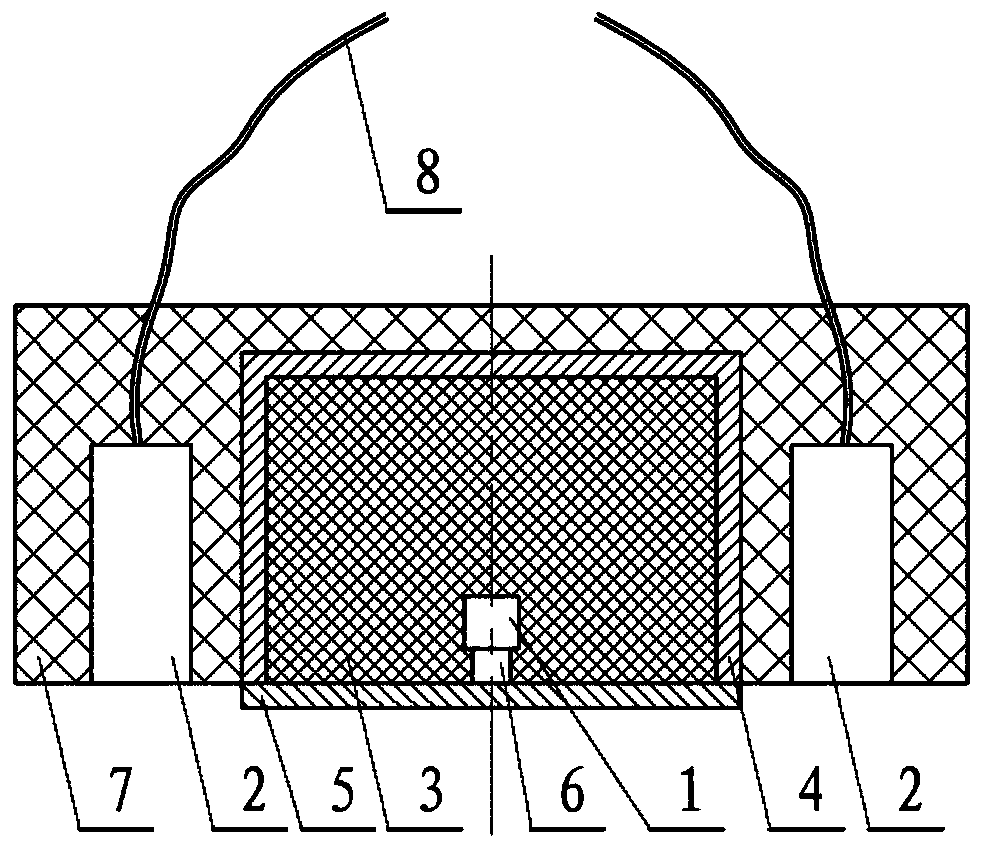

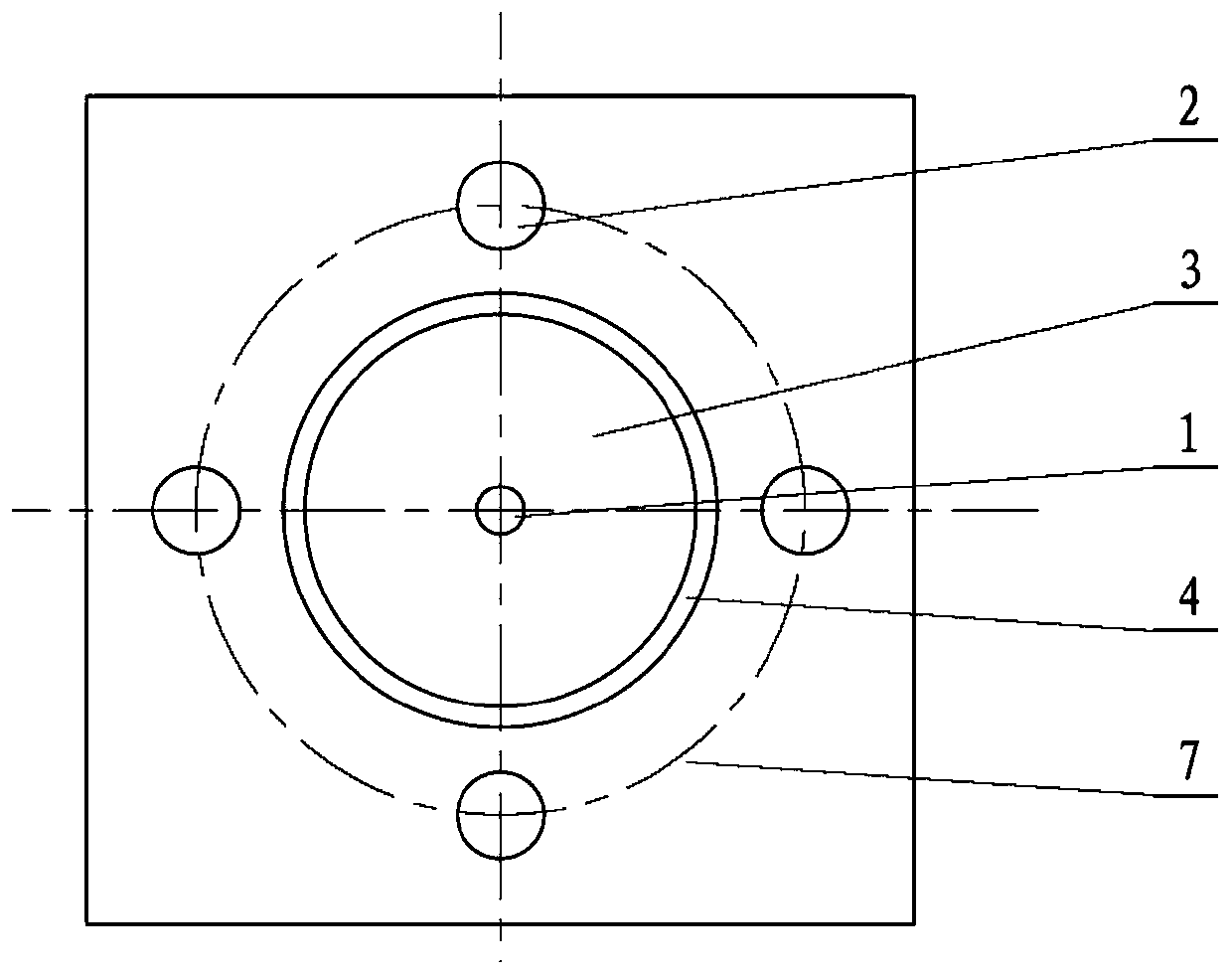

[0031] Such as figure 1 and figure 2 As shown, a concrete flaw detection device is installed on a flaw detector as a probe, and is suitable for flaw detection of a concrete structure covered with a steel plate of a certain thickness, including a neutron source 1, four detectors 2 and a shielding body 3; The neutron source 1 is set at the center of the shielding body 3, surrounded by the shielding body 3, and four detectors 2 are equally spaced outside the shielding body 3 along the circumferential direction of the center of the neutron source 1. Specifically, they can all be installed in a base body 7, and the base body 7 can be a housing of a probe or the like. The flaw detector also includes some lines 8 and data acquisition interfaces, etc., to transmit the data to the computer, and then analyze it through software, which all belong to the known technology and will not be described in detail. The protection scope of this embodiment lies in the concrete flaw detection devi...

Embodiment 2

[0046] A flaw detector includes the concrete flaw detector described in the first embodiment.

[0047] The working process of the flaw detector is: place the concrete flaw detection device of the flaw detector on the surface of the detected object (concrete), start flaw detection, and the computer counts the neutrons detected by the four detectors within a period of time, and finally statistically analyzes the results , according to the detector count and the response map of the cavity depth and position, it can be analyzed whether there is a defect in the detected object. This neutron backscatter flaw detection instrument is suitable for flaw detection of concrete structures covered with steel plates of a certain thickness.

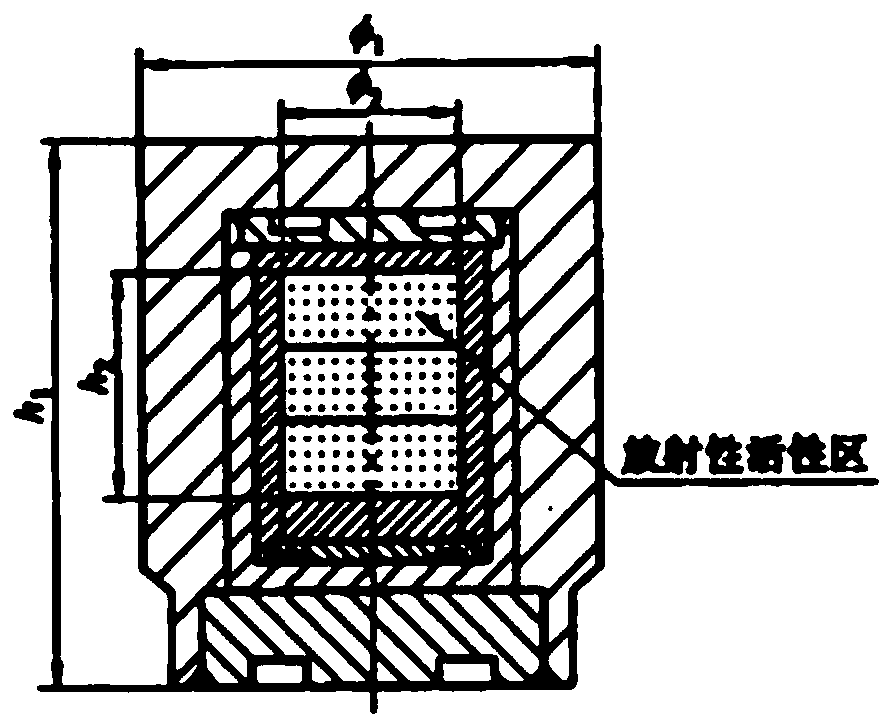

[0048] Such as Figure 4As shown, the initial shield design with a radius thickness of 15cm and a B4C mass content of 0.1 can make the proportion of backscattered particles reach 20%, which makes the detector readings of neutron backscattering flaw dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com