Semi-potting transparent high-voltage and high-frequency transformer structure capable of serialization

A high-voltage, high-frequency, transformer technology, applied in the direction of fixed transformers or mutual inductance, transformer/inductor cores, transformer/inductor components, etc., can solve the problems of high-frequency transformer loss density, damaged insulation, and complex design. Achieve the effects of reducing winding loss density, enhancing heat dissipation, and reducing total winding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

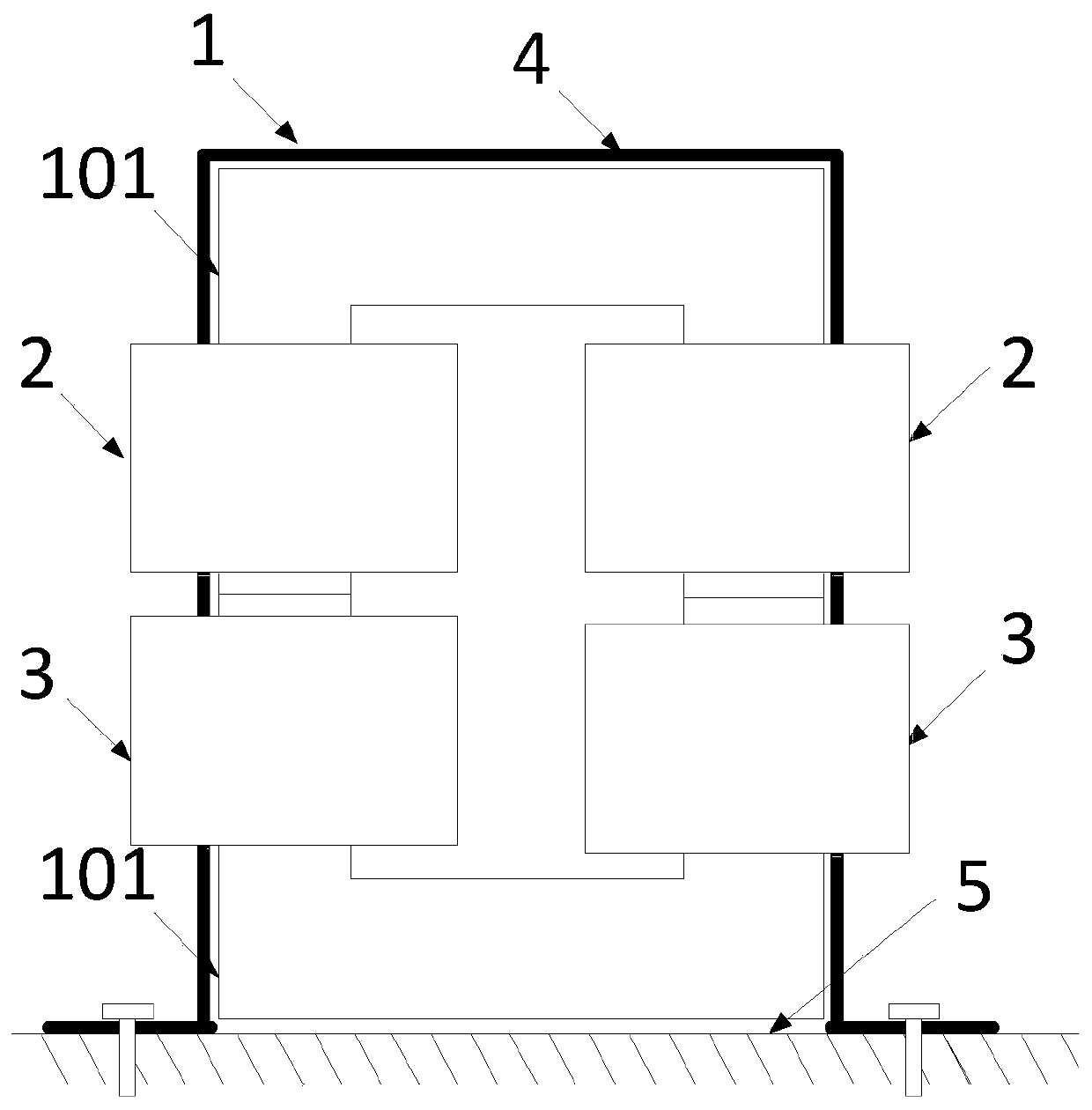

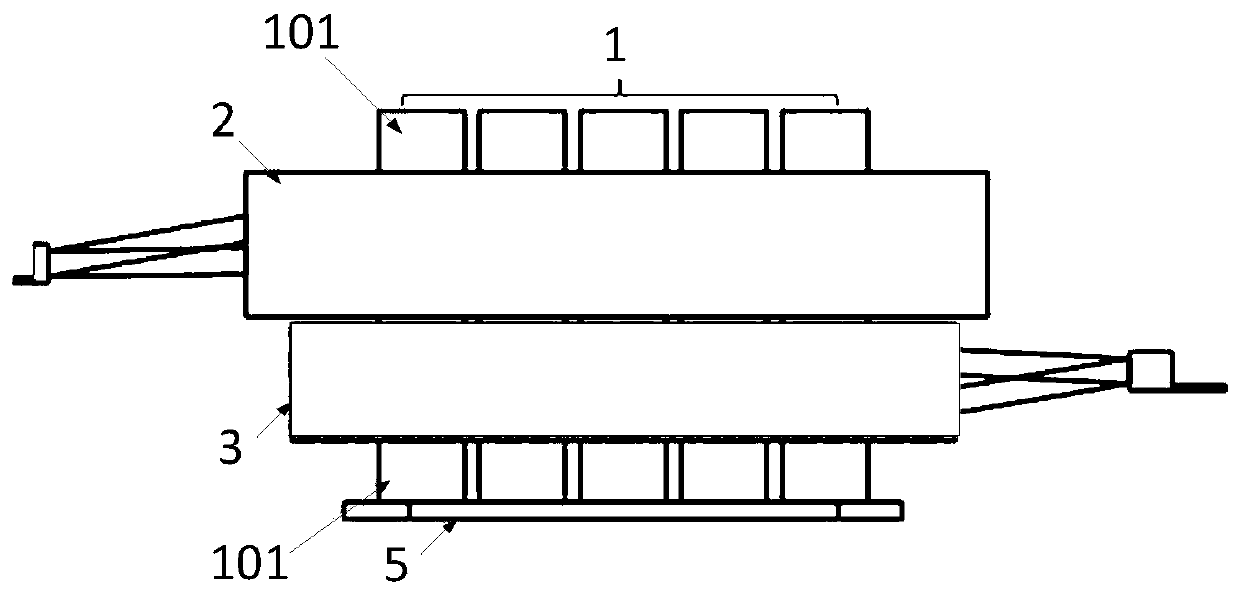

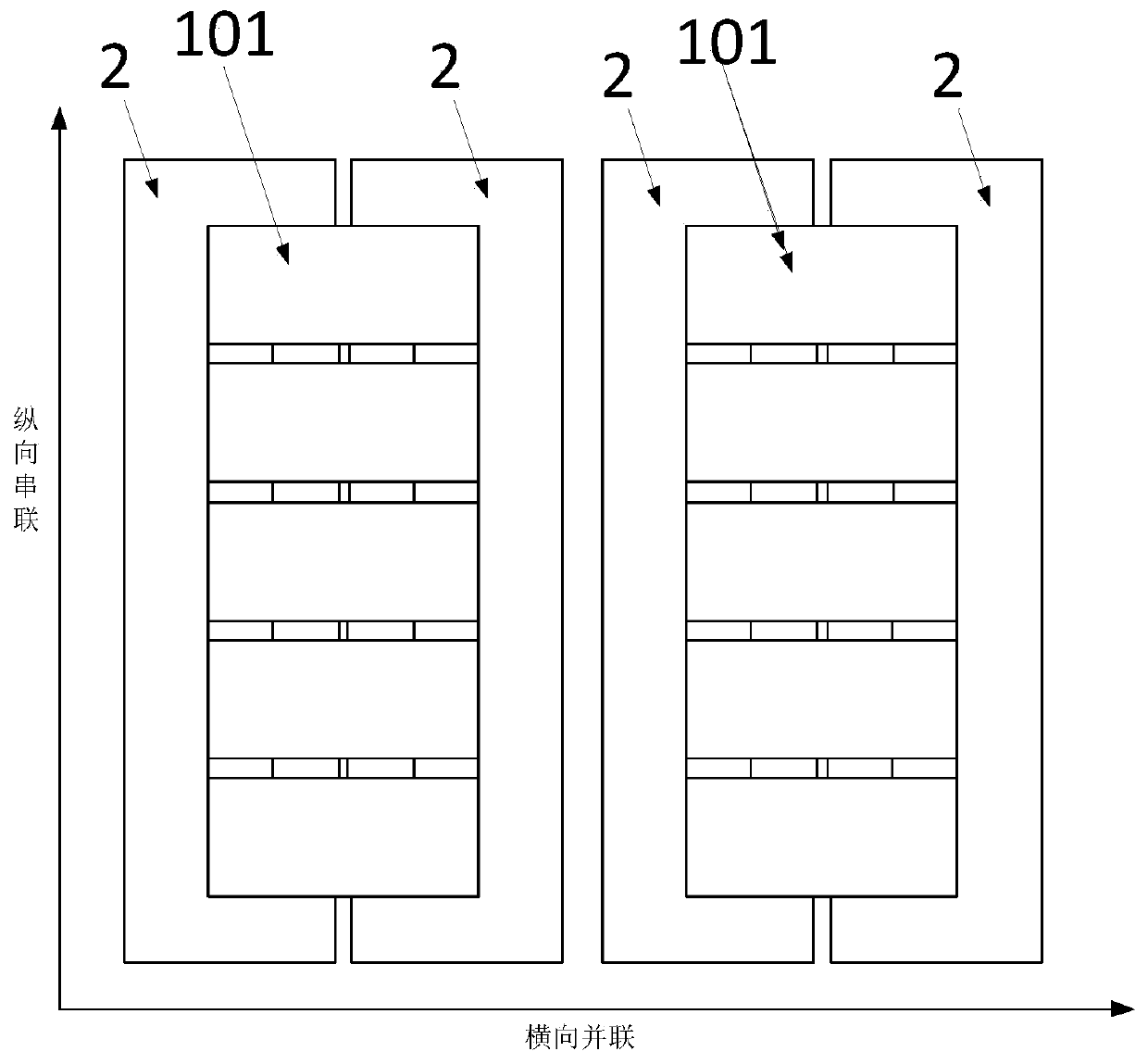

[0039] Taking an 80kVA / 20kHz high frequency transformer as an example, follow the steps below to realize the heat dissipation enhanced modular high frequency transformer structure.

[0040] Step 1: Selection of core material and winding material.

[0041] The loss density of ferrite gradually decreases as the temperature rises. At about 90 to 100 degrees Celsius, the loss density reaches the lowest, and it is lower than that of nanocrystalline materials. In actual operation, the temperature of the iron core is about 100°C, which is just right at the lower point of the iron core loss density. Litz wire can better eliminate the effect of skin effect under high frequency conditions, and the insulating layer on the surface of Litz wire can provide a certain degree of insulation strength. Flat copper tape needs to use insulating tape to provide additional insulation, which is Come trouble.

[0042] Step 2: Selection of insulation framework material and pouring material.

[0043] In order...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com