A heat dissipation device for a multi-layer circuit board

A multi-layer circuit board and heat dissipation device technology, which is applied to circuit heating devices, printed circuit components, electrical components, etc., can solve problems affecting the use effect of electronic products, traditional multi-layer circuit boards, unfavorable circuit board heat dissipation, etc., to achieve Realize heat loss, avoid heat accumulation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

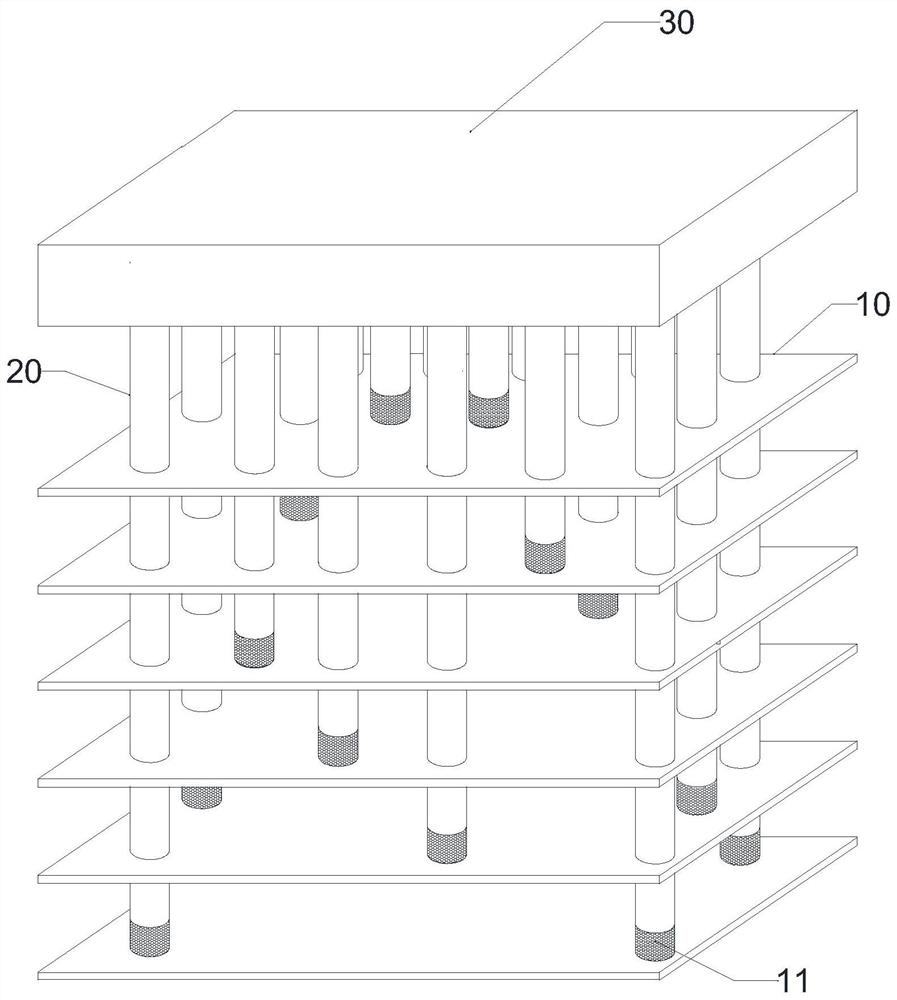

[0019] This embodiment provides a heat dissipation device for a multi-layer circuit board, which includes a plurality of circuit board bodies 10 with the same specifications, and a plurality of electronic chips 11 are arranged on the circuit board body 10, and also includes a plurality of heat dissipation rods 20 and at least one The heat sink 30, the circuit board body 10 is stacked in parallel in order to form a multi-layer circuit board according to the same orientation of the electronic chips 11 arranged on the surface, and the multi-layer circuit board has an outward facing electronic chip 11 on the side of the circuit board body 10 A heat sink 30 is provided; one end of the heat dissipation rod 20 is attached to the electronic chip 11 , and the other end passes through the rear heat sink body in turn until the heat sink 30 , so as to rapidly dissipate heat from the electronic chip 11 .

[0020] Further, the circuit board body 10 includes a first circuit board body 10 fart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com